What is Global Laser Quenching Machine Market?

The Global Laser Quenching Machine Market refers to the industry focused on the production and sale of machines that use laser technology to harden the surface of metal components. This process, known as laser quenching, involves rapidly heating a metal surface with a laser beam and then cooling it quickly to increase its hardness and wear resistance. The market for these machines is driven by the demand for durable and high-performance metal parts in various industries, such as automotive, aerospace, and manufacturing. Laser quenching offers several advantages over traditional hardening methods, including precision, efficiency, and the ability to treat complex shapes without causing distortion. As industries continue to seek ways to enhance the performance and longevity of their products, the demand for laser quenching machines is expected to grow. This market encompasses a range of machine types, from fully automated systems to semi-automatic models, catering to different industrial needs and scales of operation. The global reach of this market highlights its importance in modern manufacturing processes, where precision and durability are paramount.

Fully Automatic, Semi-automatic in the Global Laser Quenching Machine Market:

In the Global Laser Quenching Machine Market, machines are typically categorized into two main types: fully automatic and semi-automatic. Fully automatic laser quenching machines are designed to operate with minimal human intervention, offering high precision and efficiency. These machines are equipped with advanced software and sensors that allow them to perform complex tasks with accuracy. They are ideal for large-scale manufacturing operations where consistency and speed are crucial. The automation in these machines reduces the likelihood of human error, ensuring that each component is treated uniformly. This is particularly beneficial in industries like automotive and aerospace, where even minor deviations can lead to significant issues. On the other hand, semi-automatic laser quenching machines require some level of human involvement. While they still offer a high degree of precision, operators are needed to oversee the process and make adjustments as necessary. These machines are often more flexible than their fully automatic counterparts, allowing for customization and adaptation to different tasks. They are suitable for smaller operations or for companies that require a more hands-on approach to production. The choice between fully automatic and semi-automatic machines depends largely on the specific needs of the business, including the volume of production, the complexity of the components being treated, and the level of precision required. Both types of machines play a crucial role in the market, providing solutions for a wide range of industrial applications. As technology continues to advance, the capabilities of both fully automatic and semi-automatic laser quenching machines are expected to improve, offering even greater efficiency and precision. This evolution will likely lead to increased adoption across various industries, further driving the growth of the Global Laser Quenching Machine Market.

Automobiles, Machinery Manufacturing, Energy, Aerospace, Other in the Global Laser Quenching Machine Market:

The Global Laser Quenching Machine Market finds its applications across several key industries, each benefiting from the unique advantages offered by laser quenching technology. In the automotive industry, laser quenching machines are used to enhance the durability and performance of critical components such as gears, camshafts, and crankshafts. The precision and efficiency of laser quenching ensure that these parts can withstand the high stresses and wear they encounter during operation, thereby extending the lifespan of vehicles and reducing maintenance costs. In machinery manufacturing, laser quenching is employed to improve the hardness and wear resistance of machine parts, leading to more reliable and long-lasting equipment. This is particularly important in heavy machinery and industrial equipment, where component failure can result in costly downtime and repairs. The energy sector also benefits from laser quenching technology, particularly in the production of components for power generation and transmission. By enhancing the durability of these parts, laser quenching helps to ensure the reliability and efficiency of energy systems. In the aerospace industry, where safety and performance are paramount, laser quenching is used to treat critical components such as turbine blades and landing gear. The ability to precisely control the hardening process allows manufacturers to produce parts that meet the stringent requirements of the aerospace sector. Additionally, laser quenching is used in other industries, such as defense and medical device manufacturing, where the need for high-performance, durable components is essential. The versatility and effectiveness of laser quenching machines make them a valuable tool in a wide range of applications, driving their adoption across multiple sectors. As industries continue to seek ways to improve the performance and longevity of their products, the demand for laser quenching machines is expected to grow, further solidifying their role in modern manufacturing processes.

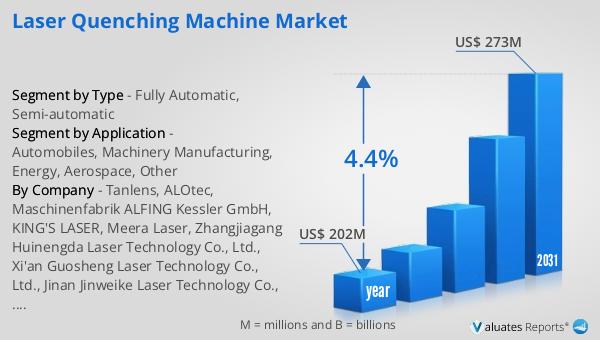

Global Laser Quenching Machine Market Outlook:

The outlook for the Global Laser Quenching Machine Market indicates a positive growth trajectory over the coming years. In 2024, the market was valued at approximately US$ 202 million. By 2031, it is anticipated to reach a revised size of around US$ 273 million. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.4% during the forecast period. This upward trend reflects the increasing demand for laser quenching machines across various industries, driven by the need for durable and high-performance metal components. The precision and efficiency offered by laser quenching technology make it an attractive option for manufacturers looking to enhance the quality and longevity of their products. As industries continue to evolve and seek innovative solutions to improve their manufacturing processes, the adoption of laser quenching machines is likely to increase. This growth is further supported by advancements in technology, which are expected to enhance the capabilities of these machines, making them even more efficient and versatile. The expanding applications of laser quenching across different sectors, including automotive, aerospace, and energy, also contribute to the positive market outlook. As the global economy continues to recover and industrial activities pick up pace, the demand for laser quenching machines is expected to rise, driving the market's growth in the coming years.

| Report Metric | Details |

| Report Name | Laser Quenching Machine Market |

| Accounted market size in year | US$ 202 million |

| Forecasted market size in 2031 | US$ 273 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tanlens, ALOtec, Maschinenfabrik ALFING Kessler GmbH, KING'S LASER, Meera Laser, Zhangjiagang Huinengda Laser Technology Co., Ltd., Xi'an Guosheng Laser Technology Co., Ltd., Jinan Jinweike Laser Technology Co., Ltd., Jiangsu Yawei Machine Tool Co., Ltd., Ningbo Haitian Laser Machinery Manufacturing Co., Ltd., Greenstone-Tech, HUIRUI group, Scantech Laser |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |