What is Global High-purity Fused Silica for Thermal Processing Market?

The Global High-purity Fused Silica for Thermal Processing Market is a specialized segment within the broader materials industry, focusing on the production and application of high-purity fused silica. This material is renowned for its exceptional thermal stability, low thermal expansion, and high resistance to thermal shock, making it indispensable in various high-temperature processing applications. High-purity fused silica is derived from silica sand or quartz, which undergoes a purification process to remove impurities, resulting in a material with superior optical and thermal properties. The demand for this material is driven by its critical role in industries such as semiconductors, photovoltaics, and fiber optics, where precision and reliability are paramount. As technology advances and industries seek materials that can withstand extreme conditions, the market for high-purity fused silica continues to grow, offering opportunities for innovation and development in thermal processing applications. The market's expansion is also fueled by the increasing need for energy-efficient and sustainable solutions, as high-purity fused silica contributes to reducing energy consumption and enhancing the performance of thermal processing systems. Overall, the Global High-purity Fused Silica for Thermal Processing Market is poised for significant growth, driven by technological advancements and the ever-evolving demands of modern industries.

Synthetic Fused Quartz, Natural Fused Quartz in the Global High-purity Fused Silica for Thermal Processing Market:

Synthetic Fused Quartz and Natural Fused Quartz are two primary types of high-purity fused silica used in thermal processing applications. Synthetic Fused Quartz is produced through a chemical vapor deposition process, where silicon tetrachloride is reacted with oxygen to form silica. This method results in a highly pure material with minimal impurities, making it ideal for applications requiring exceptional optical clarity and thermal stability. Synthetic Fused Quartz is often used in the semiconductor industry, where precision and purity are critical for manufacturing processes. Its high resistance to thermal shock and low thermal expansion make it suitable for use in high-temperature environments, such as in the production of silicon wafers and other semiconductor components. On the other hand, Natural Fused Quartz is derived from naturally occurring quartz crystals, which are melted and purified to produce a material with similar properties to synthetic fused quartz. While it may contain slightly higher levels of impurities compared to its synthetic counterpart, natural fused quartz is still highly valued for its excellent thermal and optical properties. It is commonly used in applications where cost considerations are important, as it is generally less expensive to produce than synthetic fused quartz. In the Global High-purity Fused Silica for Thermal Processing Market, both synthetic and natural fused quartz play crucial roles, catering to different needs and preferences of industries. The choice between synthetic and natural fused quartz often depends on the specific requirements of the application, such as the desired level of purity, thermal stability, and cost-effectiveness. As industries continue to evolve and demand more advanced materials for thermal processing, the market for both synthetic and natural fused quartz is expected to grow, driven by the need for high-performance materials that can withstand extreme conditions. The versatility and reliability of these materials make them indispensable in a wide range of applications, from semiconductors and photovoltaics to fiber optics and aerospace. As a result, manufacturers and suppliers in the Global High-purity Fused Silica for Thermal Processing Market are continually exploring new ways to enhance the properties and performance of synthetic and natural fused quartz, ensuring they meet the ever-changing demands of modern industries.

Semiconductors, Photovoltaics, Fiber Optic Communications, Aerospace, Other in the Global High-purity Fused Silica for Thermal Processing Market:

The Global High-purity Fused Silica for Thermal Processing Market finds extensive usage across various industries, including semiconductors, photovoltaics, fiber optic communications, aerospace, and others. In the semiconductor industry, high-purity fused silica is essential for the production of silicon wafers, which are the foundation of electronic devices. Its exceptional thermal stability and low thermal expansion make it ideal for use in high-temperature processes, ensuring the precision and reliability required in semiconductor manufacturing. In photovoltaics, high-purity fused silica is used in the production of solar panels, where its optical clarity and thermal resistance contribute to the efficiency and durability of photovoltaic cells. The material's ability to withstand extreme temperatures and harsh environmental conditions makes it a preferred choice for solar energy applications. In fiber optic communications, high-purity fused silica is used to produce optical fibers, which are critical for high-speed data transmission. Its low attenuation and high transparency ensure the efficient transmission of light signals over long distances, making it indispensable in modern communication networks. In the aerospace industry, high-purity fused silica is used in the production of components that require high thermal resistance and lightweight properties, such as heat shields and insulation materials. Its ability to withstand extreme temperatures and thermal shock makes it ideal for use in aerospace applications, where performance and reliability are paramount. Beyond these industries, high-purity fused silica is also used in various other applications, such as in the production of laboratory equipment, lighting, and optics. Its versatility and exceptional properties make it a valuable material in a wide range of thermal processing applications, driving the growth of the Global High-purity Fused Silica for Thermal Processing Market. As industries continue to seek materials that offer superior performance and sustainability, the demand for high-purity fused silica is expected to increase, further fueling the market's expansion.

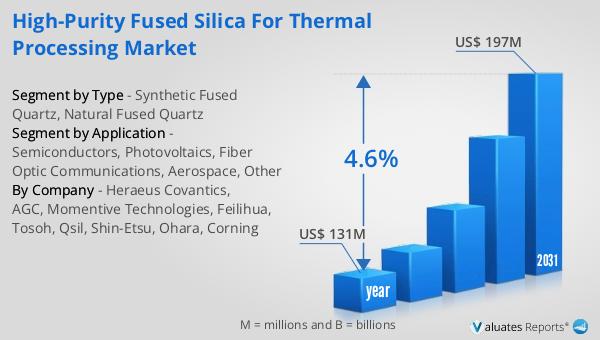

Global High-purity Fused Silica for Thermal Processing Market Outlook:

The global market for High-purity Fused Silica for Thermal Processing was valued at $131 million in 2024, with projections indicating a growth to $197 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.6% over the forecast period. This upward trend is indicative of the increasing demand for high-performance materials in various industries, driven by technological advancements and the need for energy-efficient solutions. The market's expansion is fueled by the growing adoption of high-purity fused silica in critical applications such as semiconductors, photovoltaics, and fiber optics, where precision and reliability are essential. As industries continue to evolve and seek materials that can withstand extreme conditions, the demand for high-purity fused silica is expected to rise, further driving the market's growth. The projected increase in market size reflects the ongoing efforts of manufacturers and suppliers to enhance the properties and performance of high-purity fused silica, ensuring it meets the ever-changing demands of modern industries. As a result, the Global High-purity Fused Silica for Thermal Processing Market is poised for significant growth, offering opportunities for innovation and development in thermal processing applications.

| Report Metric | Details |

| Report Name | High-purity Fused Silica for Thermal Processing Market |

| Accounted market size in year | US$ 131 million |

| Forecasted market size in 2031 | US$ 197 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Heraeus Covantics, AGC, Momentive Technologies, Feilihua, Tosoh, Qsil, Shin-Etsu, Ohara, Corning |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |