What is Global 3-axis Vertical Machining Centers Sales Market?

The Global 3-axis Vertical Machining Centers Sales Market refers to the worldwide trade and distribution of 3-axis vertical machining centers, which are essential tools in the manufacturing industry. These machines are designed to perform a variety of tasks such as drilling, cutting, and milling with high precision and efficiency. They operate on three axes, allowing for the movement of the cutting tool in three-dimensional space, which is crucial for creating complex parts and components. The market for these machines is driven by the demand from industries such as automotive, aerospace, and electronics, where precision and efficiency are paramount. As technology advances, these machines are becoming more sophisticated, offering features like automated tool changers and advanced control systems, which enhance their capabilities and appeal to a broader range of industries. The global market is characterized by a mix of established manufacturers and new entrants, each striving to innovate and capture a share of this dynamic and competitive market.

in the Global 3-axis Vertical Machining Centers Sales Market:

The Global 3-axis Vertical Machining Centers Sales Market offers a variety of types to cater to the diverse needs of its customers. These types are primarily distinguished by their speed, size, and technological features. The low-speed type, which holds the largest market share, is favored for its reliability and cost-effectiveness. It is particularly popular among small to medium-sized enterprises that require precision machining without the need for high-speed operations. These machines are ideal for producing parts that do not require rapid production cycles but demand high accuracy and consistency. On the other hand, high-speed types are designed for industries that prioritize speed and efficiency, such as the automotive and aerospace sectors. These machines are equipped with advanced spindle technology and enhanced cooling systems to handle the demands of high-speed operations, making them suitable for mass production and complex machining tasks. Additionally, there are specialized types that incorporate advanced features like multi-axis capabilities and automated tool changers. These machines are designed for industries that require flexibility and the ability to perform a wide range of machining operations without manual intervention. The integration of computer numerical control (CNC) technology in these machines has further expanded their capabilities, allowing for greater precision and automation. CNC-controlled machines are particularly popular in industries that require intricate designs and high levels of customization, such as the electronics and medical device sectors. Furthermore, the market also includes compact and portable types that are designed for workshops with limited space. These machines offer the same level of precision and functionality as their larger counterparts but in a more compact form factor, making them ideal for small workshops and educational institutions. The diversity in types ensures that there is a suitable option for every customer, regardless of their specific needs or budget constraints. As the market continues to evolve, manufacturers are focusing on developing machines that offer a balance between performance, cost, and technological advancement, ensuring that they meet the ever-changing demands of the global market.

in the Global 3-axis Vertical Machining Centers Sales Market:

The applications of 3-axis vertical machining centers are vast and varied, reflecting their versatility and importance in modern manufacturing. One of the primary applications is in the automotive industry, where these machines are used to produce a wide range of components, from engine parts to intricate dashboard elements. The precision and efficiency of 3-axis machining centers make them ideal for producing parts that require tight tolerances and high-quality finishes. In the aerospace industry, these machines are used to manufacture critical components such as turbine blades and structural parts. The ability to machine complex geometries with high precision is crucial in this sector, where safety and performance are paramount. Additionally, the electronics industry relies heavily on 3-axis machining centers for the production of components such as circuit boards and connectors. The precision and repeatability of these machines ensure that electronic components meet the stringent quality standards required in this industry. In the medical sector, 3-axis machining centers are used to produce a variety of medical devices and implants. The ability to machine complex shapes and fine details is essential for creating components that meet the specific needs of patients. Furthermore, these machines are used in the production of molds and dies, which are essential for mass production in various industries. The versatility of 3-axis machining centers allows them to be used in a wide range of applications, from producing simple parts to complex assemblies. As technology continues to advance, the applications of these machines are expected to expand further, driven by the demand for precision and efficiency in manufacturing.

Global 3-axis Vertical Machining Centers Sales Market Outlook:

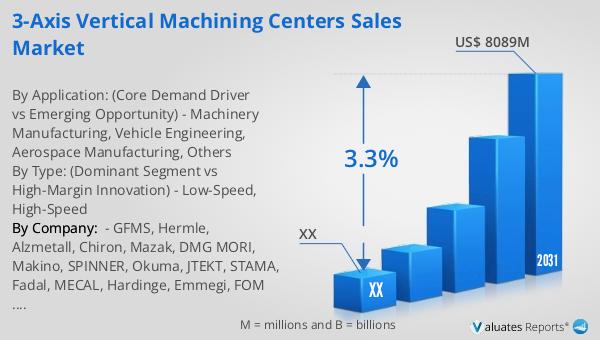

The global market for 3-axis vertical machining centers is projected to grow significantly in the coming years. In 2024, the market size was valued at approximately $6,465 million, and it is expected to reach an adjusted size of $8,089 million by 2031, with a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2025 to 2031. The market is dominated by the top five manufacturers, who collectively hold a market share of over 15%. Europe is the largest regional market, accounting for about 30% of the global share, followed by China, which holds a share of over 20%. In terms of product segments, the low-speed type is the largest, with a market share exceeding 55%. This segment's dominance can be attributed to its cost-effectiveness and reliability, making it a popular choice among small to medium-sized enterprises. The market's growth is driven by the increasing demand for precision machining in various industries, including automotive, aerospace, and electronics. As manufacturers continue to innovate and develop new technologies, the market is expected to witness further growth and diversification.

| Report Metric | Details |

| Report Name | 3-axis Vertical Machining Centers Sales Market |

| Forecasted market size in 2031 | US$ 8089 million |

| CAGR | 3.3% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | GFMS, Hermle, Alzmetall, Chiron, Mazak, DMG MORI, Makino, SPINNER, Okuma, JTEKT, STAMA, Fadal, MECAL, Hardinge, Emmegi, FOM Industrie, HAAS, CB Ferrari, FIDIA, Hurco, Schaublin, YCM, AWEA, Accuway, SMTCL, JFMT, DMTG, Hanland, RIFA, BYJC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |