What is Global Vertical Disc Filters Market?

The Global Vertical Disc Filters Market is a specialized segment within the filtration industry, focusing on the use of vertical disc filters for various applications. These filters are designed to separate solids from liquids in a highly efficient manner, making them essential in industries where liquid-solid separation is crucial. Vertical disc filters consist of a series of discs mounted on a vertical shaft, which rotates to facilitate the filtration process. The design allows for a compact footprint, making them suitable for installations with limited space. These filters are known for their high filtration efficiency, low energy consumption, and ease of maintenance. They are widely used in industries such as mineral processing, food and beverage, paper and pulp, pharmaceuticals, chemicals, and water treatment. The market for vertical disc filters is driven by the increasing demand for efficient and cost-effective filtration solutions across these industries. As environmental regulations become more stringent, the need for advanced filtration technologies that can meet compliance standards is also on the rise. This has led to continuous innovation and development in the vertical disc filters market, with manufacturers focusing on enhancing the performance and durability of their products to cater to the evolving needs of end-users.

Continuous Rotary Disc Filters, Batch-Type Rotary Disc Filters in the Global Vertical Disc Filters Market:

Continuous Rotary Disc Filters and Batch-Type Rotary Disc Filters are two prominent types of filters within the Global Vertical Disc Filters Market, each serving distinct purposes based on operational needs. Continuous Rotary Disc Filters are designed for processes that require uninterrupted filtration. They operate by rotating a series of discs continuously through a slurry, allowing for the constant separation of solids from liquids. This type of filter is particularly advantageous in industries where large volumes of slurry need to be processed without downtime, such as in mineral processing or large-scale chemical manufacturing. The continuous operation ensures a steady output, making it ideal for high-demand environments. These filters are engineered to handle varying slurry concentrations and can be customized to meet specific process requirements. On the other hand, Batch-Type Rotary Disc Filters are designed for processes that operate in discrete batches rather than continuously. These filters are suitable for applications where the filtration process can be paused between batches, allowing for maintenance or changes in the filtration setup. Batch-type filters are often used in industries where the production process is segmented into distinct phases, such as in certain pharmaceutical or specialty chemical applications. They offer flexibility in operation, allowing for adjustments in filtration parameters between batches to optimize performance. Both types of rotary disc filters share common advantages, such as high filtration efficiency and the ability to handle a wide range of slurry types. However, the choice between continuous and batch-type filters depends largely on the specific operational requirements of the industry and the nature of the materials being processed. Continuous Rotary Disc Filters are favored in scenarios where uninterrupted operation is critical, while Batch-Type Rotary Disc Filters are preferred in settings where process flexibility and adaptability are more important. The Global Vertical Disc Filters Market continues to evolve as industries seek more efficient and adaptable filtration solutions. Manufacturers are investing in research and development to enhance the capabilities of both continuous and batch-type filters, focusing on improving filtration rates, reducing energy consumption, and extending the lifespan of filter components. As industries face increasing pressure to optimize production processes and reduce environmental impact, the demand for advanced filtration technologies like rotary disc filters is expected to grow. This growth is driven by the need for reliable and efficient filtration systems that can meet the diverse and changing needs of various industrial applications.

Mineral Processing, Food Industry, Paper & Pulp, Pharmaceutical Industry, Chemical Industry, Water and Waste Water Treatment, Others in the Global Vertical Disc Filters Market:

The Global Vertical Disc Filters Market finds extensive usage across a variety of industries, each with unique requirements for liquid-solid separation. In mineral processing, vertical disc filters are crucial for dewatering mineral slurries, enhancing the recovery of valuable minerals while minimizing water usage. These filters help in achieving the desired moisture content in the final product, which is essential for efficient downstream processing. In the food industry, vertical disc filters are employed to clarify liquids, remove impurities, and ensure product quality. They are used in processes such as juice clarification, sugar refining, and edible oil purification, where maintaining the purity and quality of the final product is paramount. The paper and pulp industry relies on vertical disc filters for the dewatering of pulp and the recovery of fibers from process water. These filters help in reducing water consumption and improving the efficiency of the papermaking process. In the pharmaceutical industry, vertical disc filters are used for the filtration of active pharmaceutical ingredients (APIs) and other critical components, ensuring the purity and safety of pharmaceutical products. The chemical industry utilizes these filters for the separation of solids from liquid chemical mixtures, aiding in the production of high-purity chemicals and intermediates. Water and wastewater treatment facilities use vertical disc filters to remove suspended solids and impurities from water, contributing to the production of clean and safe water for various applications. Other industries, such as textiles and metallurgy, also benefit from the efficiency and reliability of vertical disc filters in their respective processes. The versatility and adaptability of vertical disc filters make them an indispensable tool across these diverse industries, driving their demand in the global market.

Global Vertical Disc Filters Market Outlook:

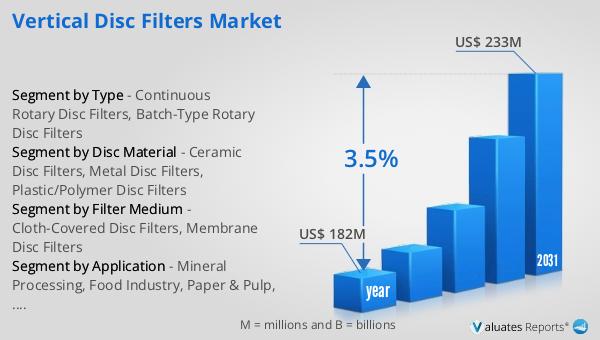

The global market for Vertical Disc Filters was valued at $182 million in 2024, with projections indicating a growth to $233 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.5% over the forecast period. The steady increase in market size reflects the rising demand for efficient filtration solutions across various industries. As industries continue to expand and evolve, the need for advanced filtration technologies that can meet stringent environmental and quality standards is becoming increasingly important. Vertical disc filters, with their high efficiency and adaptability, are well-positioned to meet these demands. The market growth is also driven by technological advancements in filter design and materials, which enhance the performance and durability of these filters. Additionally, the increasing focus on sustainability and resource optimization is encouraging industries to adopt filtration solutions that minimize waste and reduce energy consumption. As a result, the global vertical disc filters market is expected to continue its upward trajectory, supported by ongoing innovation and the growing need for reliable and efficient filtration systems. This positive market outlook underscores the importance of vertical disc filters in meeting the diverse and evolving needs of industries worldwide.

| Report Metric | Details |

| Report Name | Vertical Disc Filters Market |

| Accounted market size in year | US$ 182 million |

| Forecasted market size in 2031 | US$ 233 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Disc Material |

|

| Segment by Filter Medium |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Compositech Products Manufacturing, Clear Edge, Ant Group, Micronics (Cleanova), ANDRITZ, BOKELA (TSK), Gaudfrin, Peterson Filters Corporation, EIMCO-K.C.P., KHN Water Treatment Equipment, Wuxi Hengda Mining Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |