What is Global Non Contact Articulated Arm Measuring Machine Market?

The Global Non Contact Articulated Arm Measuring Machine Market refers to a specialized segment within the broader field of precision measurement technology. These machines are designed to measure the physical geometrical characteristics of an object without making physical contact, using articulated arms that can move freely in three-dimensional space. This technology is particularly valuable in industries where precision and accuracy are paramount, such as aerospace, automotive, and electronics. The articulated arm allows for flexibility and ease of use, enabling operators to measure complex shapes and surfaces that might be difficult to assess with traditional contact-based measuring tools. The non-contact aspect of these machines is crucial for delicate or soft materials that could be damaged by physical contact. As industries continue to demand higher precision and efficiency, the market for these advanced measuring machines is expected to grow, driven by technological advancements and the increasing complexity of manufactured components. The ability to provide accurate measurements without physical contact not only enhances the quality control processes but also reduces the risk of damaging sensitive parts, making these machines an essential tool in modern manufacturing environments.

Measuring Range up to 3 Meters, Measuring Range 3-5 Meters, Measuring Range above 5 Meters in the Global Non Contact Articulated Arm Measuring Machine Market:

The Global Non Contact Articulated Arm Measuring Machine Market can be segmented based on the measuring range, which is a critical factor in determining the suitability of a machine for specific applications. Machines with a measuring range of up to 3 meters are typically used for smaller components or assemblies. These machines are ideal for industries where precision is required on a smaller scale, such as in the electronics industry, where components are often compact and require meticulous measurement. The compact size of these machines makes them highly portable and easy to maneuver, allowing for quick and efficient measurements in confined spaces. On the other hand, machines with a measuring range of 3 to 5 meters are suited for medium-sized components. This range is particularly useful in the automotive industry, where parts such as car doors, panels, and other medium-sized components need to be measured with high accuracy. The flexibility of the articulated arm allows for comprehensive measurement of complex shapes and surfaces, ensuring that all aspects of a component meet the required specifications. For larger components, machines with a measuring range above 5 meters are necessary. These machines are often used in the aerospace industry, where large parts such as wings, fuselages, and other structural components require precise measurement to ensure safety and performance. The ability to measure large components without physical contact is particularly important in this industry, as it reduces the risk of damaging expensive and critical parts. The extended reach of these machines allows for comprehensive measurement of large surfaces, ensuring that all aspects of a component are within the required tolerances. Overall, the choice of measuring range is a crucial consideration for companies looking to invest in non-contact articulated arm measuring machines, as it determines the types of components that can be accurately measured and the industries in which the machines can be effectively utilized.

Aerospace, Automotive, Electronics, Others in the Global Non Contact Articulated Arm Measuring Machine Market:

The Global Non Contact Articulated Arm Measuring Machine Market finds extensive usage across various industries, each with its unique requirements and challenges. In the aerospace industry, these machines are indispensable for ensuring the precision and safety of aircraft components. The ability to measure large and complex parts such as wings, fuselages, and engine components without physical contact is crucial, as it prevents potential damage to expensive and critical parts. The high accuracy and flexibility of these machines allow for comprehensive measurement of intricate shapes and surfaces, ensuring that all components meet stringent safety and performance standards. In the automotive industry, non-contact articulated arm measuring machines are used to ensure the quality and precision of various components, from small parts like gears and bearings to larger assemblies such as car doors and panels. The ability to measure complex shapes and surfaces with high accuracy is essential for maintaining the quality and performance of automotive components, which are subject to rigorous testing and quality control processes. In the electronics industry, these machines are used to measure small and delicate components, where precision is paramount. The non-contact aspect of these machines is particularly important in this industry, as it prevents damage to sensitive components that could be caused by physical contact. The flexibility and accuracy of these machines allow for precise measurement of intricate shapes and surfaces, ensuring that all components meet the required specifications. Beyond these industries, non-contact articulated arm measuring machines are also used in other sectors such as manufacturing, where precision and accuracy are critical for ensuring the quality and performance of various components and assemblies. The versatility and flexibility of these machines make them an essential tool in modern manufacturing environments, where the demand for high precision and efficiency continues to grow.

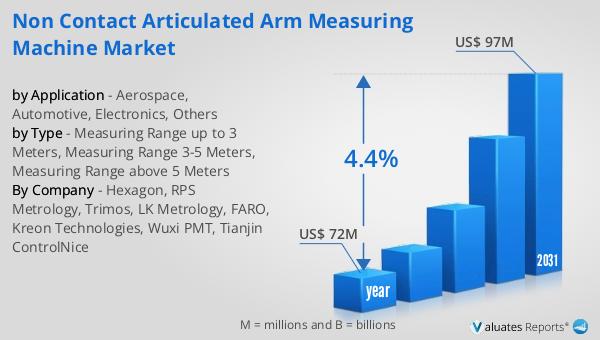

Global Non Contact Articulated Arm Measuring Machine Market Outlook:

The global market for Non Contact Articulated Arm Measuring Machines was valued at approximately $72 million in 2024. This market is anticipated to expand, reaching an estimated size of $97 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.4% over the forecast period. This steady increase in market size reflects the growing demand for precision measurement tools across various industries. As technology advances and industries continue to evolve, the need for accurate and efficient measurement solutions becomes increasingly important. Non-contact articulated arm measuring machines offer a unique combination of flexibility, accuracy, and non-intrusiveness, making them an attractive option for industries that require precise measurement of complex shapes and surfaces. The projected growth in this market is driven by several factors, including the increasing complexity of manufactured components, the need for higher precision in quality control processes, and the growing adoption of advanced measurement technologies in emerging markets. As industries continue to prioritize precision and efficiency, the demand for non-contact articulated arm measuring machines is expected to rise, driving further growth in this market.

| Report Metric | Details |

| Report Name | Non Contact Articulated Arm Measuring Machine Market |

| Accounted market size in year | US$ 72 million |

| Forecasted market size in 2031 | US$ 97 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hexagon, RPS Metrology, Trimos, LK Metrology, FARO, Kreon Technologies, Wuxi PMT, Tianjin ControlNice |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |