What is Global Monolithic Refractory for Tundish Market?

Global Monolithic Refractory for Tundish Market refers to a specialized segment within the broader refractory industry, focusing on materials used in tundishes. Tundishes are essential components in the continuous casting process of steel manufacturing, acting as a reservoir that regulates the flow of molten metal from the ladle to the mold. The monolithic refractory materials used in tundishes are crucial for maintaining the integrity and efficiency of this process. These materials are designed to withstand extreme temperatures and corrosive environments, ensuring the smooth transfer of molten steel. The global market for these materials is driven by the demand for high-quality steel production, advancements in refractory technology, and the need for cost-effective and durable solutions. As industries continue to evolve, the importance of reliable and efficient refractory materials in tundishes becomes increasingly significant, making this market a vital component of the steel manufacturing sector. The market's growth is influenced by factors such as technological advancements, increasing steel production, and the need for sustainable and efficient manufacturing processes. As a result, the Global Monolithic Refractory for Tundish Market plays a crucial role in supporting the steel industry's continuous casting operations.

Castable Refractory, Plastic Material, Coating Material, Refractory Mortar, Other in the Global Monolithic Refractory for Tundish Market:

Castable refractory materials are a key component of the Global Monolithic Refractory for Tundish Market. These materials are known for their versatility and ease of installation, as they can be molded into various shapes and sizes to fit specific tundish designs. Castable refractories are composed of a mixture of refractory aggregates, binders, and additives, which are combined to create a material that can withstand high temperatures and corrosive environments. The primary advantage of castable refractories is their ability to be cast in place, allowing for seamless integration into existing tundish structures. This makes them an ideal choice for repairs and maintenance, as well as for new installations. Plastic refractory materials, on the other hand, are pre-mixed and ready-to-use, offering a convenient solution for tundish applications. These materials are pliable and can be easily shaped to fit the contours of the tundish, providing a tight seal and excellent thermal insulation. Plastic refractories are particularly useful in situations where rapid installation is required, as they can be applied quickly and efficiently. Coating materials are another important aspect of the Global Monolithic Refractory for Tundish Market. These materials are applied to the surface of the tundish to provide an additional layer of protection against thermal shock and chemical attack. Coatings are typically composed of refractory oxides and other additives, which enhance the performance and longevity of the tundish. Refractory mortar is used to bond refractory bricks and other components together, ensuring a strong and durable structure. This material is essential for maintaining the integrity of the tundish, as it prevents the infiltration of molten metal and other contaminants. Other materials used in the Global Monolithic Refractory for Tundish Market include gunning mixes, ramming mixes, and patching materials, each of which serves a specific purpose in the maintenance and repair of tundishes. Gunning mixes are applied using a pneumatic gun, allowing for quick and efficient repairs, while ramming mixes are used to fill gaps and voids in the tundish lining. Patching materials are used to repair small areas of damage, ensuring the continued performance of the tundish. Together, these materials form a comprehensive suite of solutions for the Global Monolithic Refractory for Tundish Market, providing the necessary protection and performance required for efficient steel production.

Steel, Cement, Ceramics, Glass, Nonferrous Metals, Others in the Global Monolithic Refractory for Tundish Market:

The Global Monolithic Refractory for Tundish Market finds its usage across various industries, each with unique requirements and challenges. In the steel industry, tundishes play a critical role in the continuous casting process, where molten steel is transferred from the ladle to the mold. The refractory materials used in tundishes must withstand extreme temperatures and corrosive environments, ensuring the smooth flow of molten steel and preventing contamination. This is crucial for producing high-quality steel products, as any impurities or inconsistencies can compromise the final product's integrity. In the cement industry, refractory materials are used to line kilns and other high-temperature equipment. The durability and thermal resistance of monolithic refractories make them ideal for these applications, as they can withstand the harsh conditions of cement production. Similarly, in the ceramics industry, refractory materials are used to line kilns and furnaces, where they provide the necessary insulation and protection against thermal shock. The glass industry also relies on refractory materials to line furnaces and other high-temperature equipment. The transparency and purity of glass products depend on the quality of the refractory materials used, as any impurities can affect the final product's appearance and performance. Nonferrous metals, such as aluminum and copper, require specialized refractory materials to withstand the unique challenges of their production processes. The Global Monolithic Refractory for Tundish Market provides the necessary solutions for these industries, ensuring efficient and reliable production. Other industries, such as petrochemicals and power generation, also benefit from the use of monolithic refractory materials, as they provide the necessary protection and performance required for high-temperature applications. Overall, the Global Monolithic Refractory for Tundish Market plays a vital role in supporting various industries, providing the necessary materials for efficient and reliable production processes.

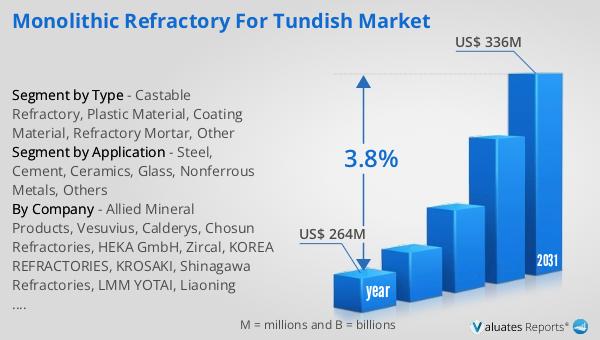

Global Monolithic Refractory for Tundish Market Outlook:

The worldwide market for Monolithic Refractory for Tundish was estimated to be worth $264 million in 2024. It is anticipated to grow to a revised size of $336 million by 2031, with a compound annual growth rate (CAGR) of 3.8% during the forecast period. This growth reflects the increasing demand for high-quality refractory materials in the steel industry and other sectors that rely on tundishes for their production processes. As industries continue to evolve and seek more efficient and sustainable manufacturing methods, the need for reliable and durable refractory materials becomes increasingly important. The projected growth of the Global Monolithic Refractory for Tundish Market highlights the significance of these materials in supporting the continuous casting process and ensuring the production of high-quality steel products. The market's expansion is driven by factors such as technological advancements, increasing steel production, and the need for cost-effective and durable solutions. As a result, the Global Monolithic Refractory for Tundish Market is expected to play a crucial role in supporting the steel industry's continuous casting operations and other high-temperature applications across various industries.

| Report Metric | Details |

| Report Name | Monolithic Refractory for Tundish Market |

| Accounted market size in year | US$ 264 million |

| Forecasted market size in 2031 | US$ 336 million |

| CAGR | 3.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Allied Mineral Products, Vesuvius, Calderys, Chosun Refractories, HEKA GmbH, Zircal, KOREA REFRACTORIES, KROSAKI, Shinagawa Refractories, LMM YOTAI, Liaoning Donghe New Materials, Puyang Refractories Group, Zhengzhou Rongsheng Refractory, Zhengzhou Huaxiang Refractories, Luoyang Kechuang New Materials, Henan Changxing Refractory Material, Jiaozuo Jinxin Hengtuo Advanced Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |