What is Global Automatic Gripper Inspection Arms Market?

The Global Automatic Gripper Inspection Arms Market refers to the industry focused on the development, production, and distribution of robotic arms equipped with grippers that are used for inspection purposes. These advanced robotic systems are designed to enhance the efficiency and accuracy of inspection processes across various industries. Automatic gripper inspection arms are equipped with sensors and cameras that allow them to perform detailed inspections of products, components, and assemblies. They are capable of identifying defects, measuring dimensions, and ensuring quality control in manufacturing processes. The market for these robotic arms is driven by the increasing demand for automation in industries such as automotive, electronics, and medical devices, where precision and reliability are crucial. As industries continue to adopt automation to improve productivity and reduce human error, the demand for automatic gripper inspection arms is expected to grow. These systems not only improve inspection accuracy but also reduce the time and cost associated with manual inspections. The market is characterized by continuous technological advancements, with manufacturers focusing on developing more sophisticated and versatile gripper inspection arms to meet the evolving needs of various industries.

Fixed Gripper Inspection Arms, Mobile Gripper Inspection Arms, Collaborative Gripper Inspection Arms, Multi-functional Integrated Inspection Arms, Others in the Global Automatic Gripper Inspection Arms Market:

Fixed Gripper Inspection Arms are a type of robotic arm that remains stationary during the inspection process. These arms are typically mounted on a fixed base and are used in environments where the inspection area is confined or where the objects to be inspected are brought to the arm. Fixed gripper inspection arms are known for their stability and precision, making them ideal for applications that require high accuracy. They are commonly used in industries such as automotive manufacturing and electronics, where components need to be inspected for defects or dimensional accuracy. Mobile Gripper Inspection Arms, on the other hand, are designed to move around the inspection area. These arms are mounted on mobile platforms, allowing them to navigate through different sections of a manufacturing facility or warehouse. Mobile gripper inspection arms are particularly useful in large-scale operations where the inspection area is extensive, and flexibility is required. They can be programmed to follow specific paths or respond to real-time data, making them adaptable to various inspection tasks. Collaborative Gripper Inspection Arms are designed to work alongside human operators. These arms are equipped with advanced safety features that allow them to operate in close proximity to humans without posing a risk. Collaborative gripper inspection arms are used in environments where human oversight is necessary, or where the inspection process requires human intervention. They are commonly used in industries such as medical devices and electronics, where precision and safety are paramount. Multi-functional Integrated Inspection Arms are versatile robotic systems that combine multiple inspection capabilities into a single unit. These arms are equipped with various sensors and tools that allow them to perform a wide range of inspection tasks, from visual inspections to dimensional measurements. Multi-functional integrated inspection arms are ideal for industries that require comprehensive inspection solutions, such as aerospace and machinery parts manufacturing. They offer the advantage of consolidating multiple inspection processes into a single system, reducing the need for multiple machines and improving efficiency. Other types of gripper inspection arms in the market include specialized systems designed for specific applications or industries. These may include arms with unique gripper designs or those equipped with specialized sensors for niche inspection tasks. As the demand for automation and precision in inspection processes continues to grow, manufacturers are developing innovative solutions to meet the diverse needs of different industries. The global market for automatic gripper inspection arms is characterized by a wide range of products, each designed to address specific inspection challenges and improve overall productivity.

Automotive Manufacturing Inspection, Electronics Inspection, Medical Device Inspection, Machinery Parts Inspection, Others in the Global Automatic Gripper Inspection Arms Market:

The Global Automatic Gripper Inspection Arms Market finds extensive usage across various industries, each with its unique set of requirements and challenges. In the automotive manufacturing sector, these robotic arms are used to inspect components such as engine parts, body panels, and interior fittings. The precision and accuracy of automatic gripper inspection arms ensure that each component meets the stringent quality standards required in the automotive industry. By automating the inspection process, manufacturers can reduce the risk of defects and improve the overall quality of their vehicles. In the electronics industry, automatic gripper inspection arms are used to inspect circuit boards, connectors, and other electronic components. The intricate nature of electronic components requires high precision and accuracy during the inspection process. Automatic gripper inspection arms equipped with advanced sensors and cameras can detect even the smallest defects, ensuring that each component functions correctly. This is particularly important in the production of consumer electronics, where reliability and performance are critical. In the medical device industry, automatic gripper inspection arms are used to inspect devices such as surgical instruments, implants, and diagnostic equipment. The high standards of quality and safety required in the medical field make these robotic arms an essential tool for manufacturers. They ensure that each device meets the necessary regulatory requirements and functions as intended. By automating the inspection process, manufacturers can improve the consistency and reliability of their products, ultimately enhancing patient safety. In the machinery parts inspection sector, automatic gripper inspection arms are used to inspect components such as gears, bearings, and shafts. These components are critical to the performance and reliability of machinery, making accurate inspection essential. Automatic gripper inspection arms can perform detailed inspections, measuring dimensions and identifying defects that could affect the performance of the machinery. By ensuring that each component meets the required specifications, manufacturers can improve the reliability and longevity of their machinery. Other industries that benefit from the use of automatic gripper inspection arms include aerospace, food and beverage, and consumer goods. In each of these industries, the need for precision, accuracy, and efficiency drives the adoption of these advanced robotic systems. As industries continue to seek ways to improve productivity and reduce costs, the demand for automatic gripper inspection arms is expected to grow, further expanding their usage across various sectors.

Global Automatic Gripper Inspection Arms Market Outlook:

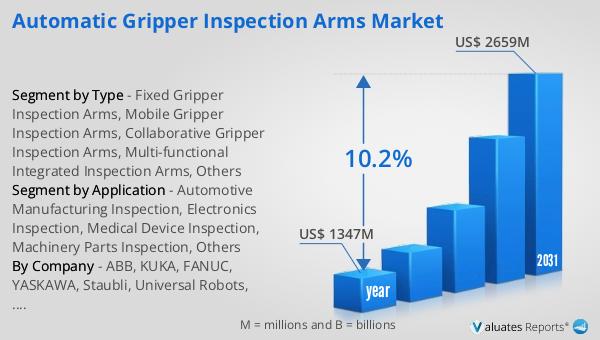

The global market for Automatic Gripper Inspection Arms was valued at $1,347 million in 2024, with projections indicating a significant increase to $2,659 million by 2031. This growth represents a compound annual growth rate (CAGR) of 10.2% over the forecast period. The market's expansion is driven by the increasing demand for automation and precision in inspection processes across various industries. As manufacturers seek to improve productivity and reduce costs, the adoption of automatic gripper inspection arms is expected to rise. These robotic systems offer numerous advantages, including improved accuracy, reduced inspection time, and enhanced quality control. By automating the inspection process, manufacturers can minimize the risk of defects and ensure that their products meet the required standards. The market is characterized by continuous technological advancements, with manufacturers focusing on developing more sophisticated and versatile gripper inspection arms to meet the evolving needs of different industries. As industries continue to adopt automation to improve productivity and reduce human error, the demand for automatic gripper inspection arms is expected to grow, further driving the market's expansion. The increasing adoption of these advanced robotic systems is expected to contribute to the market's growth, as industries seek to improve efficiency and reduce costs.

| Report Metric | Details |

| Report Name | Automatic Gripper Inspection Arms Market |

| Accounted market size in year | US$ 1347 million |

| Forecasted market size in 2031 | US$ 2659 million |

| CAGR | 10.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB, KUKA, FANUC, YASKAWA, Staubli, Universal Robots, Schunk, Zimmer Group, DESTACO, IAI Corporation, SMC Corporation, Festo, Omron Corporation, Keyence, Epson Robots, Comau, Techman Robot, Doosan Robotics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |