What is Global Oil Quality Detector Market?

The Global Oil Quality Detector Market is a specialized segment within the broader oil and gas industry, focusing on the development and deployment of devices that assess the quality of oil. These detectors are crucial for ensuring that oil used in various applications meets specific standards and is free from contaminants that could affect performance or safety. The market encompasses a range of technologies and devices designed to measure different parameters of oil quality, such as viscosity, density, and the presence of impurities. These detectors are used across various industries, including automotive, aerospace, and energy, to maintain the integrity and efficiency of machinery and processes. The demand for oil quality detectors is driven by the need for improved operational efficiency, regulatory compliance, and the prevention of equipment failure. As industries continue to rely heavily on oil for lubrication and energy, the importance of maintaining high-quality oil becomes paramount. This market is characterized by continuous innovation, with companies investing in research and development to create more accurate, reliable, and user-friendly detectors. The growth of this market is also supported by the increasing awareness of the environmental impact of oil usage and the need for sustainable practices.

Physical Parameter Sensor, Chemical Parameter Sensor in the Global Oil Quality Detector Market:

In the Global Oil Quality Detector Market, sensors play a pivotal role in determining the physical and chemical properties of oil. Physical Parameter Sensors are designed to measure attributes such as viscosity, density, and temperature. These sensors are essential for understanding how oil behaves under different conditions, which is crucial for applications where precise lubrication is necessary. For instance, in automotive engines, the viscosity of oil can affect fuel efficiency and engine performance. By using physical parameter sensors, operators can ensure that the oil maintains its optimal properties, thereby enhancing the longevity and efficiency of the machinery. These sensors often employ technologies like ultrasonic waves or thermal conductivity to provide accurate readings. On the other hand, Chemical Parameter Sensors focus on detecting the presence of contaminants or chemical changes in the oil. These sensors are vital for identifying issues such as oxidation, acid formation, or the presence of water and other impurities. In industries like aerospace, where the reliability of every component is critical, chemical parameter sensors help in maintaining the purity and effectiveness of lubricants. They often use techniques such as spectroscopy or electrochemical analysis to detect even minute changes in the oil's composition. The integration of these sensors into oil quality detectors allows for comprehensive monitoring, ensuring that both the physical and chemical integrity of the oil is maintained. This dual approach is particularly important in sectors where the failure of machinery due to poor oil quality can lead to significant financial losses or safety hazards. As technology advances, these sensors are becoming more sophisticated, offering real-time data and remote monitoring capabilities. This evolution is driven by the need for more efficient maintenance practices and the desire to minimize downtime. By providing detailed insights into the condition of the oil, these sensors enable proactive maintenance strategies, reducing the risk of unexpected failures. The development of smart sensors, which can communicate with central systems and provide alerts when oil quality deviates from acceptable parameters, is a significant trend in this market. These advancements not only improve the reliability of machinery but also contribute to cost savings by optimizing oil usage and extending the intervals between oil changes. As industries continue to prioritize efficiency and sustainability, the role of physical and chemical parameter sensors in the Global Oil Quality Detector Market will only become more critical.

Aerospace, Oil and Gas, Electricity, Others in the Global Oil Quality Detector Market:

The Global Oil Quality Detector Market finds its application across various sectors, each with unique requirements and challenges. In the aerospace industry, the reliability and performance of lubricants are of utmost importance. Aircraft engines and other critical components operate under extreme conditions, and any compromise in oil quality can lead to catastrophic failures. Oil quality detectors in this sector are used to monitor the condition of lubricants, ensuring they remain free from contaminants and maintain their protective properties. This not only enhances the safety and efficiency of aircraft but also helps in extending the service life of components, reducing maintenance costs, and preventing unscheduled downtime. In the oil and gas industry, the quality of oil is crucial for both upstream and downstream operations. Oil quality detectors are employed to assess the condition of crude oil, refined products, and lubricants used in machinery. By ensuring that the oil meets the required standards, these detectors help in optimizing production processes, improving equipment reliability, and minimizing environmental impact. In the electricity sector, oil is often used as a coolant and insulator in transformers and other electrical equipment. The quality of this oil is vital for the safe and efficient operation of the equipment. Oil quality detectors are used to monitor parameters such as moisture content, acidity, and dielectric strength, ensuring that the oil maintains its insulating properties and prevents equipment failures. Other industries, such as manufacturing and transportation, also rely on oil quality detectors to maintain the performance and longevity of their machinery. In these sectors, the detectors help in identifying issues such as wear and tear, contamination, and degradation of lubricants, enabling timely maintenance and reducing the risk of costly breakdowns. The versatility and importance of oil quality detectors across these diverse applications highlight their critical role in modern industrial operations. As industries continue to evolve and face new challenges, the demand for advanced oil quality detection solutions is expected to grow, driven by the need for improved efficiency, safety, and sustainability.

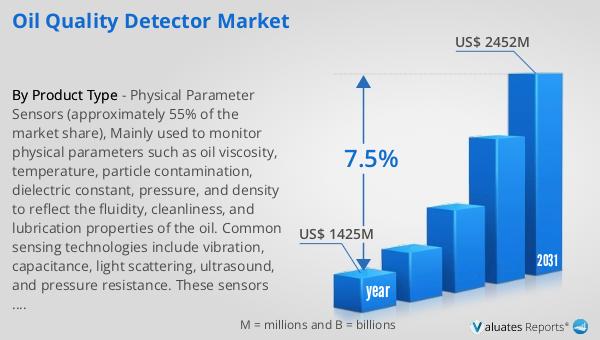

Global Oil Quality Detector Market Outlook:

The global market for Oil Quality Detectors was valued at approximately $1,425 million in 2024. It is anticipated to expand significantly, reaching an estimated size of $2,452 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.5% over the forecast period. This upward trend is indicative of the increasing importance placed on maintaining high standards of oil quality across various industries. As businesses strive to enhance operational efficiency and comply with stringent regulatory requirements, the demand for reliable and accurate oil quality detectors is on the rise. The market's expansion is also fueled by technological advancements that have led to the development of more sophisticated and user-friendly detection devices. These innovations enable industries to monitor oil quality in real-time, allowing for proactive maintenance and reducing the risk of equipment failure. Furthermore, the growing awareness of environmental sustainability and the need to minimize the ecological impact of oil usage are driving the adoption of oil quality detectors. By ensuring that oil is used efficiently and responsibly, these detectors contribute to the broader goals of reducing waste and promoting sustainable practices. As the market continues to grow, it is expected to play a pivotal role in supporting industries' efforts to achieve greater efficiency, safety, and environmental stewardship.

| Report Metric | Details |

| Report Name | Oil Quality Detector Market |

| Accounted market size in year | US$ 1425 million |

| Forecasted market size in 2031 | US$ 2452 million |

| CAGR | 7.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| By Product Type |

|

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Parker Hannifin, Pall Corporation, Emerson Electric, Kittiwake, SKF, General Electric (GE), Hydac, Moore Industries, Bently Nevada, Endress+Hauser, Buehler, Oerlikon Balzers, Mettler Toledo, Testo, Honeywell, Anton-paar, Senther |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |