What is Global Electric Lifting Platform Market?

The Global Electric Lifting Platform Market refers to the worldwide industry that focuses on the production, distribution, and utilization of electric lifting platforms. These platforms are mechanical devices powered by electricity, designed to lift and lower heavy loads with ease and precision. They are commonly used in various sectors such as logistics, warehousing, construction, and manufacturing to enhance operational efficiency and safety. The market encompasses a wide range of products, including scissor lifts, boom lifts, and vertical mast lifts, each tailored to specific applications and requirements. The increasing demand for automation and the need for safer working environments are driving the growth of this market. Additionally, advancements in technology, such as the integration of IoT and AI, are further propelling the adoption of electric lifting platforms globally. The market is characterized by the presence of several key players who are continuously innovating to offer more efficient and cost-effective solutions.

Telescopic Arm Type, Folding Arm Type in the Global Electric Lifting Platform Market:

The Global Electric Lifting Platform Market includes various types of platforms, among which the Telescopic Arm Type and Folding Arm Type are prominent. Telescopic Arm Type platforms are designed with extendable arms that can reach significant heights, making them ideal for tasks that require vertical reach and precision. These platforms are commonly used in construction and maintenance work, where accessing high and hard-to-reach areas is crucial. The telescopic arm's ability to extend and retract allows for greater flexibility and maneuverability, making it a preferred choice for many industries. On the other hand, Folding Arm Type platforms are characterized by their articulated arms that can fold and unfold, providing a versatile range of motion. These platforms are particularly useful in confined spaces where maneuverability is limited. The folding arm design allows for easy navigation around obstacles and provides a stable platform for workers to perform their tasks. Both types of platforms are equipped with advanced safety features, such as emergency stop buttons, overload protection, and non-slip surfaces, ensuring the safety of operators. The choice between Telescopic Arm Type and Folding Arm Type platforms depends on the specific requirements of the task at hand. For instance, tasks that require reaching high elevations with minimal horizontal movement may benefit more from Telescopic Arm Type platforms, while tasks that involve working in tight spaces with the need for horizontal and vertical movement may find Folding Arm Type platforms more suitable. The versatility and efficiency of these platforms make them indispensable tools in various industries, contributing to the overall growth of the Global Electric Lifting Platform Market.

Logistics and Warehouse, Architecture, Manufacturing, Others in the Global Electric Lifting Platform Market:

The usage of Global Electric Lifting Platform Market spans across various sectors, including Logistics and Warehouse, Architecture, Manufacturing, and others. In the Logistics and Warehouse sector, electric lifting platforms are essential for handling and transporting goods efficiently. They help in loading and unloading heavy items, organizing inventory, and optimizing storage space. The ability to lift and move large volumes of goods with precision reduces the risk of damage and enhances productivity. In the Architecture sector, electric lifting platforms are used for construction, maintenance, and inspection of buildings. They provide a safe and stable platform for workers to perform tasks at elevated heights, such as painting, window cleaning, and structural repairs. The use of these platforms ensures that work is carried out efficiently and safely, minimizing the risk of accidents. In the Manufacturing sector, electric lifting platforms play a crucial role in assembly lines, material handling, and equipment maintenance. They enable workers to lift and position heavy components accurately, improving the overall efficiency of the production process. The platforms' ability to handle heavy loads with ease reduces the physical strain on workers and enhances workplace safety. Other sectors that benefit from electric lifting platforms include the entertainment industry, where they are used for setting up stages and lighting, and the aviation industry, where they assist in aircraft maintenance and repairs. The versatility and efficiency of electric lifting platforms make them valuable assets in various industries, contributing to improved operational efficiency and safety.

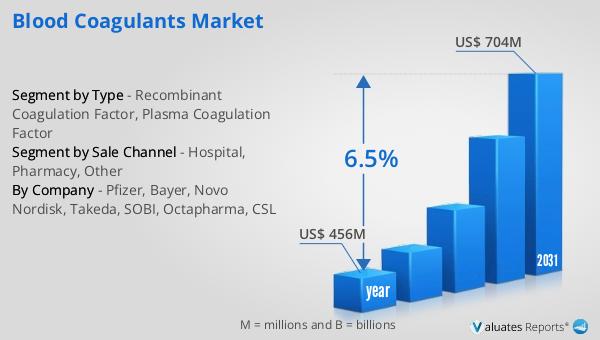

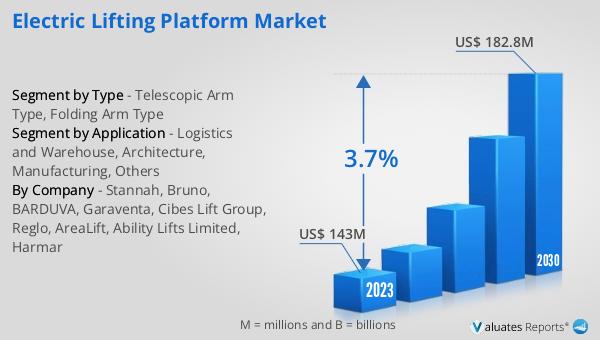

Global Electric Lifting Platform Market Outlook:

The global Electric Lifting Platform market was valued at US$ 143 million in 2023 and is anticipated to reach US$ 182.8 million by 2030, witnessing a CAGR of 3.7% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by increasing demand for automation and safer working environments. The market's expansion is supported by advancements in technology, such as the integration of IoT and AI, which enhance the functionality and efficiency of electric lifting platforms. The presence of several key players in the market, who are continuously innovating to offer more efficient and cost-effective solutions, also contributes to this growth. The projected increase in market value reflects the growing adoption of electric lifting platforms across various industries, including logistics, warehousing, construction, and manufacturing. The steady CAGR of 3.7% underscores the market's resilience and potential for sustained growth in the coming years.

| Report Metric | Details |

| Report Name | Electric Lifting Platform Market |

| Accounted market size in 2023 | US$ 143 million |

| Forecasted market size in 2030 | US$ 182.8 million |

| CAGR | 3.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Stannah, Bruno, BARDUVA, Garaventa, Cibes Lift Group, Reglo, AreaLift, Ability Lifts Limited, Harmar |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |