What is Global Phos-Copper-Tin Filler Metal Market?

The Global Phos-Copper-Tin Filler Metal Market is a specialized segment within the broader metal industry, focusing on the production and distribution of filler metals composed primarily of phosphorus, copper, and tin. These metals are essential in various industrial applications due to their unique properties, such as excellent corrosion resistance, high thermal and electrical conductivity, and good mechanical strength. The market for these filler metals is driven by their widespread use in industries like electronics, automotive, and construction, where they serve as critical components in soldering and brazing processes. The demand for Phos-Copper-Tin filler metals is influenced by factors such as technological advancements, the growth of end-user industries, and the increasing need for efficient and reliable joining solutions. As industries continue to evolve and seek more sustainable and efficient manufacturing processes, the role of these filler metals becomes increasingly significant, making the Global Phos-Copper-Tin Filler Metal Market a vital area of focus for manufacturers and researchers alike.

Rod Shaped, Ring Shaped, Filamentous Shaped in the Global Phos-Copper-Tin Filler Metal Market:

In the Global Phos-Copper-Tin Filler Metal Market, the shape of the filler metal plays a crucial role in determining its application and effectiveness. Rod-shaped filler metals are commonly used in manual brazing processes. These rods are typically long and cylindrical, making them easy to handle and apply in various industrial settings. The rod shape allows for precise control during the brazing process, ensuring a strong and reliable joint. This shape is particularly favored in applications where manual dexterity and precision are required, such as in the repair and maintenance of machinery and equipment. The rod-shaped filler metals are also versatile, as they can be cut to the desired length, making them suitable for a wide range of applications. Ring-shaped filler metals, on the other hand, are designed for use in automated brazing processes. These rings are pre-formed to fit specific joint configurations, ensuring consistent and uniform application of the filler metal. The ring shape is particularly advantageous in high-volume production environments, where speed and efficiency are critical. By using ring-shaped filler metals, manufacturers can achieve precise and repeatable results, reducing the risk of defects and improving overall product quality. This shape is commonly used in the automotive and aerospace industries, where precision and reliability are paramount. Filamentous-shaped filler metals are another important category within the Global Phos-Copper-Tin Filler Metal Market. These filler metals are characterized by their thin, wire-like form, which allows for easy manipulation and application in intricate and complex joint configurations. The filamentous shape is ideal for applications where flexibility and adaptability are required, such as in the electronics industry. The thin wire form allows for precise control over the amount of filler metal applied, minimizing waste and ensuring a clean and efficient brazing process. This shape is also favored in applications where space is limited, as the thin wire can easily navigate tight and confined spaces. Each of these shapes offers unique advantages and is suited to specific applications within the Global Phos-Copper-Tin Filler Metal Market. The choice of shape depends on factors such as the type of brazing process, the complexity of the joint configuration, and the specific requirements of the end-use application. As industries continue to evolve and demand more efficient and reliable joining solutions, the importance of selecting the appropriate filler metal shape becomes increasingly significant. Manufacturers and researchers in the field are continually exploring new ways to optimize the performance and application of these filler metals, ensuring that they meet the ever-changing needs of the market.

Electric Machinery, Electrical Switch, Refrigeration, Others in the Global Phos-Copper-Tin Filler Metal Market:

The Global Phos-Copper-Tin Filler Metal Market finds extensive usage across various industries, including electric machinery, electrical switches, refrigeration, and others. In the electric machinery sector, these filler metals are crucial for ensuring reliable and efficient connections between different components. The high thermal and electrical conductivity of Phos-Copper-Tin filler metals makes them ideal for use in electric motors, transformers, and generators, where efficient heat dissipation and electrical conductivity are essential. By providing strong and durable joints, these filler metals help enhance the performance and longevity of electric machinery, reducing the risk of failures and downtime. In the electrical switch industry, Phos-Copper-Tin filler metals play a vital role in the manufacturing of switches and circuit breakers. These components require precise and reliable connections to ensure safe and efficient operation. The excellent mechanical strength and corrosion resistance of these filler metals make them well-suited for use in electrical switches, where they help maintain the integrity and reliability of the connections over time. By ensuring strong and durable joints, these filler metals contribute to the overall safety and performance of electrical systems. The refrigeration industry also relies heavily on Phos-Copper-Tin filler metals for the assembly and maintenance of refrigeration systems. These systems require efficient and reliable connections to ensure optimal performance and energy efficiency. The high thermal conductivity of these filler metals makes them ideal for use in refrigeration systems, where they help facilitate efficient heat transfer and minimize energy loss. By providing strong and durable joints, these filler metals help enhance the performance and longevity of refrigeration systems, reducing the risk of leaks and failures. Beyond these specific industries, Phos-Copper-Tin filler metals are also used in a variety of other applications, including plumbing, HVAC systems, and metal fabrication. In plumbing, these filler metals are used to join copper pipes and fittings, ensuring leak-free and reliable connections. In HVAC systems, they are used to assemble and maintain components such as heat exchangers and condensers, where efficient heat transfer is critical. In metal fabrication, these filler metals are used to join different metal components, providing strong and durable joints that enhance the overall structural integrity of the finished product. Overall, the Global Phos-Copper-Tin Filler Metal Market plays a crucial role in a wide range of industries, providing essential joining solutions that enhance the performance, reliability, and efficiency of various systems and components. As industries continue to evolve and demand more efficient and reliable joining solutions, the importance of these filler metals is expected to grow, driving further innovation and development in the market.

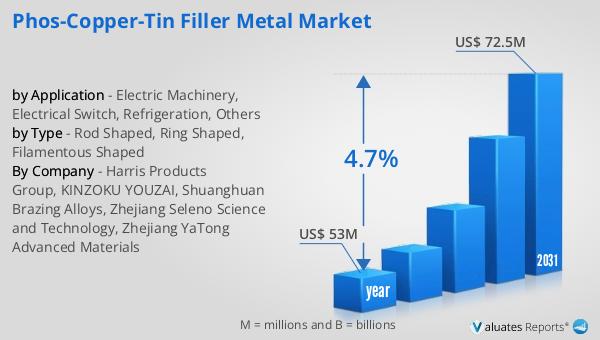

Global Phos-Copper-Tin Filler Metal Market Outlook:

The worldwide market for Phos-Copper-Tin Filler Metal was estimated to be worth $53 million in 2024. It is anticipated to expand to a revised valuation of $72.5 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.7% over the forecast period. This growth trajectory underscores the increasing demand for Phos-Copper-Tin filler metals across various industries, driven by their unique properties and versatile applications. The projected expansion of the market highlights the growing recognition of these filler metals as essential components in industrial processes, particularly in sectors such as electronics, automotive, and construction. As industries continue to seek more efficient and reliable joining solutions, the demand for Phos-Copper-Tin filler metals is expected to rise, contributing to the overall growth of the market. This positive outlook reflects the ongoing advancements in technology and the increasing focus on sustainability and efficiency in manufacturing processes. The anticipated growth of the market also presents significant opportunities for manufacturers and researchers to explore new applications and optimize the performance of these filler metals, ensuring they meet the evolving needs of the market.

| Report Metric | Details |

| Report Name | Phos-Copper-Tin Filler Metal Market |

| Accounted market size in year | US$ 53 million |

| Forecasted market size in 2031 | US$ 72.5 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Harris Products Group, KINZOKU YOUZAI, Shuanghuan Brazing Alloys, Zhejiang Seleno Science and Technology, Zhejiang YaTong Advanced Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |