What is Global Tungsten Carbide Tubular Electrode Market?

The Global Tungsten Carbide Tubular Electrode Market is a specialized segment within the broader industrial materials sector, focusing on the production and distribution of tungsten carbide tubular electrodes. These electrodes are essential components in various industrial applications due to their exceptional hardness, wear resistance, and ability to withstand high temperatures. Tungsten carbide, a compound composed of tungsten and carbon, is renowned for its durability and strength, making it an ideal material for demanding environments. The tubular form of these electrodes allows for efficient use in welding and cutting applications, where precision and reliability are paramount. Industries such as aerospace, automotive, and manufacturing heavily rely on these electrodes to enhance the performance and longevity of their machinery and tools. As global industries continue to evolve and demand more robust materials, the tungsten carbide tubular electrode market is poised for growth, driven by technological advancements and the increasing need for high-performance materials in various sectors. The market's expansion is further supported by ongoing research and development efforts aimed at improving the properties and applications of tungsten carbide, ensuring its relevance in the ever-changing industrial landscape.

Sintered WC Particles, Casting WC Particles, Single Crystal WC Particles in the Global Tungsten Carbide Tubular Electrode Market:

Sintered WC Particles, Casting WC Particles, and Single Crystal WC Particles are three distinct forms of tungsten carbide particles used in the Global Tungsten Carbide Tubular Electrode Market, each offering unique properties and applications. Sintered WC Particles are created through a process called sintering, where tungsten carbide powder is compacted and heated to just below its melting point, causing the particles to bond together. This process results in a dense, hard material that is highly resistant to wear and corrosion, making it ideal for applications requiring durability and longevity. Sintered WC Particles are commonly used in cutting tools, mining equipment, and wear-resistant coatings, where their toughness and ability to withstand harsh conditions are highly valued. Casting WC Particles, on the other hand, are produced by melting tungsten carbide and pouring it into molds to form specific shapes. This method allows for greater flexibility in the design and production of complex components, making it suitable for applications where precision and customization are critical. Casting WC Particles are often used in the manufacturing of intricate parts for the aerospace and automotive industries, where their strength and versatility are essential. Single Crystal WC Particles represent the pinnacle of tungsten carbide technology, offering unparalleled hardness and thermal stability. These particles are grown as individual crystals, resulting in a material with a uniform structure and exceptional mechanical properties. Single Crystal WC Particles are used in high-performance applications where maximum strength and resistance to extreme temperatures are required, such as in cutting-edge aerospace components and advanced manufacturing processes. The choice between these different forms of tungsten carbide particles depends on the specific requirements of the application, with each offering distinct advantages in terms of performance, cost, and manufacturability. As the Global Tungsten Carbide Tubular Electrode Market continues to grow, the demand for these specialized particles is expected to increase, driven by the need for more efficient and durable materials in a wide range of industries.

Petroleum Drilling Tools, Construction, Building Materials Machinery, Mining Geological Tools, Agricultural Machinery, Others in the Global Tungsten Carbide Tubular Electrode Market:

The Global Tungsten Carbide Tubular Electrode Market finds extensive usage across various sectors, including petroleum drilling tools, construction, building materials machinery, mining geological tools, agricultural machinery, and others. In the petroleum industry, tungsten carbide tubular electrodes are crucial for drilling tools due to their ability to withstand extreme pressures and temperatures encountered during drilling operations. Their hardness and wear resistance ensure that the drilling tools maintain their integrity and performance over extended periods, reducing downtime and maintenance costs. In construction and building materials machinery, these electrodes are used in equipment such as concrete mixers, crushers, and road construction machinery, where their durability and resistance to abrasion are essential for handling tough materials and harsh working conditions. The mining industry also benefits significantly from tungsten carbide tubular electrodes, particularly in geological tools used for exploration and extraction. The electrodes' toughness and resistance to wear make them ideal for cutting through hard rock formations and other challenging environments, enhancing the efficiency and effectiveness of mining operations. In agricultural machinery, tungsten carbide tubular electrodes are used in equipment such as plows, harvesters, and tillers, where their strength and wear resistance contribute to improved performance and longevity. The ability of these electrodes to withstand the rigors of agricultural work ensures that machinery operates efficiently, reducing the need for frequent repairs and replacements. Beyond these specific applications, tungsten carbide tubular electrodes are also used in various other industries where high-performance materials are required. Their versatility and reliability make them a preferred choice for manufacturers seeking to enhance the durability and efficiency of their products. As industries continue to demand more robust and efficient materials, the Global Tungsten Carbide Tubular Electrode Market is expected to expand, driven by the increasing need for high-performance solutions across a wide range of applications.

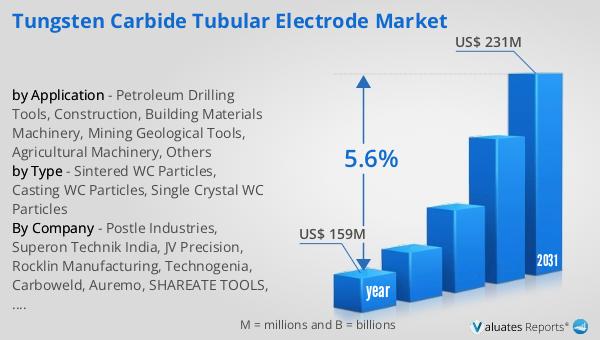

Global Tungsten Carbide Tubular Electrode Market Outlook:

The global market for Tungsten Carbide Tubular Electrode was valued at $159 million in 2024 and is anticipated to grow to a revised size of $231 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period. This growth trajectory underscores the increasing demand for tungsten carbide tubular electrodes across various industries, driven by their exceptional properties and wide-ranging applications. The market's expansion is fueled by the ongoing need for durable and high-performance materials in sectors such as aerospace, automotive, construction, and mining. As industries continue to evolve and face new challenges, the demand for materials that can withstand extreme conditions and deliver reliable performance is expected to rise. The projected growth of the Tungsten Carbide Tubular Electrode Market highlights the importance of these materials in meeting the demands of modern industrial applications. With advancements in technology and manufacturing processes, the market is poised to capitalize on new opportunities and expand its reach across different regions and industries. The increasing focus on sustainability and efficiency in industrial operations further supports the market's growth, as tungsten carbide tubular electrodes offer a reliable solution for enhancing the performance and longevity of machinery and tools. As the market continues to evolve, stakeholders are likely to invest in research and development to explore new applications and improve the properties of tungsten carbide tubular electrodes, ensuring their continued relevance in the ever-changing industrial landscape.

| Report Metric | Details |

| Report Name | Tungsten Carbide Tubular Electrode Market |

| Accounted market size in year | US$ 159 million |

| Forecasted market size in 2031 | US$ 231 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Postle Industries, Superon Technik India, JV Precision, Rocklin Manufacturing, Technogenia, Carboweld, Auremo, SHAREATE TOOLS, Zhuzhou JWE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |