What is Global Thick Film Ceramic Substrates Market?

The Global Thick Film Ceramic Substrates Market is a specialized segment within the broader electronics and materials industry, focusing on the production and application of ceramic substrates that are coated with thick film materials. These substrates are essential components in various electronic devices due to their excellent thermal conductivity, electrical insulation, and mechanical stability. They are primarily used in applications that require high reliability and performance under extreme conditions, such as in automotive electronics, industrial machinery, and telecommunications. The market is driven by the increasing demand for miniaturized and efficient electronic devices, which require substrates that can support high-density circuitry and withstand high temperatures. Additionally, advancements in technology and materials science have led to the development of substrates with enhanced properties, further fueling market growth. The market is characterized by a competitive landscape with several key players investing in research and development to innovate and improve product offerings. As industries continue to evolve and demand more sophisticated electronic components, the Global Thick Film Ceramic Substrates Market is expected to expand, offering new opportunities for manufacturers and suppliers.

Alumina Thick Film Substrates, AlN Thick Film Substrates, BeO Thick Film Substrates in the Global Thick Film Ceramic Substrates Market:

Alumina Thick Film Substrates, AlN Thick Film Substrates, and BeO Thick Film Substrates are three primary types of substrates used in the Global Thick Film Ceramic Substrates Market, each with unique properties and applications. Alumina Thick Film Substrates are the most widely used due to their excellent electrical insulation, high thermal conductivity, and cost-effectiveness. They are made from aluminum oxide and are commonly used in applications that require reliable performance under high temperatures and electrical loads, such as in power electronics and automotive sensors. AlN Thick Film Substrates, or Aluminum Nitride substrates, offer superior thermal conductivity compared to alumina, making them ideal for high-power applications where efficient heat dissipation is critical. They are often used in power devices, LEDs, and RF applications where thermal management is a priority. BeO Thick Film Substrates, or Beryllium Oxide substrates, provide the highest thermal conductivity among the three, along with excellent electrical insulation. However, due to the toxicity of beryllium, their use is limited to specific applications where their unique properties are indispensable, such as in military and aerospace applications. Each type of substrate plays a crucial role in the market, catering to different needs based on their thermal and electrical properties. The choice of substrate depends on the specific requirements of the application, including factors such as operating temperature, power density, and environmental conditions. As technology advances and the demand for high-performance electronic components increases, the development and application of these substrates are expected to grow, driving innovation and competition in the market. Manufacturers are continually exploring new materials and processes to enhance the performance and reduce the cost of these substrates, ensuring they meet the evolving needs of various industries.

Automotive & Sensors, Industrial & Medical, Power Device, LEDs, MEMS Packages, Military & Defense, Others in the Global Thick Film Ceramic Substrates Market:

The Global Thick Film Ceramic Substrates Market finds extensive usage across several key areas, including Automotive & Sensors, Industrial & Medical, Power Devices, LEDs, MEMS Packages, Military & Defense, and others. In the automotive sector, these substrates are crucial for developing advanced sensors and control units that require high reliability and performance under extreme conditions. They are used in engine control units, transmission systems, and various sensors that monitor vehicle performance and safety. In the industrial and medical fields, thick film ceramic substrates are used in equipment that demands high precision and durability, such as medical imaging devices, industrial automation systems, and diagnostic equipment. Their ability to withstand high temperatures and harsh environments makes them ideal for these applications. Power devices, such as inverters and converters, rely on these substrates for efficient thermal management and electrical insulation, ensuring reliable operation and longevity. In the LED industry, thick film ceramic substrates are used to enhance thermal performance and improve the efficiency and lifespan of LED products. MEMS packages, which are used in a variety of applications from consumer electronics to aerospace, benefit from the substrates' ability to support miniaturization and high-density circuitry. In the military and defense sector, the substrates are used in communication systems, radar equipment, and other critical applications that require robust performance and reliability. Other applications include telecommunications, where they are used in base stations and network infrastructure, and consumer electronics, where they support the development of compact and efficient devices. The versatility and performance of thick film ceramic substrates make them indispensable in these areas, driving demand and innovation in the market. As industries continue to evolve and require more advanced electronic components, the usage of these substrates is expected to expand, offering new opportunities for growth and development.

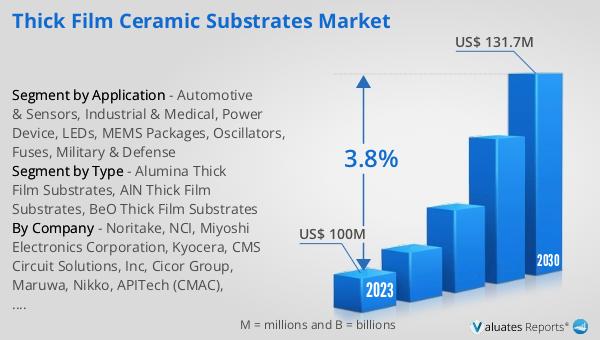

Global Thick Film Ceramic Substrates Market Outlook:

The outlook for the Global Thick Film Ceramic Substrates Market indicates a steady growth trajectory, with the market valued at approximately US$ 114 million in 2024 and projected to reach around US$ 149 million by 2031, growing at a compound annual growth rate (CAGR) of 3.9% during the forecast period. The market is characterized by a competitive landscape, with the top three manufacturers holding a significant share of over 27%. Among the various product segments, alumina thick film substrates dominate the market, accounting for about 77% of the total share. This dominance is attributed to their widespread use and cost-effectiveness compared to other substrate types. The market is also influenced by the presence of key players, with the top six companies collectively holding approximately 42% of the market share in 2024. These companies are actively investing in research and development to innovate and improve their product offerings, ensuring they meet the evolving needs of various industries. As the demand for high-performance electronic components continues to grow, the Global Thick Film Ceramic Substrates Market is expected to expand, offering new opportunities for manufacturers and suppliers to capitalize on. The market's growth is driven by the increasing demand for miniaturized and efficient electronic devices, advancements in technology and materials science, and the need for reliable and high-performance substrates in various applications.

| Report Metric | Details |

| Report Name | Thick Film Ceramic Substrates Market |

| Accounted market size in year | US$ 114 million |

| Forecasted market size in 2031 | US$ 149 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Noritake, NCI, Miyoshi Electronics Corporation, Kyocera, CMS Circuits, Inc, Cicor Group, Maruwa, Nikko, APITech (CMAC), Mitsuboshi Belting, TTM Technologies, MST (Micro Systems Technologies), Micro-Precision Technologies, Stellar Industries Corp, Remtec, NEO Tech, Holy Stone, Tong Hsing, ELCERAM, ECRIM, SERMA Microelectronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |