What is Global Industrial Metal Heating Element Market?

The Global Industrial Metal Heating Element Market is a dynamic and essential segment within the broader industrial sector. These heating elements are crucial components used in various industrial applications to generate heat through electrical resistance. They are typically made from metal alloys that can withstand high temperatures and are designed to convert electrical energy into heat efficiently. The market for these elements is driven by the increasing demand for energy-efficient heating solutions across various industries, including manufacturing, chemical processing, and electronics. As industries continue to seek ways to improve energy efficiency and reduce operational costs, the demand for advanced heating elements is expected to grow. These elements are integral to processes that require precise temperature control and consistent heat distribution, making them indispensable in modern industrial operations. The market is characterized by continuous innovation, with manufacturers focusing on developing elements that offer higher performance, longer lifespan, and greater energy efficiency. This market's growth is also supported by the expansion of industries in emerging economies, where industrialization is rapidly increasing. Overall, the Global Industrial Metal Heating Element Market plays a vital role in supporting industrial processes worldwide, contributing to enhanced productivity and efficiency.

Nickel-Chromium Alloy Wire, Fe-Chromium-Aluminum Alloy Wire, Other in the Global Industrial Metal Heating Element Market:

Nickel-Chromium Alloy Wire, Fe-Chromium-Aluminum Alloy Wire, and other materials are pivotal in the Global Industrial Metal Heating Element Market, each offering unique properties that cater to specific industrial needs. Nickel-Chromium Alloy Wire, often referred to as Nichrome, is a popular choice due to its excellent resistance to oxidation and high-temperature stability. This alloy is composed primarily of nickel and chromium, which together provide a robust and durable heating element capable of withstanding extreme temperatures without degrading. Nichrome is widely used in applications requiring consistent and reliable heat, such as in electric ovens, toasters, and industrial furnaces. Its ability to maintain structural integrity at high temperatures makes it ideal for environments where precise temperature control is crucial. On the other hand, Fe-Chromium-Aluminum Alloy Wire, commonly known as Kanthal, is another widely used material in the heating element market. This alloy is composed of iron, chromium, and aluminum, offering excellent resistance to oxidation and high-temperature corrosion. Kanthal is known for its high resistivity and low density, which contribute to its energy efficiency and longevity. It is often used in applications where high power density and rapid heating are required, such as in kilns, ceramic heaters, and glass processing equipment. The unique properties of Kanthal make it suitable for environments where rapid temperature changes occur, as it can quickly adapt to varying thermal conditions without compromising performance. In addition to these two primary alloys, other materials are also used in the production of industrial metal heating elements. These include copper-nickel alloys, stainless steel, and various specialty alloys designed for specific applications. Copper-nickel alloys, for example, are known for their excellent thermal conductivity and are often used in applications where efficient heat transfer is essential. Stainless steel, with its corrosion resistance and durability, is used in environments where exposure to moisture or corrosive substances is a concern. Specialty alloys are developed to meet the unique demands of specific industries, offering tailored solutions that enhance performance and efficiency. The choice of material for a heating element depends on several factors, including the operating temperature, environment, and specific application requirements. Manufacturers in the Global Industrial Metal Heating Element Market continuously innovate to develop materials that offer improved performance, energy efficiency, and longevity. This focus on innovation ensures that the market remains dynamic and responsive to the evolving needs of various industries. As industries continue to prioritize energy efficiency and sustainability, the demand for advanced heating elements made from high-performance materials is expected to grow. This growth is further supported by the increasing adoption of automation and advanced manufacturing technologies, which require precise and reliable heating solutions. Overall, the diverse range of materials used in the Global Industrial Metal Heating Element Market highlights the importance of selecting the right material for each application, ensuring optimal performance and efficiency.

Plastic Machinery Heating, Chemical/Petrochemical Heating, Metallurgical/Glass/Ceramic Kilns, Food and Pharmaceutical Drying Equipment, Other in the Global Industrial Metal Heating Element Market:

The Global Industrial Metal Heating Element Market finds extensive usage across various industries, each with unique requirements for heating solutions. In the realm of plastic machinery heating, these elements are crucial for processes such as injection molding, extrusion, and thermoforming. Precise temperature control is essential in these applications to ensure the quality and consistency of plastic products. Industrial metal heating elements provide the necessary heat to melt and mold plastic materials, enabling manufacturers to produce a wide range of plastic products efficiently. The ability to maintain consistent temperatures is vital in preventing defects and ensuring the structural integrity of plastic components. In the chemical and petrochemical industries, heating elements play a critical role in processes such as distillation, evaporation, and chemical synthesis. These processes often require high temperatures and precise control to facilitate chemical reactions and separate components. Industrial metal heating elements are used in reactors, heat exchangers, and other equipment to provide the necessary heat for these processes. Their durability and resistance to corrosion make them ideal for use in harsh chemical environments, where exposure to corrosive substances is common. In metallurgical, glass, and ceramic kilns, heating elements are essential for achieving the high temperatures required for melting and shaping materials. These industries rely on industrial metal heating elements to provide consistent and reliable heat, ensuring the quality and uniformity of the final products. The ability to withstand extreme temperatures and maintain performance over extended periods is crucial in these applications, where precision and consistency are paramount. In the food and pharmaceutical industries, drying equipment equipped with industrial metal heating elements is used to remove moisture from products, ensuring their stability and shelf life. These elements provide the necessary heat to evaporate moisture without compromising the quality of the products. In pharmaceutical applications, precise temperature control is essential to prevent degradation of sensitive compounds and ensure the efficacy of medications. The versatility of industrial metal heating elements allows them to be used in a wide range of drying applications, from food processing to pharmaceutical manufacturing. Beyond these specific applications, industrial metal heating elements are used in various other industries, including electronics, automotive, and aerospace. In electronics manufacturing, they are used in soldering and reflow processes, where precise temperature control is essential for ensuring the quality of electronic components. In the automotive industry, heating elements are used in applications such as engine block heaters and seat warmers, providing comfort and functionality to vehicles. In aerospace, they are used in de-icing systems and other critical applications where reliable heat is required. Overall, the Global Industrial Metal Heating Element Market serves a diverse range of industries, each with unique requirements for heating solutions. The ability to provide precise and reliable heat makes these elements indispensable in modern industrial processes, contributing to enhanced productivity and efficiency across various sectors.

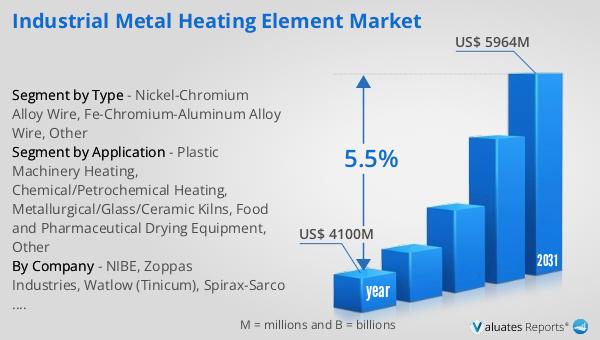

Global Industrial Metal Heating Element Market Outlook:

The global market for Industrial Metal Heating Elements was valued at $4.1 billion in 2024, and it is anticipated to grow significantly, reaching an estimated $5.964 billion by 2031. This growth represents a compound annual growth rate (CAGR) of 5.5% over the forecast period. The increasing demand for energy-efficient heating solutions across various industries is a key driver of this market expansion. As industries continue to seek ways to improve energy efficiency and reduce operational costs, the demand for advanced heating elements is expected to grow. These elements are integral to processes that require precise temperature control and consistent heat distribution, making them indispensable in modern industrial operations. The market is characterized by continuous innovation, with manufacturers focusing on developing elements that offer higher performance, longer lifespan, and greater energy efficiency. This market's growth is also supported by the expansion of industries in emerging economies, where industrialization is rapidly increasing. Overall, the Global Industrial Metal Heating Element Market plays a vital role in supporting industrial processes worldwide, contributing to enhanced productivity and efficiency.

| Report Metric | Details |

| Report Name | Industrial Metal Heating Element Market |

| Accounted market size in year | US$ 4100 million |

| Forecasted market size in 2031 | US$ 5964 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NIBE, Zoppas Industries, Watlow (Tinicum), Spirax-Sarco Engineering plc, Thermon, Thermowatt (Ariston Thermo), Tempco Electric Heater Corporation, Hotset GmbH, Durex Industries, Tutco, Indeeco, Holroyd Components Ltd, Friedr. Freek GmbH, Minco Products, Inc., Industrial Heater Corporation, OMEGA(Spectris plc), Wattco, Thermal Corporation, EFD Induction |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |