What is Global Solid-state Battery Laser System Market?

The Global Solid-state Battery Laser System Market is an emerging sector that focuses on the development and application of laser technologies specifically designed for solid-state batteries. Solid-state batteries are a type of battery technology that uses solid electrodes and a solid electrolyte, unlike traditional batteries that use liquid or gel electrolytes. This technology is gaining traction due to its potential for higher energy density, improved safety, and longer lifespan compared to conventional lithium-ion batteries. The laser systems in this market are crucial for manufacturing processes, such as cutting, welding, and drying, which are essential for the precise and efficient production of solid-state batteries. These laser systems enable manufacturers to achieve high precision and control, which are vital for the intricate designs and materials used in solid-state batteries. As industries like electric vehicles, consumer electronics, and renewable energy storage increasingly adopt solid-state batteries, the demand for advanced laser systems is expected to grow. This market is characterized by continuous innovation and technological advancements, aiming to enhance the efficiency and scalability of solid-state battery production. The integration of laser systems in the manufacturing process not only improves the quality of the batteries but also reduces production costs and time, making it a pivotal component in the future of energy storage solutions.

Laser Cutting Equipment, Laser Drying Equipment, Others in the Global Solid-state Battery Laser System Market:

Laser Cutting Equipment, Laser Drying Equipment, and other laser technologies play a significant role in the Global Solid-state Battery Laser System Market. Laser Cutting Equipment is essential for the precise shaping and sizing of battery components. In solid-state batteries, where the materials and structures are more complex than traditional batteries, laser cutting provides the accuracy needed to ensure that each component fits perfectly within the battery assembly. This precision is crucial for maintaining the integrity and performance of the battery, as even minor deviations can lead to significant performance issues or safety hazards. Laser cutting also allows for the efficient use of materials, reducing waste and lowering production costs. On the other hand, Laser Drying Equipment is used in the manufacturing process to remove moisture from battery components. Moisture can be detrimental to the performance and longevity of solid-state batteries, as it can lead to corrosion and other chemical reactions that degrade the battery over time. Laser drying offers a non-contact method of moisture removal, ensuring that the delicate components of the battery are not damaged during the drying process. This method is also faster and more energy-efficient than traditional drying techniques, making it an attractive option for manufacturers looking to optimize their production lines. Other laser technologies in this market include laser welding and laser marking. Laser welding is used to join battery components together with high precision and strength. This is particularly important in solid-state batteries, where the materials used can be difficult to weld using traditional methods. Laser welding provides a clean and efficient way to create strong, reliable connections between components, ensuring the overall durability and performance of the battery. Laser marking, meanwhile, is used for labeling and tracking battery components throughout the manufacturing process. This is important for quality control and traceability, as it allows manufacturers to monitor the production process and identify any issues that may arise. Overall, the integration of laser technologies in the production of solid-state batteries is a key factor in the advancement of this market. These technologies not only improve the quality and performance of the batteries but also enhance the efficiency and sustainability of the manufacturing process. As the demand for solid-state batteries continues to grow, the role of laser systems in their production will become increasingly important, driving further innovation and development in this field.

New Energy Vehicles, Consumer Electronics, Energy Storage Systems, Aerospace, Other in the Global Solid-state Battery Laser System Market:

The Global Solid-state Battery Laser System Market finds its applications across various sectors, including New Energy Vehicles, Consumer Electronics, Energy Storage Systems, Aerospace, and others. In the realm of New Energy Vehicles, solid-state batteries are seen as a game-changer due to their higher energy density and improved safety features compared to traditional lithium-ion batteries. The use of laser systems in the production of these batteries ensures that they meet the stringent quality and performance standards required by the automotive industry. Laser technologies enable the precise manufacturing of battery components, which is crucial for the efficient functioning and longevity of electric vehicles. In Consumer Electronics, the demand for smaller, more efficient, and longer-lasting batteries is ever-increasing. Solid-state batteries, with their compact size and high energy capacity, are ideal for powering the latest gadgets and devices. Laser systems play a vital role in the production of these batteries, allowing manufacturers to create intricate designs and structures that maximize the battery's performance while minimizing its size. This is particularly important in the consumer electronics industry, where space is often at a premium. Energy Storage Systems also benefit from the advancements in solid-state battery technology. As the world shifts towards renewable energy sources, the need for efficient and reliable energy storage solutions becomes more critical. Solid-state batteries offer a promising solution, with their ability to store large amounts of energy safely and efficiently. Laser systems are integral to the production of these batteries, ensuring that they are manufactured to the highest standards of quality and reliability. In the Aerospace sector, the demand for lightweight, high-performance batteries is paramount. Solid-state batteries, with their superior energy density and safety features, are well-suited to meet these demands. The use of laser technologies in their production ensures that these batteries are not only high-performing but also lightweight and durable, making them ideal for use in aircraft and other aerospace applications. Other sectors, such as medical devices and industrial equipment, also stand to benefit from the advancements in solid-state battery technology. The precision and efficiency offered by laser systems in the production of these batteries make them an attractive option for a wide range of applications. As the Global Solid-state Battery Laser System Market continues to grow, its impact on these various sectors will become increasingly significant, driving further innovation and development in the field of energy storage solutions.

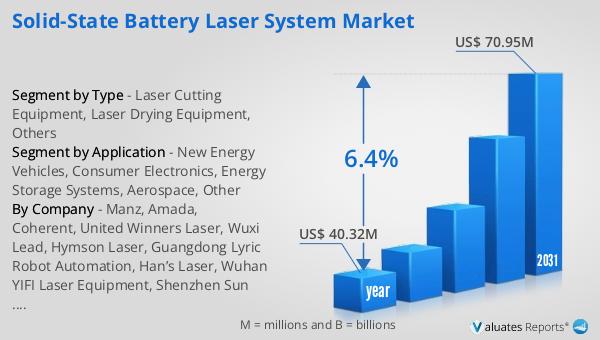

Global Solid-state Battery Laser System Market Outlook:

The worldwide market for Solid-state Battery Laser Systems was estimated to be worth $40.32 million in 2024. By 2031, it is anticipated to expand to a revised size of $70.95 million, reflecting a compound annual growth rate (CAGR) of 6.4% over the forecast period. This growth trajectory underscores the increasing demand and adoption of solid-state battery technologies across various industries. The market's expansion is driven by the need for more efficient, safer, and longer-lasting energy storage solutions, which solid-state batteries are well-positioned to provide. The integration of laser systems in the manufacturing process of these batteries is a key factor contributing to this growth. Laser technologies offer precision, efficiency, and cost-effectiveness, making them an essential component in the production of high-quality solid-state batteries. As industries such as electric vehicles, consumer electronics, and renewable energy storage continue to evolve, the demand for advanced battery technologies will only increase. This, in turn, will drive further innovation and development in the Global Solid-state Battery Laser System Market, solidifying its position as a critical player in the future of energy storage solutions. The projected growth of this market highlights the importance of continued investment in research and development to enhance the capabilities and applications of solid-state battery technologies.

| Report Metric | Details |

| Report Name | Solid-state Battery Laser System Market |

| Accounted market size in year | US$ 40.32 million |

| Forecasted market size in 2031 | US$ 70.95 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Manz, Amada, Coherent, United Winners Laser, Wuxi Lead, Hymson Laser, Guangdong Lyric Robot Automation, Han’s Laser, Wuhan YIFI Laser Equipment, Shenzhen Sun Laser Technology, Suzhou Delphi Laser, Shenzhen Yinghe Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |