What is Global Mass Flow Controllers for Photovoltaic Market?

The Global Mass Flow Controllers for Photovoltaic Market is an essential segment within the broader photovoltaic industry, focusing on devices that precisely measure and control the flow of gases and liquids used in the production of solar cells and modules. These controllers are crucial for maintaining the quality and efficiency of photovoltaic products, as they ensure the accurate delivery of materials during various manufacturing processes. The market for these controllers is driven by the increasing demand for renewable energy sources, particularly solar energy, which is seen as a sustainable solution to the world's growing energy needs. As the photovoltaic industry continues to expand, the need for advanced mass flow controllers that can handle the specific requirements of solar cell production becomes more pronounced. These devices are designed to operate under the unique conditions of photovoltaic manufacturing, where precision and reliability are paramount. The market is characterized by technological advancements and innovations aimed at improving the performance and efficiency of mass flow controllers, thereby supporting the overall growth of the photovoltaic sector. As a result, the Global Mass Flow Controllers for Photovoltaic Market plays a vital role in the transition towards cleaner and more sustainable energy solutions.

Gas, Liquid in the Global Mass Flow Controllers for Photovoltaic Market:

In the realm of the Global Mass Flow Controllers for Photovoltaic Market, the differentiation between gas and liquid flow controllers is pivotal, as each serves distinct functions in the photovoltaic manufacturing process. Gas-based mass flow controllers are primarily used in processes like chemical vapor deposition (CVD) and physical vapor deposition (PVD), where precise gas flow is critical for creating thin films on solar cells. These controllers ensure that gases such as silane, hydrogen, and nitrogen are delivered at exact rates, which is crucial for forming the layers that make up photovoltaic cells. The accuracy of gas flow controllers directly impacts the efficiency and quality of the solar cells produced, as even minor deviations can lead to defects or inefficiencies in the final product. On the other hand, liquid-based mass flow controllers are employed in processes that require the precise delivery of liquid chemicals, such as in the etching or cleaning stages of solar cell production. These controllers manage the flow of liquids like acids and solvents, ensuring that they are applied consistently and uniformly across the solar cell surfaces. The precision offered by liquid flow controllers is essential for maintaining the integrity and performance of the photovoltaic cells, as any inconsistencies can compromise their functionality. Both gas and liquid mass flow controllers are integral to the photovoltaic manufacturing process, as they provide the necessary precision and control required to produce high-quality solar cells. The demand for these controllers is driven by the need for more efficient and reliable photovoltaic products, as well as the ongoing advancements in solar technology. As the photovoltaic industry continues to evolve, the role of mass flow controllers in ensuring the quality and efficiency of solar cells becomes increasingly important. Manufacturers are continually seeking ways to enhance the performance of these controllers, incorporating advanced technologies and materials to improve their accuracy and reliability. This focus on innovation is a key driver of growth in the Global Mass Flow Controllers for Photovoltaic Market, as companies strive to meet the demands of an ever-expanding solar energy sector. The interplay between gas and liquid flow controllers highlights the complexity and precision required in photovoltaic manufacturing, underscoring the importance of these devices in the production of sustainable energy solutions.

Thin Film Deposition, Silicon Wafer Preparation, PV Module Manufacturing, Others in the Global Mass Flow Controllers for Photovoltaic Market:

The usage of Global Mass Flow Controllers for Photovoltaic Market in areas such as Thin Film Deposition, Silicon Wafer Preparation, PV Module Manufacturing, and others is crucial for the efficient production of solar energy components. In Thin Film Deposition, mass flow controllers are used to regulate the flow of gases and liquids that form the thin layers on solar cells. This process requires extreme precision, as the thickness and uniformity of the films directly affect the cell's efficiency and performance. Mass flow controllers ensure that the deposition process is consistent, leading to higher quality and more efficient solar cells. In Silicon Wafer Preparation, these controllers manage the flow of chemicals used in cleaning and etching the wafers. The precision offered by mass flow controllers is essential for removing impurities and creating a smooth surface, which is critical for the subsequent layering processes. In PV Module Manufacturing, mass flow controllers are used to control the flow of encapsulants and other materials that protect the solar cells and enhance their durability. The accuracy of these controllers ensures that the materials are applied evenly, preventing defects and improving the longevity of the modules. Additionally, mass flow controllers are used in other areas of photovoltaic manufacturing, such as doping and annealing, where precise control of gas and liquid flows is necessary to achieve the desired electrical properties of the solar cells. The versatility and precision of mass flow controllers make them indispensable in the photovoltaic industry, as they contribute to the production of high-quality and efficient solar energy components. As the demand for solar energy continues to grow, the role of mass flow controllers in ensuring the quality and efficiency of photovoltaic products becomes increasingly important. Manufacturers are continually seeking ways to improve the performance of these controllers, incorporating advanced technologies and materials to enhance their accuracy and reliability. This focus on innovation is a key driver of growth in the Global Mass Flow Controllers for Photovoltaic Market, as companies strive to meet the demands of an ever-expanding solar energy sector. The use of mass flow controllers in various stages of photovoltaic manufacturing underscores their importance in the production of sustainable energy solutions, highlighting their role in the transition towards cleaner and more efficient energy sources.

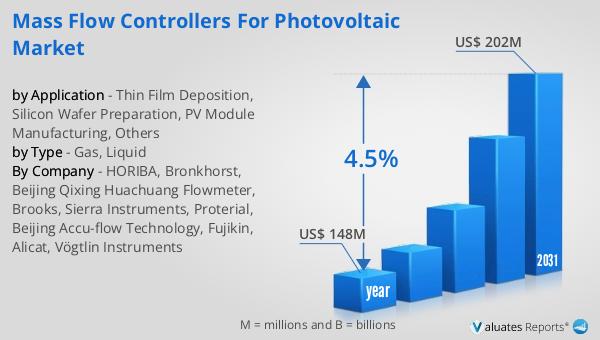

Global Mass Flow Controllers for Photovoltaic Market Outlook:

In 2024, the global market for Mass Flow Controllers specifically tailored for the Photovoltaic sector was valued at approximately $148 million. This market is anticipated to grow significantly, reaching an estimated value of $202 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.5% over the forecast period. This upward trend is indicative of the increasing demand for precision and efficiency in the photovoltaic manufacturing process, driven by the global shift towards renewable energy sources. The growth in this market can be attributed to several factors, including technological advancements in mass flow controller design and the expanding photovoltaic industry. As solar energy becomes a more prominent component of the global energy mix, the need for high-quality photovoltaic products becomes more critical. Mass flow controllers play a vital role in ensuring the precision and reliability of these products, making them an essential component of the photovoltaic manufacturing process. The projected growth in the market for mass flow controllers reflects the ongoing efforts to improve the efficiency and performance of solar energy systems, as well as the increasing investment in renewable energy technologies. This growth is expected to continue as the demand for sustainable energy solutions rises, highlighting the importance of mass flow controllers in the transition towards a cleaner and more sustainable energy future.

| Report Metric | Details |

| Report Name | Mass Flow Controllers for Photovoltaic Market |

| Accounted market size in year | US$ 148 million |

| Forecasted market size in 2031 | US$ 202 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HORIBA, Bronkhorst, Beijing Qixing Huachuang Flowmeter, Brooks, Sierra Instruments, Proterial, Beijing Accu-flow Technology, Fujikin, Alicat, Vögtlin Instruments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |