What is Global Molded Trays Market?

The Global Molded Trays Market refers to the industry focused on the production and distribution of molded trays, which are used for packaging and protecting various products. These trays are typically made from materials like plastic, pulp, or other biodegradable substances, and are designed to provide a secure and stable environment for items during transportation and storage. Molded trays are widely used across different sectors, including food and beverages, consumer goods, electronics, and industrial applications, due to their versatility and ability to be customized according to specific needs. The market is driven by the increasing demand for sustainable and eco-friendly packaging solutions, as well as the growing emphasis on reducing plastic waste. As businesses and consumers become more environmentally conscious, the demand for molded trays made from renewable and biodegradable materials is expected to rise. Additionally, advancements in manufacturing technologies have enabled the production of high-quality molded trays that offer enhanced durability and protection, further boosting their adoption across various industries. Overall, the Global Molded Trays Market is poised for significant growth as it continues to evolve and adapt to the changing needs of consumers and businesses worldwide.

Renewable Pulp, Virgin Pulp in the Global Molded Trays Market:

Renewable pulp and virgin pulp are two key materials used in the production of molded trays, each offering distinct advantages and characteristics that cater to different market needs. Renewable pulp is derived from recycled paper and cardboard, making it an environmentally friendly option that aligns with the growing demand for sustainable packaging solutions. This type of pulp is processed to remove impurities and is then molded into trays that are biodegradable and compostable. The use of renewable pulp in molded trays is particularly appealing to businesses and consumers who prioritize reducing their carbon footprint and minimizing waste. On the other hand, virgin pulp is made from fresh wood fibers, offering superior strength and durability compared to renewable pulp. Virgin pulp is often used in applications where the packaging needs to withstand more rigorous handling or provide a higher level of protection for the contents. While virgin pulp is not as eco-friendly as renewable pulp, it is still a popular choice in the molded trays market due to its reliability and performance. The decision between using renewable pulp or virgin pulp in molded trays often depends on the specific requirements of the product being packaged, as well as the environmental goals of the company. In recent years, there has been a noticeable shift towards using renewable pulp in molded trays, driven by consumer demand for sustainable products and stricter regulations on plastic use. Companies are increasingly investing in research and development to improve the quality and performance of renewable pulp trays, making them more competitive with their virgin pulp counterparts. This shift is also supported by advancements in recycling technologies, which have made it easier and more cost-effective to produce high-quality renewable pulp. Despite the growing popularity of renewable pulp, virgin pulp remains an important material in the molded trays market, particularly for applications that require enhanced strength and durability. The choice between renewable and virgin pulp is often influenced by factors such as cost, availability, and the specific needs of the end-user. As the market continues to evolve, it is likely that both renewable and virgin pulp will play important roles in meeting the diverse demands of consumers and businesses. The ongoing development of new materials and technologies will further expand the possibilities for molded trays, offering even more options for sustainable and effective packaging solutions. In conclusion, the Global Molded Trays Market is characterized by the use of both renewable and virgin pulp, each offering unique benefits that cater to different needs. As the industry continues to grow and adapt to changing consumer preferences and environmental regulations, the demand for molded trays made from sustainable materials is expected to increase. Companies that can effectively balance the use of renewable and virgin pulp in their products will be well-positioned to succeed in this dynamic and evolving market.

Food and Beverages, Consumer Goods, Machinery Parts, Other in the Global Molded Trays Market:

The Global Molded Trays Market finds extensive usage across various sectors, including food and beverages, consumer goods, machinery parts, and other industries, due to its versatility and ability to provide effective packaging solutions. In the food and beverages sector, molded trays are commonly used for packaging fresh produce, baked goods, ready-to-eat meals, and beverages. These trays help maintain the freshness and quality of the food products by providing a secure and stable environment during transportation and storage. Additionally, molded trays made from biodegradable materials are increasingly preferred in this sector, as they align with the growing demand for sustainable and eco-friendly packaging solutions. In the consumer goods industry, molded trays are used for packaging a wide range of products, including electronics, cosmetics, and personal care items. The trays provide protection against damage during shipping and handling, ensuring that the products reach consumers in perfect condition. Molded trays can be customized to fit the specific dimensions and shapes of the products, offering a tailored packaging solution that enhances the overall presentation and appeal of the goods. In the machinery parts sector, molded trays are used to package and protect various components and parts during transportation and storage. These trays offer a secure and organized way to store and transport machinery parts, reducing the risk of damage and ensuring that the parts remain in optimal condition. Molded trays made from durable materials are particularly important in this sector, as they need to withstand the rigors of handling and transportation. In addition to these sectors, molded trays are also used in other industries, such as pharmaceuticals, automotive, and agriculture. In the pharmaceutical industry, molded trays are used to package and protect delicate medical devices and equipment, ensuring that they remain sterile and free from contamination. In the automotive industry, molded trays are used to package and transport various components and parts, providing a secure and organized way to store and transport these items. In the agriculture sector, molded trays are used for packaging and transporting seedlings and plants, providing a stable and secure environment for the plants to grow and thrive. Overall, the Global Molded Trays Market is characterized by its wide range of applications across various industries, each with its own unique requirements and demands. The versatility and adaptability of molded trays make them an ideal packaging solution for a diverse range of products, from food and beverages to machinery parts and beyond. As the market continues to evolve and adapt to changing consumer preferences and environmental regulations, the demand for molded trays is expected to increase, driven by the need for sustainable and effective packaging solutions.

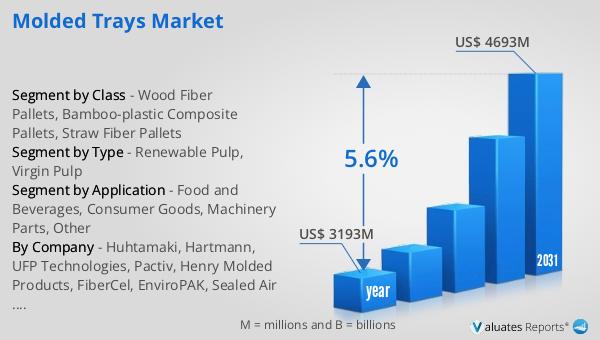

Global Molded Trays Market Outlook:

In 2024, the global market for molded trays was valued at approximately $3,193 million. This market is anticipated to grow significantly over the coming years, reaching an estimated value of $4,693 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.6% throughout the forecast period. The increasing demand for molded trays can be attributed to several factors, including the rising need for sustainable packaging solutions and the growing emphasis on reducing plastic waste. As businesses and consumers become more environmentally conscious, the demand for molded trays made from renewable and biodegradable materials is expected to rise. Additionally, advancements in manufacturing technologies have enabled the production of high-quality molded trays that offer enhanced durability and protection, further boosting their adoption across various industries. The market's expansion is also driven by the increasing use of molded trays in sectors such as food and beverages, consumer goods, and machinery parts, where they provide effective packaging solutions that help maintain the quality and integrity of the products. As the market continues to evolve and adapt to changing consumer preferences and environmental regulations, the demand for molded trays is expected to increase, driven by the need for sustainable and effective packaging solutions.

| Report Metric | Details |

| Report Name | Molded Trays Market |

| Accounted market size in year | US$ 3193 million |

| Forecasted market size in 2031 | US$ 4693 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Class |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Huhtamaki, Hartmann, UFP Technologies, Pactiv, Henry Molded Products, FiberCel, EnviroPAK, Sealed Air (AFP), KEYES Packaging Group, Western Pulp, CDL Omni-Pac, TRIDAS Ltd, Cemosa, Okulovskaya Paper Factory, Cullen, Buhl Paperform GmbH, Dentas Paper Industry, DFM Packaging Solutions, Nippon Molding, Paishing Technology, Lihua Group, KINYI Technology, Qingdao Haigerui New Materials Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |