What is Global Cubic Nd:YAG Crystal Market?

The Global Cubic Nd:YAG Crystal Market is a specialized segment within the broader laser crystal industry, focusing on the production and application of cubic neodymium-doped yttrium aluminum garnet (Nd:YAG) crystals. These crystals are renowned for their exceptional optical properties, making them a preferred choice in various laser applications. Nd:YAG crystals are primarily used in solid-state lasers, where they serve as the gain medium. The cubic form of Nd:YAG is particularly valued for its isotropic properties, which means it has uniform characteristics in all directions, enhancing its performance in laser systems. This market is driven by the increasing demand for high-precision laser applications across different sectors, including industrial manufacturing, medical procedures, scientific research, and military operations. The versatility and efficiency of cubic Nd:YAG crystals make them indispensable in these fields, contributing to the market's growth. As technology advances, the applications of these crystals continue to expand, further fueling the market's development. The global market for cubic Nd:YAG crystals is characterized by ongoing research and innovation, aiming to improve the performance and cost-effectiveness of these materials, thereby broadening their application scope.

Rod, Slab, Disk, Block, Others in the Global Cubic Nd:YAG Crystal Market:

The Global Cubic Nd:YAG Crystal Market is segmented based on the form factor of the crystals, which includes rods, slabs, disks, blocks, and others. Each form factor serves specific applications and offers unique advantages. Rods are the most traditional form of Nd:YAG crystals and are widely used in laser systems due to their simplicity and effectiveness. They are typically cylindrical and are used in applications where a high degree of precision and power is required, such as in industrial cutting and welding. The rod form is favored for its ease of integration into existing laser systems and its ability to produce a consistent and powerful laser beam. Slabs, on the other hand, are rectangular in shape and are used in high-power laser applications. The slab design allows for efficient heat dissipation, which is crucial in maintaining the performance and longevity of the laser system. This form factor is particularly useful in applications that require continuous operation and high energy output, such as in large-scale manufacturing processes. Disks are another form factor used in the Nd:YAG crystal market. They are typically thin and circular, designed for applications that require a compact and lightweight laser system. Disk lasers are known for their high efficiency and are often used in precision machining and medical applications where space and weight are critical considerations. Blocks are larger and more robust, used in applications that demand high power and durability. They are often employed in military and defense applications where the laser system must withstand harsh conditions and deliver reliable performance. The "others" category includes custom shapes and sizes that are tailored to specific applications. These can include non-standard geometries or composite structures that combine different materials to achieve desired properties. The choice of form factor is influenced by the specific requirements of the application, including power output, efficiency, thermal management, and system integration. Each form factor offers distinct advantages and challenges, and the selection process involves careful consideration of these factors to ensure optimal performance and cost-effectiveness. As the demand for laser applications continues to grow, the market for cubic Nd:YAG crystals is expected to expand, with ongoing research and development efforts aimed at enhancing the performance and versatility of these materials.

Industrial Manufacturing, Medical, Scientific Research, Military, Others in the Global Cubic Nd:YAG Crystal Market:

The usage of Global Cubic Nd:YAG Crystal Market spans across various sectors, each benefiting from the unique properties of these crystals. In industrial manufacturing, Nd:YAG crystals are integral to laser systems used for cutting, welding, and engraving. Their ability to produce high-power laser beams with precision makes them ideal for applications that require fine detail and accuracy. The isotropic nature of cubic Nd:YAG crystals ensures consistent performance, which is crucial in maintaining the quality and efficiency of manufacturing processes. In the medical field, Nd:YAG lasers are used in a variety of procedures, including eye surgeries, skin treatments, and dental applications. The precision and control offered by these lasers allow for minimally invasive procedures, reducing recovery times and improving patient outcomes. The versatility of Nd:YAG lasers in targeting specific tissues without damaging surrounding areas makes them a valuable tool in modern medicine. Scientific research also benefits from the use of Nd:YAG crystals, particularly in spectroscopy and material analysis. The ability to produce stable and precise laser beams is essential in experiments that require accurate measurements and observations. Nd:YAG lasers are used in a range of scientific applications, from studying molecular structures to developing new materials. In the military sector, Nd:YAG lasers are used in targeting and range-finding systems, as well as in directed energy weapons. The robustness and reliability of these lasers make them suitable for use in harsh environments, where precision and durability are critical. The ability to deliver high-energy laser beams over long distances is a key advantage in military applications. Other sectors, such as telecommunications and entertainment, also utilize Nd:YAG lasers for various purposes, including data transmission and laser shows. The adaptability and efficiency of cubic Nd:YAG crystals make them a versatile component in a wide range of applications, driving their demand across different industries. As technology continues to evolve, the potential uses for Nd:YAG crystals are expected to expand, further enhancing their role in various fields.

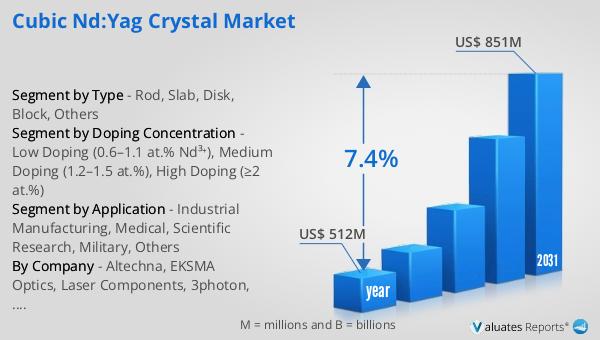

Global Cubic Nd:YAG Crystal Market Outlook:

The global market for Cubic Nd:YAG Crystal was valued at $512 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $851 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.4% during the forecast period. This upward trend is indicative of the increasing demand for Nd:YAG crystals across various industries, driven by their superior optical properties and versatility. The market's expansion is fueled by advancements in laser technology and the growing need for high-precision applications in sectors such as industrial manufacturing, medical procedures, and military operations. As industries continue to seek efficient and reliable laser solutions, the demand for cubic Nd:YAG crystals is expected to rise. The projected growth also reflects ongoing research and development efforts aimed at enhancing the performance and cost-effectiveness of these materials. By improving the quality and capabilities of Nd:YAG crystals, manufacturers can cater to a broader range of applications, further driving market growth. The increasing adoption of laser technologies in emerging markets and the development of new applications are also contributing to the market's positive outlook. As a result, the global cubic Nd:YAG crystal market is poised for substantial growth in the coming years, offering opportunities for innovation and expansion across various sectors.

| Report Metric | Details |

| Report Name | Cubic Nd:YAG Crystal Market |

| Accounted market size in year | US$ 512 million |

| Forecasted market size in 2031 | US$ 851 million |

| CAGR | 7.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Doping Concentration |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Altechna, EKSMA Optics, Laser Components, 3photon, ALPHALAS GmbH, FLIR Systems, Laser Materials Corporation, Komlas GmbH, Fujian Castech Crystals, Chengdu Xinyuan Huibo Photoelectric Technology, Union Optic, Shanghai Kingwin Technology, Changchun Yutai Optics, Fuzhou Laserstates Electronics, MetaLaser Inc., Fuzhou Lambda Optics, MT-Optics, Firesky Crystal Corporation (FSC), Lasertec Inc., WISOPTIC, Avantier, Roditi International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |