What is Global Electrical Discharge Machining Services Market?

The Global Electrical Discharge Machining (EDM) Services Market is a specialized sector within the manufacturing industry that focuses on the use of electrical discharge machining technology to shape and finish metal components. EDM is a non-traditional machining process that uses electrical discharges or sparks to remove material from a workpiece. This process is particularly useful for creating complex shapes and intricate details that are difficult to achieve with traditional machining methods. The market for EDM services is driven by the demand for precision engineering in industries such as aerospace, automotive, electronics, and medical devices. These industries require high levels of accuracy and surface finish, which EDM can provide. The global market is characterized by a diverse range of service providers, from small specialized firms to large multinational companies, all offering various EDM solutions tailored to specific industrial needs. As technology advances, the EDM services market continues to evolve, incorporating new techniques and materials to enhance efficiency and precision. This market plays a crucial role in modern manufacturing, enabling the production of high-quality components that meet stringent industry standards.

Sinker EDM, Wire EDM, Hole Drilling EDM in the Global Electrical Discharge Machining Services Market:

Sinker EDM, Wire EDM, and Hole Drilling EDM are three primary types of electrical discharge machining processes that cater to different manufacturing needs within the Global Electrical Discharge Machining Services Market. Sinker EDM, also known as Ram EDM, involves using a specially shaped electrode submerged in a dielectric fluid to erode material from the workpiece. This method is ideal for creating complex cavities and intricate shapes in hard materials, making it popular in mold-making and tool-and-die industries. The dielectric fluid acts as an insulator and coolant, preventing overheating and ensuring precise material removal. Wire EDM, on the other hand, uses a thin, electrically charged wire to cut through metal. This process is highly accurate and is often used for producing intricate parts with tight tolerances. Wire EDM is particularly beneficial for cutting complex shapes and contours in hard materials, such as titanium and hardened steel, without causing thermal distortion. It is widely used in the aerospace and medical device industries, where precision is paramount. Hole Drilling EDM, also known as Fast Hole EDM, is specifically designed for drilling small, deep holes with high aspect ratios. This process is essential in applications where traditional drilling methods are ineffective, such as creating cooling holes in turbine blades or fuel injector nozzles. The ability to drill precise holes in hard materials makes Hole Drilling EDM a valuable tool in the aerospace and automotive sectors. Each of these EDM processes offers unique advantages, allowing manufacturers to choose the most suitable method for their specific requirements. The versatility and precision of EDM technology make it an indispensable part of modern manufacturing, enabling the production of complex components with high accuracy and efficiency.

Prototype Production, Coinage Die Making, Small Hole Drilling, Metal Disintegration Machining, Closed Loop Manufacturing, Others in the Global Electrical Discharge Machining Services Market:

The Global Electrical Discharge Machining Services Market finds extensive applications in various areas, including prototype production, coinage die making, small hole drilling, metal disintegration machining, closed-loop manufacturing, and others. In prototype production, EDM services are invaluable for creating precise and intricate prototypes that closely resemble the final product. This capability allows manufacturers to test and refine designs before mass production, reducing the risk of costly errors and ensuring product quality. Coinage die making is another critical application of EDM services, where the technology is used to create detailed and durable dies for minting coins. The precision and repeatability of EDM make it ideal for producing high-quality dies that can withstand the rigors of mass production. Small hole drilling is a specialized application of EDM, where the technology is used to drill tiny, precise holes in hard materials. This capability is essential in industries such as aerospace and automotive, where components often require small holes for cooling or lubrication purposes. Metal disintegration machining is a unique application of EDM, used to remove broken tools or fasteners from workpieces without damaging the surrounding material. This process is particularly useful in maintenance and repair operations, where traditional methods may be ineffective or cause further damage. Closed-loop manufacturing is an advanced application of EDM services, where the technology is integrated into automated production systems to ensure consistent quality and precision. This approach allows manufacturers to achieve high levels of efficiency and accuracy, reducing waste and improving overall productivity. Other applications of EDM services include the production of complex components for the medical device, electronics, and defense industries, where precision and reliability are critical. The versatility and precision of EDM technology make it an essential tool in modern manufacturing, enabling the production of high-quality components that meet the stringent demands of various industries.

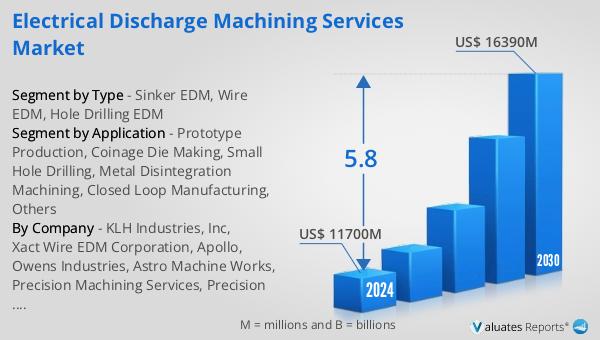

Global Electrical Discharge Machining Services Market Outlook:

The global market for Electrical Discharge Machining Services was valued at US$ 12,300 million in 2024 and is anticipated to expand to a revised size of US$ 18,130 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% during the forecast period. This growth trajectory underscores the increasing demand for precision machining solutions across various industries. As manufacturers strive to meet the evolving needs of sectors such as aerospace, automotive, and electronics, the adoption of EDM services is expected to rise. The market's expansion is driven by the need for high-precision components that traditional machining methods cannot achieve. EDM technology offers unparalleled accuracy and efficiency, making it an attractive option for manufacturers seeking to enhance their production capabilities. Additionally, advancements in EDM technology, such as the development of new materials and techniques, are expected to further fuel market growth. As the global manufacturing landscape continues to evolve, the demand for EDM services is likely to increase, driven by the need for precision, efficiency, and innovation. This market outlook highlights the significant role that EDM services play in modern manufacturing, enabling the production of high-quality components that meet the stringent demands of various industries.

| Report Metric | Details |

| Report Name | Electrical Discharge Machining Services Market |

| Accounted market size in year | US$ 12300 million |

| Forecasted market size in 2031 | US$ 18130 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | KLH Industries, Inc, Xact Wire EDM Corporation, Apollo, Owens Industries, Astro Machine Works, Precision Machining Services, Precision Metal Machining, Inc, H&W Tool Company, EMF, Inc, Aerospace Alloys, Inc, Arbiser Machine Inc, Mallory Industries, eMachineShop, Get It Made, EDM Technologies, Inc, Gensun Precision Machining Co., Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |