What is Global Smart Miniature Stacking Robots Market?

The Global Smart Miniature Stacking Robots Market is an innovative segment within the robotics industry, focusing on the development and deployment of compact, intelligent robots designed for stacking and organizing tasks. These robots are engineered to perform precise and efficient stacking operations in various industrial settings, enhancing productivity and reducing manual labor. The market is driven by advancements in robotics technology, increasing demand for automation, and the need for efficient space utilization in industries such as warehousing, manufacturing, and logistics. Smart miniature stacking robots are equipped with advanced sensors, artificial intelligence, and machine learning capabilities, enabling them to adapt to different environments and tasks. They are designed to handle a wide range of materials and products, from small electronic components to larger items in packaging and logistics. The market is characterized by continuous innovation, with companies investing in research and development to enhance the capabilities and applications of these robots. As industries increasingly adopt automation to improve efficiency and reduce costs, the demand for smart miniature stacking robots is expected to grow, offering significant opportunities for market players to expand their product offerings and reach new customers.

Single-arm Stacking Robots, Dual-arm Stacking Robots in the Global Smart Miniature Stacking Robots Market:

Single-arm stacking robots and dual-arm stacking robots are two primary types of robots within the Global Smart Miniature Stacking Robots Market, each offering unique capabilities and applications. Single-arm stacking robots are designed with one robotic arm, which is equipped with end-effectors or grippers to handle and stack items. These robots are typically used in applications where space is limited, and tasks require precision and speed. Single-arm robots are ideal for handling small to medium-sized items, such as electronic components, small packages, and lightweight materials. They are often used in industries like electronics manufacturing, where precision and accuracy are crucial. The compact design of single-arm robots allows them to operate in confined spaces, making them suitable for environments with limited floor space. On the other hand, dual-arm stacking robots are equipped with two robotic arms, providing greater flexibility and capability in handling and stacking tasks. The dual-arm design allows these robots to perform more complex operations, such as simultaneously handling multiple items or performing tasks that require coordination between two arms. Dual-arm robots are often used in applications that require higher payload capacities and more intricate handling, such as in the food and beverage packaging industry, where they can handle larger and heavier items. The dual-arm configuration also enables these robots to perform tasks that mimic human-like movements, making them suitable for applications that require dexterity and precision. Both single-arm and dual-arm stacking robots are equipped with advanced technologies, such as sensors, cameras, and artificial intelligence, enabling them to adapt to different tasks and environments. These technologies allow the robots to recognize and manipulate various objects, adjust to changes in the environment, and optimize their operations for efficiency and accuracy. The choice between single-arm and dual-arm stacking robots depends on the specific requirements of the application, including the size and weight of the items to be handled, the complexity of the tasks, and the available space. As the Global Smart Miniature Stacking Robots Market continues to evolve, manufacturers are focusing on enhancing the capabilities of both single-arm and dual-arm robots to meet the diverse needs of industries. Innovations in robotics technology, such as improved sensors, machine learning algorithms, and collaborative capabilities, are driving the development of more advanced and versatile stacking robots. These advancements are expected to expand the applications of single-arm and dual-arm stacking robots, enabling them to perform a wider range of tasks and operate in more challenging environments. As industries increasingly adopt automation to improve efficiency and reduce labor costs, the demand for both single-arm and dual-arm stacking robots is expected to grow, offering significant opportunities for market players to innovate and expand their product offerings.

Warehouse Automation, Electronics Manufacturing, Food and Beverage Packaging, Medical and Pharmaceutical Logistics, Others in the Global Smart Miniature Stacking Robots Market:

The Global Smart Miniature Stacking Robots Market finds extensive usage across various industries, including warehouse automation, electronics manufacturing, food and beverage packaging, medical and pharmaceutical logistics, and others. In warehouse automation, smart miniature stacking robots play a crucial role in optimizing storage and retrieval processes. These robots are designed to navigate through narrow aisles and confined spaces, efficiently stacking and organizing products to maximize storage capacity. By automating repetitive and labor-intensive tasks, these robots help warehouses improve operational efficiency, reduce errors, and lower labor costs. In electronics manufacturing, smart miniature stacking robots are used to handle delicate and small components with precision and accuracy. These robots are equipped with advanced sensors and grippers that enable them to manipulate tiny parts without causing damage. By automating the assembly and stacking processes, these robots enhance production speed and quality, allowing manufacturers to meet the growing demand for electronic devices. In the food and beverage packaging industry, smart miniature stacking robots are used to handle a wide range of packaging materials and products. These robots are capable of stacking and organizing items of various shapes and sizes, ensuring efficient packaging and distribution. By automating the packaging process, these robots help companies improve productivity, reduce waste, and maintain high standards of hygiene and safety. In medical and pharmaceutical logistics, smart miniature stacking robots are used to handle sensitive and high-value products, such as medicines and medical devices. These robots are designed to operate in controlled environments, ensuring the safe and efficient handling of products. By automating the storage and retrieval processes, these robots help companies maintain accurate inventory levels, reduce the risk of errors, and ensure timely delivery of products. In addition to these industries, smart miniature stacking robots are also used in other sectors, such as automotive manufacturing, retail, and e-commerce. These robots are designed to adapt to different environments and tasks, making them versatile tools for a wide range of applications. As industries continue to embrace automation to improve efficiency and reduce costs, the demand for smart miniature stacking robots is expected to grow, offering significant opportunities for market players to expand their reach and develop innovative solutions.

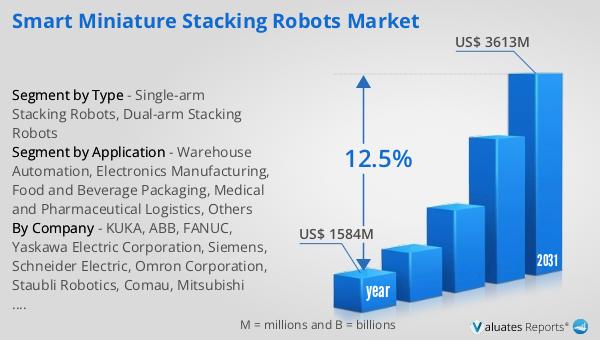

Global Smart Miniature Stacking Robots Market Outlook:

The outlook for the Global Smart Miniature Stacking Robots Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 1584 million, reflecting the increasing adoption of these advanced robotic solutions across various industries. By 2031, the market is projected to expand to a revised size of US$ 3613 million, driven by a compound annual growth rate (CAGR) of 12.5% during the forecast period. This robust growth is indicative of the rising demand for automation and efficiency in industrial operations, as companies seek to enhance productivity and reduce labor costs. The market's expansion is fueled by technological advancements in robotics, including the integration of artificial intelligence, machine learning, and advanced sensors, which enhance the capabilities and versatility of smart miniature stacking robots. As industries such as warehousing, manufacturing, and logistics continue to evolve, the need for efficient and reliable automation solutions becomes increasingly critical. The Global Smart Miniature Stacking Robots Market is poised to play a pivotal role in meeting this demand, offering innovative solutions that cater to the diverse needs of various sectors. With continuous innovation and investment in research and development, market players are well-positioned to capitalize on the growing opportunities and drive the market's growth in the coming years.

| Report Metric | Details |

| Report Name | Smart Miniature Stacking Robots Market |

| Accounted market size in year | US$ 1584 million |

| Forecasted market size in 2031 | US$ 3613 million |

| CAGR | 12.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KUKA, ABB, FANUC, Yaskawa Electric Corporation, Siemens, Schneider Electric, Omron Corporation, Staubli Robotics, Comau, Mitsubishi Electric, Panasonic Industry, Rockwell Automation, Elettric 80, SICK AG, Bosch Rexroth, Universal Robots, Intralox, Honeywell Robotics, Dematic, TGW Logistics Group, Daifuku Co Ltd, Vanderlande, Jungheinrich AG, Hyster-Yale Materials Handling, Hikrobot, Geek+, GreyOrange, Magazino |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |