What is Global Moving Column High Speed Gantry Machining Center Market?

The Global Moving Column High Speed Gantry Machining Center Market is a specialized segment within the broader machine tool industry, focusing on advanced machining centers that feature a moving column design. These machines are engineered to deliver high-speed, precise, and efficient machining operations, making them ideal for industries that require intricate and large-scale component manufacturing. The moving column design allows for greater flexibility and efficiency, as the column itself moves along the gantry, enabling the machining of large parts without the need to reposition them. This design is particularly beneficial for industries such as aerospace, automotive, and shipbuilding, where the production of large, complex parts is common. The market for these machining centers is driven by the demand for high precision and efficiency in manufacturing processes, as well as the need for machines that can handle large workpieces with ease. As industries continue to evolve and demand more sophisticated manufacturing solutions, the Global Moving Column High Speed Gantry Machining Center Market is expected to grow, offering advanced solutions to meet these needs.

Single Spindle, Dual Spindle, Multiple Spindles in the Global Moving Column High Speed Gantry Machining Center Market:

In the Global Moving Column High Speed Gantry Machining Center Market, the configuration of spindles plays a crucial role in determining the machine's capabilities and efficiency. Single spindle machines are typically used for operations that require high precision and are suitable for smaller production runs. These machines are often favored in industries where the focus is on achieving the highest level of accuracy and surface finish, such as in the aerospace and medical device sectors. The single spindle design allows for concentrated power and precision, making it ideal for detailed and intricate work. On the other hand, dual spindle machines offer a balance between precision and productivity. By having two spindles, these machines can perform simultaneous operations, effectively doubling the output without compromising on quality. This configuration is particularly advantageous in the automotive industry, where the demand for high-volume production is coupled with the need for precision. Dual spindle machines can handle complex parts with ease, reducing cycle times and increasing overall efficiency. Multiple spindle machines take this concept further by incorporating three or more spindles, significantly boosting production capabilities. These machines are designed for high-volume manufacturing environments where speed and efficiency are paramount. Industries such as shipbuilding and heavy machinery manufacturing benefit from multiple spindle machines, as they can produce large quantities of parts in a shorter time frame. The ability to perform multiple operations simultaneously not only increases productivity but also reduces labor costs and machine downtime. Each spindle configuration offers unique advantages, and the choice between single, dual, or multiple spindles depends on the specific needs of the industry and the nature of the production process. As technology advances, the versatility and capabilities of these machines continue to expand, providing manufacturers with a range of options to optimize their operations.

Automobile Industry, Ship Industry, Aerospace Industry, Others in the Global Moving Column High Speed Gantry Machining Center Market:

The Global Moving Column High Speed Gantry Machining Center Market finds extensive applications across various industries, each benefiting from the unique capabilities of these advanced machines. In the automobile industry, these machining centers are used to manufacture a wide range of components, from engine blocks to transmission housings. The high-speed and precision capabilities of these machines ensure that automotive parts are produced with the highest quality standards, meeting the stringent requirements of the industry. The ability to handle large workpieces and perform complex machining operations in a single setup reduces production time and costs, making these machines an invaluable asset in automotive manufacturing. In the ship industry, the demand for large-scale, high-precision components is ever-present. Moving column high speed gantry machining centers are ideal for producing parts such as propellers, hull sections, and other critical components that require precise machining. The flexibility and efficiency of these machines allow shipbuilders to produce large parts with intricate details, ensuring the structural integrity and performance of the vessels. The aerospace industry also relies heavily on these machining centers for the production of aircraft components. The need for lightweight, high-strength materials in aerospace manufacturing necessitates the use of advanced machining technologies. Moving column high speed gantry machining centers are capable of machining complex geometries with high precision, making them essential for producing components such as wing spars, fuselage sections, and engine parts. The ability to work with a variety of materials, including aluminum, titanium, and composites, further enhances their utility in the aerospace sector. Beyond these industries, moving column high speed gantry machining centers are also used in other sectors such as energy, defense, and heavy equipment manufacturing. The versatility and efficiency of these machines make them suitable for a wide range of applications, from producing turbine blades to manufacturing military vehicle components. As industries continue to demand higher precision and efficiency in their manufacturing processes, the role of moving column high speed gantry machining centers is expected to grow, providing advanced solutions to meet these evolving needs.

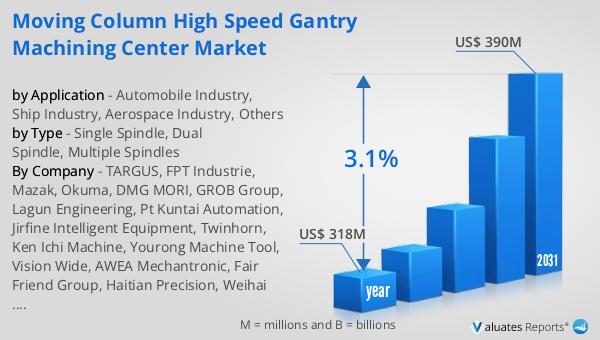

Global Moving Column High Speed Gantry Machining Center Market Outlook:

The global market for Moving Column High Speed Gantry Machining Centers was valued at approximately $318 million in 2024. This market is anticipated to expand, reaching an estimated size of $390 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 3.1% over the forecast period. The steady increase in market size underscores the rising demand for these advanced machining centers across various industries. The growth is driven by the need for high precision, efficiency, and the ability to handle large workpieces in manufacturing processes. As industries such as automotive, aerospace, and shipbuilding continue to evolve, the demand for sophisticated machining solutions is expected to rise, contributing to the market's expansion. The moving column design of these machining centers offers significant advantages in terms of flexibility and efficiency, making them an attractive option for manufacturers looking to optimize their operations. The projected growth in the market size indicates a positive outlook for the industry, with opportunities for innovation and development in machining technologies. As manufacturers seek to enhance their production capabilities and meet the demands of modern manufacturing, the Global Moving Column High Speed Gantry Machining Center Market is poised for continued growth and advancement.

| Report Metric | Details |

| Report Name | Moving Column High Speed Gantry Machining Center Market |

| Accounted market size in year | US$ 318 million |

| Forecasted market size in 2031 | US$ 390 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TARGUS, FPT Industrie, Mazak, Okuma, DMG MORI, GROB Group, Lagun Engineering, Pt Kuntai Automation, Jirfine Intelligent Equipment, Twinhorn, Ken Ichi Machine, Yourong Machine Tool, Vision Wide, AWEA Mechantronic, Fair Friend Group, Haitian Precision, Weihai Huadong Automation, TD-Group, GRENTEK MECHATRONICS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |