What is Global Vision Inspection System for Pharmaceutical Market?

The Global Vision Inspection System for the Pharmaceutical Market is a sophisticated technology designed to ensure the quality and safety of pharmaceutical products. This system plays a crucial role in the pharmaceutical industry by providing automated inspection solutions that help in detecting defects, contaminants, and inconsistencies in products such as tablets, capsules, and other dosage forms. By utilizing advanced imaging and processing technologies, these systems can perform high-speed inspections with remarkable accuracy, reducing the risk of human error and ensuring compliance with stringent regulatory standards. The implementation of vision inspection systems helps pharmaceutical companies maintain product integrity, enhance operational efficiency, and protect consumer safety. These systems are equipped with features like high-resolution cameras, lighting systems, and software algorithms that analyze images to identify defects such as cracks, chips, discoloration, and foreign particles. As the pharmaceutical industry continues to grow and evolve, the demand for reliable and efficient inspection systems is expected to rise, making the Global Vision Inspection System an indispensable tool for quality assurance in pharmaceutical manufacturing.

Fully Automatic, Semi Automatic in the Global Vision Inspection System for Pharmaceutical Market:

The Global Vision Inspection System for the Pharmaceutical Market can be categorized into two main types: Fully Automatic and Semi-Automatic systems. Fully Automatic Vision Inspection Systems are designed to operate with minimal human intervention, providing a seamless and efficient inspection process. These systems are equipped with advanced technologies such as machine learning algorithms, high-speed cameras, and robotic arms that enable them to perform complex inspections at high speeds. They are capable of inspecting a wide range of pharmaceutical products, including tablets, capsules, and vials, with precision and accuracy. The fully automatic systems are ideal for large-scale production environments where speed and efficiency are critical. They can handle high volumes of products, ensuring that each item is thoroughly inspected for defects and inconsistencies. The use of fully automatic systems helps pharmaceutical companies reduce labor costs, minimize human error, and increase overall productivity. On the other hand, Semi-Automatic Vision Inspection Systems require some level of human intervention to operate. These systems are typically used in smaller production environments or for specialized inspection tasks that require a more hands-on approach. Semi-automatic systems combine the benefits of automation with the flexibility of manual inspection, allowing operators to focus on specific areas of concern while the system handles routine inspection tasks. This hybrid approach provides a balance between efficiency and control, making it suitable for applications where human judgment is still necessary. Both fully automatic and semi-automatic systems offer significant advantages in terms of quality control and compliance with regulatory standards. They help pharmaceutical companies maintain high levels of product quality, reduce waste, and ensure that products meet the required specifications before reaching the market. As the pharmaceutical industry continues to face increasing pressure to improve quality and efficiency, the adoption of vision inspection systems is expected to grow, driving innovation and advancements in this field.

Capsules, Tablets, Others in the Global Vision Inspection System for Pharmaceutical Market:

The Global Vision Inspection System for the Pharmaceutical Market is extensively used in the inspection of various pharmaceutical products, including capsules, tablets, and others. In the case of capsules, these systems are designed to detect defects such as cracks, splits, and foreign particles that may compromise the integrity and safety of the product. The high-resolution cameras and advanced imaging technologies used in these systems allow for detailed inspection of each capsule, ensuring that only products that meet the required quality standards are approved for distribution. For tablets, the vision inspection systems are used to identify defects such as chips, discoloration, and incorrect dimensions. The systems can also detect issues related to tablet coating and surface finish, which are critical for ensuring the efficacy and safety of the medication. By providing a thorough and accurate inspection process, these systems help pharmaceutical companies maintain high levels of quality control and compliance with regulatory standards. In addition to capsules and tablets, vision inspection systems are also used for other pharmaceutical products such as vials, ampoules, and syringes. These systems are capable of inspecting the entire surface of the product, detecting defects such as cracks, leaks, and contamination. The use of vision inspection systems in these areas helps ensure that products are safe for use and free from defects that could pose a risk to patient safety. Overall, the Global Vision Inspection System for the Pharmaceutical Market plays a vital role in ensuring the quality and safety of pharmaceutical products, helping companies meet the increasing demands for high-quality medications.

Global Vision Inspection System for Pharmaceutical Market Outlook:

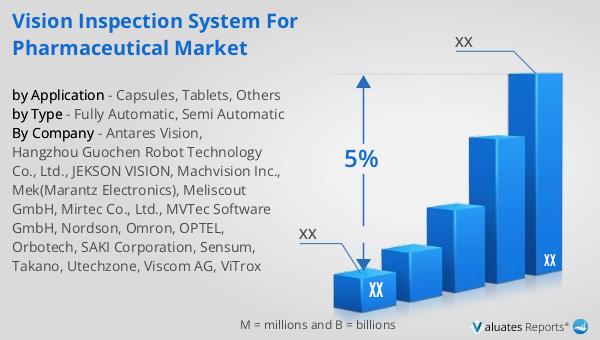

The outlook for the Global Vision Inspection System for the Pharmaceutical Market is closely tied to the broader trends in the pharmaceutical industry. As of 2022, the global pharmaceutical market is valued at approximately 1,475 billion USD, with an expected compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by factors such as increasing demand for medications, advancements in drug development, and the need for stringent quality control measures. In comparison, the chemical drug market has seen a steady increase, growing from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth highlights the importance of quality assurance and inspection systems in maintaining the integrity and safety of pharmaceutical products. As the pharmaceutical market continues to expand, the demand for reliable and efficient vision inspection systems is expected to rise, driving innovation and advancements in this field. The adoption of these systems will be crucial for pharmaceutical companies looking to improve their quality control processes, reduce waste, and ensure compliance with regulatory standards. Overall, the Global Vision Inspection System for the Pharmaceutical Market is poised for significant growth, driven by the increasing need for high-quality medications and the ongoing advancements in inspection technology.

| Report Metric | Details |

| Report Name | Vision Inspection System for Pharmaceutical Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Antares Vision, Hangzhou Guochen Robot Technology Co., Ltd., JEKSON VISION, Machvision Inc., Mek(Marantz Electronics), Meliscout GmbH, Mirtec Co., Ltd., MVTec Software GmbH, Nordson, Omron, OPTEL, Orbotech, SAKI Corporation, Sensum, Takano, Utechzone, Viscom AG, ViTrox |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |