What is Global 3D Printed Timing Belt Market?

The Global 3D Printed Timing Belt Market represents a fascinating intersection of advanced manufacturing technology and traditional mechanical components. Timing belts are crucial in various machinery, ensuring synchronized movement between different parts. Traditionally made from rubber or polyurethane, these belts have now entered the realm of 3D printing, which allows for more customized and precise production. The global market for these 3D printed timing belts is expanding as industries recognize the benefits of 3D printing, such as reduced waste, faster production times, and the ability to create complex geometries that were previously difficult or impossible to achieve. This market is driven by the increasing demand for efficient and durable components in sectors like automotive, aerospace, and industrial machinery. As 3D printing technology continues to evolve, the potential for innovation in timing belt design and application grows, offering new opportunities for manufacturers and end-users alike. The shift towards 3D printed timing belts is not just a trend but a significant advancement in manufacturing, promising enhanced performance and sustainability.

5mm Width Type, 6mm Width Type, Others in the Global 3D Printed Timing Belt Market:

In the Global 3D Printed Timing Belt Market, different width types cater to various applications and requirements. The 5mm width type is often favored for its versatility and adaptability in smaller machinery and devices. This width is particularly useful in applications where space is limited, yet precision and reliability are paramount. Industries such as robotics and small-scale automation systems benefit from the 5mm width type due to its ability to fit into compact spaces without compromising on performance. The 6mm width type, on the other hand, is slightly broader and is typically used in applications that require a bit more strength and durability. This width is ideal for medium-sized machinery where the balance between size and power is crucial. It offers a robust solution for industries like automotive and industrial equipment, where timing belts must withstand higher loads and more demanding conditions. Beyond these specific widths, the market also includes other types that cater to niche applications. These might include custom widths or specialized materials designed for unique environments, such as high-temperature or chemical-resistant settings. The diversity in width types within the 3D printed timing belt market highlights the technology's adaptability and the ability to meet a wide range of industrial needs. Each width type offers distinct advantages, allowing manufacturers to choose the best option for their specific application, ensuring optimal performance and longevity. As the market continues to grow, the development of new materials and printing techniques will likely expand the range of available width types, further enhancing the versatility and applicability of 3D printed timing belts.

Industrial, Home Use, Others in the Global 3D Printed Timing Belt Market:

The usage of 3D printed timing belts spans various areas, each benefiting from the unique advantages offered by this technology. In the industrial sector, these belts are crucial components in machinery and equipment, providing precise and reliable motion control. Industries such as automotive, aerospace, and manufacturing rely on timing belts to ensure the smooth operation of engines, conveyors, and other mechanical systems. The ability to 3D print these belts allows for customization to specific machinery requirements, improving efficiency and reducing downtime. In home use, 3D printed timing belts are finding their way into appliances and consumer electronics. Devices such as 3D printers, washing machines, and even some kitchen appliances utilize timing belts for their operation. The precision and durability of 3D printed belts enhance the performance and lifespan of these products, offering consumers reliable and efficient solutions. Additionally, the ability to produce these belts on-demand means that replacements can be quickly and easily manufactured, reducing the need for large inventories and minimizing waste. Beyond industrial and home use, 3D printed timing belts are also being explored in other areas, such as medical devices and robotics. In the medical field, timing belts are used in equipment like imaging machines and surgical robots, where precision and reliability are critical. The customization capabilities of 3D printing allow for the creation of belts that meet the stringent requirements of medical applications. In robotics, timing belts are essential for the movement and control of robotic arms and other components, and 3D printing offers the flexibility to design belts that fit specific robotic configurations. Overall, the usage of 3D printed timing belts across these areas highlights the technology's versatility and potential to revolutionize traditional manufacturing processes.

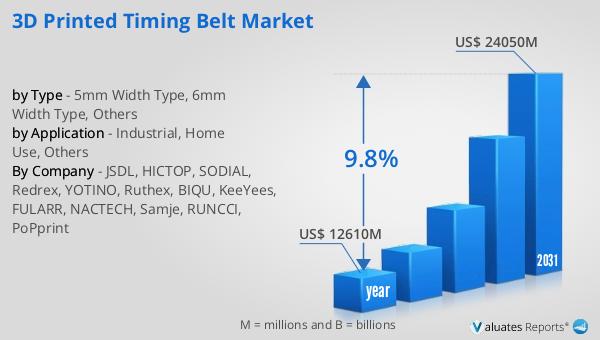

Global 3D Printed Timing Belt Market Outlook:

The global market for 3D Printed Timing Belts was valued at approximately $12.61 billion in 2024, and it is anticipated to grow significantly, reaching an estimated $24.05 billion by 2031. This growth represents a compound annual growth rate (CAGR) of 9.8% over the forecast period. This impressive expansion is driven by the increasing adoption of 3D printing technology across various industries, which is transforming the way timing belts are designed and manufactured. The ability to produce highly customized and precise components is a key factor contributing to the market's growth. As industries continue to seek more efficient and sustainable manufacturing solutions, the demand for 3D printed timing belts is expected to rise. This market outlook underscores the potential for innovation and development within the sector, as manufacturers explore new materials and printing techniques to enhance the performance and durability of timing belts. The projected growth of the market reflects the broader trend towards digital manufacturing and the increasing importance of 3D printing in modern production processes. As the technology continues to evolve, the global market for 3D printed timing belts is poised for continued expansion, offering new opportunities for manufacturers and end-users alike.

| Report Metric | Details |

| Report Name | 3D Printed Timing Belt Market |

| Accounted market size in year | US$ 12610 million |

| Forecasted market size in 2031 | US$ 24050 million |

| CAGR | 9.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | JSDL, HICTOP, SODIAL, Redrex, YOTINO, Ruthex, BIQU, KeeYees, FULARR, NACTECH, Samje, RUNCCI, PoPprint |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |