What is Global Liquid Source Vaporizers Market?

The Global Liquid Source Vaporizers Market is a specialized segment within the broader industrial equipment sector, focusing on devices that convert liquid precursors into vapor for various applications. These vaporizers are crucial in industries where precise vapor delivery is essential, such as semiconductor manufacturing, solar panel production, and other high-tech fields. The market is driven by the increasing demand for advanced electronic devices and renewable energy solutions, which require sophisticated manufacturing processes. Liquid source vaporizers offer a controlled and efficient method for delivering chemical vapors, ensuring high-quality production standards. The market is characterized by technological advancements, with manufacturers continuously innovating to improve vaporization efficiency and reduce operational costs. As industries strive for greater precision and efficiency, the demand for liquid source vaporizers is expected to grow, making it a dynamic and evolving market. The market's growth is also supported by the expansion of the semiconductor and solar industries, particularly in regions like Asia-Pacific, where manufacturing activities are concentrated. Overall, the Global Liquid Source Vaporizers Market plays a vital role in supporting the technological advancements and production capabilities of various high-tech industries.

Direct Injection, Mixed Injection, Others in the Global Liquid Source Vaporizers Market:

In the Global Liquid Source Vaporizers Market, different injection methods are employed to convert liquid precursors into vapor, each with its unique advantages and applications. Direct Injection is the most prevalent method, accounting for over 75% of the market share. This technique involves injecting the liquid precursor directly into a heated chamber, where it is rapidly vaporized. The direct injection method is favored for its simplicity and efficiency, providing precise control over the vaporization process. It is particularly useful in applications requiring high purity and consistency, such as semiconductor manufacturing. Mixed Injection, on the other hand, combines the liquid precursor with a carrier gas before injection. This method allows for better control over the vapor concentration and distribution, making it suitable for applications where uniformity is critical. Mixed Injection is often used in processes where multiple precursors need to be vaporized simultaneously, ensuring a homogeneous mixture. Other methods in the market include bubbler systems and flash vaporizers, which offer alternative approaches to vaporization. Bubbler systems involve passing a carrier gas through a liquid precursor, picking up vapor as it bubbles through the liquid. This method is advantageous for its simplicity and ability to handle a wide range of precursor viscosities. Flash vaporizers, meanwhile, rapidly heat the liquid precursor to its boiling point, creating vapor almost instantaneously. This method is ideal for applications requiring rapid vaporization and minimal thermal decomposition. Each of these methods has its own set of benefits and limitations, and the choice of method depends on the specific requirements of the application, such as the type of precursor, desired vapor flow rate, and process conditions. As the Global Liquid Source Vaporizers Market continues to evolve, manufacturers are exploring new technologies and techniques to enhance vaporization efficiency and meet the diverse needs of their customers. The ongoing research and development efforts in this field are expected to lead to further innovations, expanding the range of applications and improving the performance of liquid source vaporizers.

Semiconductor, Solar Industry, Industrial, Others in the Global Liquid Source Vaporizers Market:

The Global Liquid Source Vaporizers Market finds extensive usage across several key industries, each benefiting from the precise vapor delivery these devices offer. In the semiconductor industry, liquid source vaporizers are essential for processes like chemical vapor deposition (CVD) and atomic layer deposition (ALD), where they ensure the uniform application of thin films on semiconductor wafers. The precision and control offered by these vaporizers are crucial for producing high-performance semiconductor devices, which are foundational to modern electronics. The solar industry also relies heavily on liquid source vaporizers, particularly in the production of photovoltaic cells. These vaporizers enable the deposition of thin films of materials like cadmium telluride and copper indium gallium selenide, which are critical for the efficiency and performance of solar panels. By ensuring uniform and high-quality film deposition, liquid source vaporizers contribute to the advancement of solar technology and the broader adoption of renewable energy. In industrial applications, these vaporizers are used in processes that require precise vapor delivery, such as coating, surface treatment, and chemical synthesis. The ability to control vapor flow and composition is vital for achieving the desired material properties and process outcomes. Other industries, including pharmaceuticals and aerospace, also utilize liquid source vaporizers for specialized applications, benefiting from their ability to deliver precise and consistent vapor streams. As industries continue to advance and demand higher precision and efficiency, the role of liquid source vaporizers is expected to grow, supporting innovation and production across various sectors.

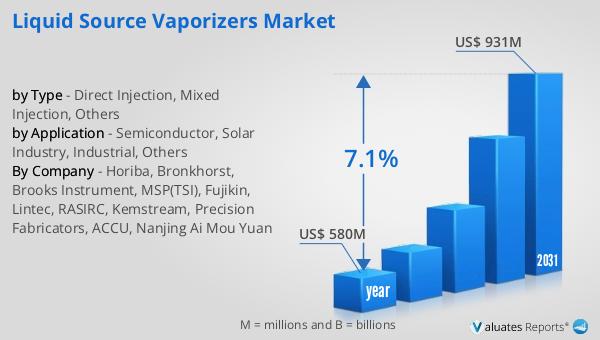

Global Liquid Source Vaporizers Market Outlook:

The global market for Liquid Source Vaporizers was valued at approximately $580 million in 2024 and is anticipated to expand to a revised size of around $931 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.1% over the forecast period. The market is dominated by the top three manufacturers, who collectively hold a significant share of over 80%. The Asia-Pacific region emerges as the largest consumer market, accounting for about 77% of the total market share, followed by North America and Europe, which hold approximately 15% and 6% of the market share, respectively. Direct Injection stands out as the most prominent type within the market, capturing a substantial share of over 75%. This method's dominance is attributed to its efficiency and precision, making it the preferred choice for many applications. The market dynamics are influenced by the growing demand for advanced manufacturing processes in industries such as semiconductors and solar energy, where liquid source vaporizers play a critical role. As these industries continue to expand, particularly in the Asia-Pacific region, the demand for liquid source vaporizers is expected to rise, driving market growth and innovation.

| Report Metric | Details |

| Report Name | Liquid Source Vaporizers Market |

| Accounted market size in year | US$ 580 million |

| Forecasted market size in 2031 | US$ 931 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Horiba, Bronkhorst, Brooks Instrument, MSP(TSI), Fujikin, Lintec, RASIRC, Kemstream, Precision Fabricators, ACCU, Nanjing Ai Mou Yuan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |