What is Global Medical Resin Market?

The Global Medical Resin Market is a crucial segment within the broader medical industry, focusing on the production and application of specialized resins used in various medical devices and equipment. These resins are essential due to their unique properties, such as biocompatibility, durability, and resistance to chemicals and sterilization processes. Medical resins are used in a wide range of applications, from diagnostic equipment to prosthetic devices, making them indispensable in modern healthcare. The market is driven by the increasing demand for advanced medical devices, the growing prevalence of chronic diseases, and the need for more efficient and cost-effective healthcare solutions. Additionally, technological advancements in resin production and processing have led to the development of new materials with enhanced properties, further expanding their applications in the medical field. As healthcare systems worldwide continue to evolve, the demand for high-quality medical resins is expected to grow, making this market a vital component of the global healthcare industry. The Global Medical Resin Market not only supports the development of innovative medical technologies but also plays a significant role in improving patient outcomes and enhancing the overall quality of care.

Low Density Polyethylene (LDPE), High Density Polyethylene (HDPE) in the Global Medical Resin Market:

Low Density Polyethylene (LDPE) and High Density Polyethylene (HDPE) are two types of polyethylene that play significant roles in the Global Medical Resin Market. LDPE is known for its flexibility, transparency, and resistance to impact, making it an ideal material for applications that require a certain degree of pliability and toughness. In the medical field, LDPE is commonly used in the production of squeeze bottles, tubing, and other flexible containers. Its ability to withstand sterilization processes without degrading makes it a preferred choice for disposable medical devices. On the other hand, HDPE is characterized by its high strength-to-density ratio, making it a more rigid and durable material compared to LDPE. This property makes HDPE suitable for applications that require sturdiness and resistance to wear and tear, such as in the manufacturing of surgical trays, containers, and other medical equipment that need to maintain their shape and integrity under stress. Both LDPE and HDPE are valued for their chemical resistance, which is crucial in medical applications where exposure to various substances is common. Furthermore, these materials are lightweight, which is an important consideration in the design and manufacturing of medical devices that need to be easily handled and transported. The use of LDPE and HDPE in the medical industry is also driven by their cost-effectiveness and ease of processing, allowing manufacturers to produce high-quality medical products at a lower cost. As the demand for advanced medical devices continues to grow, the role of LDPE and HDPE in the Global Medical Resin Market is expected to expand, driven by ongoing innovations in material science and processing technologies. These advancements are likely to lead to the development of new polyethylene-based materials with enhanced properties, further broadening their applications in the medical field. The versatility and adaptability of LDPE and HDPE make them indispensable components of the Global Medical Resin Market, supporting the development of innovative medical technologies and contributing to the improvement of healthcare outcomes worldwide.

Diagnostic Equipment, Disposable and Reusable Devices, Medical Electronics, Orthopedic and Prosthetic Devices, Others in the Global Medical Resin Market:

The Global Medical Resin Market finds extensive usage across various areas, including diagnostic equipment, disposable and reusable devices, medical electronics, orthopedic and prosthetic devices, and others. In diagnostic equipment, medical resins are used to manufacture components that require precision and durability, such as housings for imaging devices and parts for laboratory equipment. The biocompatibility and chemical resistance of these resins ensure that they can withstand the rigorous demands of medical diagnostics without compromising performance. In the realm of disposable and reusable devices, medical resins are essential for producing items like syringes, catheters, and surgical instruments. The ability of these resins to endure sterilization processes while maintaining their structural integrity makes them ideal for both single-use and reusable applications. Medical electronics also benefit from the use of medical resins, as they provide the necessary insulation and protection for sensitive electronic components used in devices like pacemakers and monitoring systems. The durability and reliability of these resins ensure that medical electronics can function effectively in various environments, contributing to better patient care. In orthopedic and prosthetic devices, medical resins are used to create lightweight and durable components that enhance patient mobility and comfort. The adaptability of these resins allows for the customization of prosthetic devices to meet individual patient needs, improving their quality of life. Beyond these specific areas, medical resins are also used in a variety of other applications, such as dental devices, wound care products, and drug delivery systems. The versatility and adaptability of medical resins make them a critical component of the Global Medical Resin Market, supporting the development of innovative medical technologies and improving healthcare outcomes across the board. As the demand for advanced medical devices continues to grow, the role of medical resins in these areas is expected to expand, driven by ongoing innovations in material science and processing technologies.

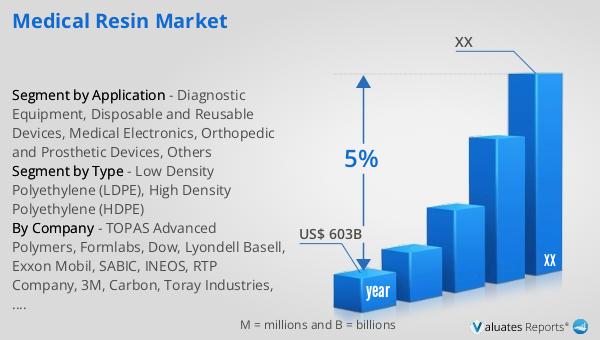

Global Medical Resin Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately USD 603 billion in 2023. This substantial market size underscores the critical role that medical devices play in the healthcare industry, providing essential tools and technologies that enhance patient care and treatment outcomes. The market is anticipated to grow at a compound annual growth rate (CAGR) of 5% over the next six years, reflecting the increasing demand for advanced medical technologies and the continuous evolution of healthcare systems worldwide. This growth is driven by several factors, including the rising prevalence of chronic diseases, an aging global population, and the ongoing development of innovative medical devices that offer improved functionality and efficiency. As healthcare providers strive to deliver better patient outcomes and reduce costs, the demand for high-quality medical devices is expected to rise, further fueling market growth. Additionally, advancements in material science and manufacturing processes are enabling the production of more sophisticated and reliable medical devices, contributing to the expansion of the market. The projected growth of the global medical device market highlights the importance of continued investment in research and development, as well as the need for collaboration between industry stakeholders to address emerging healthcare challenges and meet the evolving needs of patients and healthcare providers.

| Report Metric | Details |

| Report Name | Medical Resin Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | TOPAS Advanced Polymers, Formlabs, Dow, Lyondell Basell, Exxon Mobil, SABIC, INEOS, RTP Company, 3M, Carbon, Toray Industries, Sumitomo Chemical Company, DuPont, Celanese Corporation, Arkema |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |