What is Global Sterility Production Isolator Market?

The Global Sterility Production Isolator Market is a specialized segment within the broader medical and pharmaceutical equipment industry. These isolators are designed to create a controlled environment that ensures sterility during the production and handling of sensitive materials, such as pharmaceuticals and biological products. They are essential in preventing contamination and maintaining the integrity of products that require high levels of cleanliness. The market for sterility production isolators is driven by the increasing demand for sterile manufacturing processes in the pharmaceutical and biotechnology sectors, as well as in hospitals and diagnostic labs. These isolators are crucial for maintaining compliance with stringent regulatory standards that govern the production of sterile products. As the healthcare industry continues to grow and evolve, the need for advanced sterility solutions is expected to rise, further propelling the market for these isolators. The market is characterized by technological advancements, with manufacturers focusing on developing isolators that offer enhanced performance, ease of use, and cost-effectiveness. Overall, the Global Sterility Production Isolator Market plays a vital role in ensuring the safety and efficacy of medical and pharmaceutical products, making it an indispensable component of the healthcare industry.

Class II, Class III, Others in the Global Sterility Production Isolator Market:

In the Global Sterility Production Isolator Market, isolators are categorized into different classes based on their design and functionality, primarily Class II, Class III, and others. Class II isolators are widely used in laboratories and production facilities where moderate levels of protection are required. These isolators provide a controlled environment that protects both the product and the operator from contamination. They are equipped with HEPA filters and airflow systems that ensure a clean and sterile environment. Class II isolators are commonly used in applications such as tissue culture, pharmaceutical compounding, and microbiological testing. They are designed to handle low to moderate risk agents and are suitable for a wide range of applications in the pharmaceutical and biotechnology industries.

Hospitals And Diagnostics Labs, Pharmaceutical And Biotechnological Industries, Others in the Global Sterility Production Isolator Market:

Class III isolators, on the other hand, offer a higher level of protection and are used in environments where the risk of contamination is significantly higher. These isolators are completely sealed and provide a physical barrier between the operator and the product. They are equipped with advanced filtration systems and are designed to handle high-risk agents, including hazardous chemicals and infectious materials. Class III isolators are commonly used in applications such as vaccine production, handling of cytotoxic drugs, and research involving highly pathogenic microorganisms. They are essential in ensuring the safety of both the product and the operator in high-risk environments.

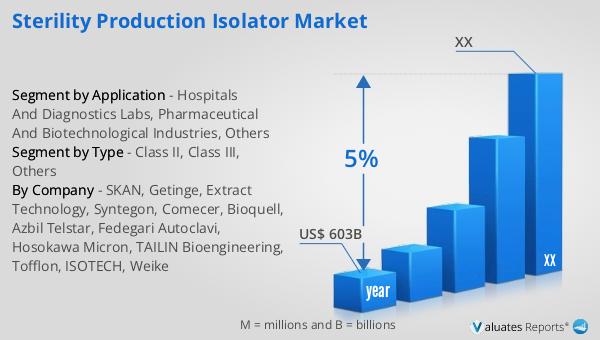

Global Sterility Production Isolator Market Outlook:

In addition to Class II and Class III isolators, there are other types of isolators that are used in specific applications. These include flexible film isolators, which are lightweight and portable, making them ideal for use in field settings or temporary installations. They are commonly used in applications such as sterility testing and small-scale production. Another type of isolator is the rigid wall isolator, which is designed for permanent installations and offers a high level of protection and durability. These isolators are used in applications such as large-scale pharmaceutical production and research laboratories. Overall, the choice of isolator depends on the specific requirements of the application, including the level of protection needed, the type of materials being handled, and the regulatory standards that must be met.

| Report Metric | Details |

| Report Name | Sterility Production Isolator Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | SKAN, Getinge, Extract Technology, Syntegon, Comecer, Bioquell, Azbil Telstar, Fedegari Autoclavi, Hosokawa Micron, TAILIN Bioengineering, Tofflon, ISOTECH, Weike |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |