What is Global Disc Continuous Drying Machine Market?

The Global Disc Continuous Drying Machine Market is a specialized segment within the industrial machinery sector, focusing on machines designed to efficiently dry materials in a continuous process. These machines are particularly valued for their ability to handle large volumes of material with consistent quality and efficiency. The disc continuous drying machine operates by using a series of rotating discs that facilitate the drying process, ensuring that materials are evenly exposed to heat and airflow. This method is advantageous because it reduces drying time and energy consumption compared to traditional batch drying methods. The market for these machines is driven by industries that require precise and efficient drying solutions, such as chemicals, pharmaceuticals, food processing, and feed production. As industries continue to seek ways to optimize their production processes and reduce operational costs, the demand for advanced drying technologies like disc continuous drying machines is expected to grow. These machines not only improve productivity but also contribute to sustainability by minimizing energy usage and waste. The global market for these machines is characterized by technological advancements, increasing automation, and a focus on energy efficiency, making it a dynamic and evolving sector.

Normal Pressure Sealed Type, Vacuum Type in the Global Disc Continuous Drying Machine Market:

In the Global Disc Continuous Drying Machine Market, two prominent types of machines are the Normal Pressure Sealed Type and the Vacuum Type. The Normal Pressure Sealed Type operates under atmospheric pressure and is designed to handle materials that do not require a vacuum environment for drying. This type is commonly used in applications where the material's properties are stable under normal atmospheric conditions. The sealed design ensures that the drying process is contained, minimizing the risk of contamination and ensuring consistent drying results. These machines are often equipped with advanced control systems that allow operators to precisely manage temperature and airflow, optimizing the drying process for different materials. On the other hand, the Vacuum Type disc continuous drying machine operates under reduced pressure, which lowers the boiling point of the liquid in the material, allowing it to evaporate at lower temperatures. This is particularly beneficial for heat-sensitive materials that might degrade or lose quality at higher temperatures. The vacuum environment also helps in preserving the material's color, flavor, and nutritional value, making it ideal for applications in the food and pharmaceutical industries. Vacuum Type machines are typically more complex and require more sophisticated control systems to maintain the vacuum environment and ensure efficient drying. Both types of machines are designed to be highly efficient, with features such as automated feeding and discharge systems, energy recovery systems, and advanced monitoring and control technologies. These features not only enhance the drying process but also contribute to reducing energy consumption and operational costs. The choice between Normal Pressure Sealed Type and Vacuum Type machines depends on the specific requirements of the application, including the nature of the material to be dried, the desired drying rate, and the quality standards that need to be met. As industries continue to evolve and demand more efficient and sustainable drying solutions, manufacturers of disc continuous drying machines are investing in research and development to enhance the performance and capabilities of both Normal Pressure Sealed Type and Vacuum Type machines. This includes the integration of smart technologies, such as IoT and AI, to enable real-time monitoring and optimization of the drying process. By leveraging these technologies, manufacturers aim to provide solutions that not only meet the current needs of the market but also anticipate future demands for more efficient, reliable, and environmentally friendly drying solutions.

Chemicals, Pharmaceuticals, Food, Feed, Other in the Global Disc Continuous Drying Machine Market:

The Global Disc Continuous Drying Machine Market finds extensive usage across various industries, including chemicals, pharmaceuticals, food, feed, and others, due to its efficiency and versatility. In the chemical industry, these machines are used to dry a wide range of chemical compounds, ensuring that they meet the required moisture content for further processing or packaging. The precise control over temperature and airflow allows for the drying of sensitive chemical materials without compromising their integrity or quality. In the pharmaceutical industry, disc continuous drying machines are essential for drying active pharmaceutical ingredients (APIs) and other compounds. The ability to operate under vacuum conditions is particularly beneficial for preserving the potency and efficacy of heat-sensitive pharmaceutical products. These machines ensure that the drying process is consistent and meets the stringent quality standards required in pharmaceutical manufacturing. In the food industry, disc continuous drying machines are used to dry various food products, including fruits, vegetables, grains, and spices. The vacuum drying option is especially useful for preserving the nutritional value, flavor, and color of food products, which is crucial for maintaining their quality and appeal to consumers. The feed industry also benefits from the use of disc continuous drying machines, as they are used to dry animal feed ingredients, ensuring that they have the appropriate moisture content for storage and consumption. This helps in preventing spoilage and maintaining the nutritional quality of the feed. Other industries, such as textiles and ceramics, also utilize these machines for drying purposes, taking advantage of their efficiency and ability to handle large volumes of material. The versatility of disc continuous drying machines makes them an invaluable asset across various sectors, as they provide reliable and efficient drying solutions that meet the diverse needs of different industries. As industries continue to prioritize efficiency, quality, and sustainability, the demand for advanced drying technologies like disc continuous drying machines is expected to grow, driving innovation and development in this market.

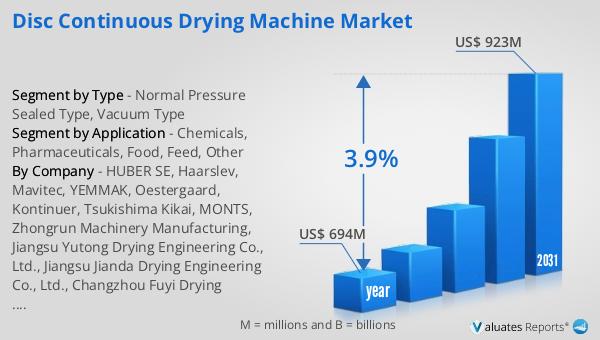

Global Disc Continuous Drying Machine Market Outlook:

The global market for Disc Continuous Drying Machines was valued at approximately $694 million in 2024. It is anticipated to expand to a revised size of around $923 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.9% over the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable drying solutions across various industries. The market's expansion is driven by the need for advanced drying technologies that can enhance productivity, reduce energy consumption, and improve product quality. As industries such as chemicals, pharmaceuticals, food, and feed continue to evolve, the demand for disc continuous drying machines is expected to rise, as these machines offer significant advantages in terms of efficiency and sustainability. The projected growth in the market also highlights the ongoing advancements in technology and automation, which are enabling manufacturers to develop more sophisticated and efficient drying solutions. As a result, the Global Disc Continuous Drying Machine Market is poised for continued growth and innovation, as it adapts to the changing needs and demands of various industries.

| Report Metric | Details |

| Report Name | Disc Continuous Drying Machine Market |

| Accounted market size in year | US$ 694 million |

| Forecasted market size in 2031 | US$ 923 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HUBER SE, Haarslev, Mavitec, YEMMAK, Oestergaard, Kontinuer, Tsukishima Kikai, MONTS, Zhongrun Machinery Manufacturing, Jiangsu Yutong Drying Engineering Co., Ltd., Jiangsu Jianda Drying Engineering Co., Ltd., Changzhou Fuyi Drying Equipment Co., Ltd., Aerbeishi Electric Motor Technology (Shanghai) Co., Ltd., Shandong ChemSta Machinery Manufacturing Co.,LTD., Changzhou Kemao Drying Equipment Co., Ltd., Changzhou Yiqiu Zhongya Drying Equipment Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |