What is Global High Resolution Ultrasonic Level Sensor Market?

The Global High Resolution Ultrasonic Level Sensor Market is a specialized segment within the broader sensor industry, focusing on devices that use ultrasonic waves to measure the level of liquids or solids within a container or environment. These sensors are highly valued for their precision and reliability, making them essential in various industrial applications. They work by emitting ultrasonic pulses and measuring the time it takes for the echo to return, which is then used to calculate the distance to the surface of the material being measured. This technology is particularly useful in situations where contact with the material is undesirable or impractical, such as in corrosive or hazardous environments. The market for these sensors is driven by the increasing demand for automation and control in industries like oil and gas, chemicals, and food and beverage, where accurate level measurement is crucial for operational efficiency and safety. As industries continue to evolve and adopt more sophisticated technologies, the demand for high-resolution ultrasonic level sensors is expected to grow, offering opportunities for innovation and development in sensor technology.

Point Type, Continuous Type in the Global High Resolution Ultrasonic Level Sensor Market:

In the Global High Resolution Ultrasonic Level Sensor Market, sensors are primarily categorized into two types: Point Type and Continuous Type. Point Type sensors are designed to detect the presence or absence of a material at a specific point. They are often used in applications where it is necessary to know whether a tank is full or empty, or to detect the presence of a material at a particular level. These sensors are typically used in applications where precise level measurement is not critical, but where it is important to know when a certain level has been reached. On the other hand, Continuous Type sensors provide ongoing level measurement, offering real-time data on the level of material within a container. These sensors are crucial in applications where maintaining a specific level is important for process control, such as in chemical processing or water treatment facilities. Continuous Type sensors are often used in conjunction with control systems to automate processes and ensure that levels remain within desired parameters. Both types of sensors have their own advantages and are chosen based on the specific needs of the application. Point Type sensors are generally more cost-effective and simpler to install, making them a popular choice for basic level detection needs. Continuous Type sensors, while more complex and expensive, offer greater precision and control, making them ideal for applications where accuracy is paramount. The choice between Point Type and Continuous Type sensors often depends on factors such as the nature of the material being measured, the environment in which the sensor will be used, and the level of precision required. In industries where safety and efficiency are critical, such as oil and gas or chemical processing, the benefits of Continuous Type sensors often outweigh the higher cost, as they provide the data needed to optimize processes and prevent accidents. As technology continues to advance, the capabilities of both Point Type and Continuous Type sensors are expected to improve, offering even greater accuracy and reliability in level measurement.

Petroleum, Chemical, Food, Others in the Global High Resolution Ultrasonic Level Sensor Market:

The Global High Resolution Ultrasonic Level Sensor Market finds extensive usage across various industries, including petroleum, chemical, food, and others, due to its ability to provide accurate and reliable level measurements. In the petroleum industry, these sensors are used to monitor the levels of crude oil, refined products, and other liquids in storage tanks and pipelines. Accurate level measurement is crucial in this industry to prevent overflows, ensure efficient storage and transportation, and maintain safety standards. In the chemical industry, ultrasonic level sensors are used to measure the levels of various chemicals in tanks and reactors. These sensors help in maintaining the correct chemical ratios and preventing spills or leaks, which can be hazardous. The food industry also benefits from the use of ultrasonic level sensors, as they are used to measure the levels of ingredients and finished products in storage tanks and processing equipment. These sensors help ensure that production processes run smoothly and that products meet quality standards. Additionally, ultrasonic level sensors are used in other industries such as water treatment, pharmaceuticals, and manufacturing, where accurate level measurement is essential for process control and efficiency. The versatility and reliability of ultrasonic level sensors make them an indispensable tool in a wide range of applications, helping industries improve safety, efficiency, and product quality.

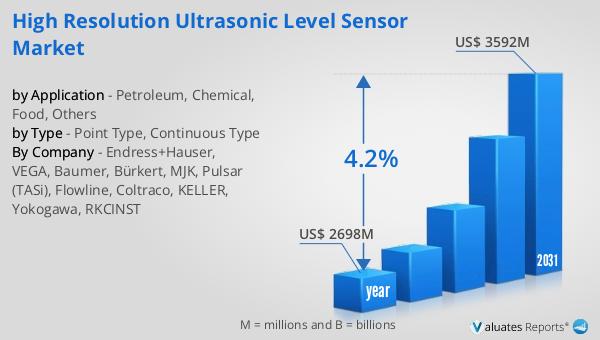

Global High Resolution Ultrasonic Level Sensor Market Outlook:

The global market for High Resolution Ultrasonic Level Sensors was valued at $2,698 million in 2024, and it is anticipated to grow to a revised size of $3,592 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.2% during the forecast period. This growth is indicative of the increasing demand for precise and reliable level measurement solutions across various industries. As industries continue to prioritize automation and efficiency, the need for advanced sensor technologies like high-resolution ultrasonic level sensors is expected to rise. These sensors offer significant advantages in terms of accuracy, reliability, and ease of use, making them an attractive option for industries looking to optimize their processes and improve safety standards. The projected growth of the market also suggests that there will be opportunities for innovation and development in sensor technology, as manufacturers strive to meet the evolving needs of their customers. As the market continues to expand, it is likely that we will see new applications and advancements in ultrasonic level sensor technology, further driving the growth of this market.

| Report Metric | Details |

| Report Name | High Resolution Ultrasonic Level Sensor Market |

| Accounted market size in year | US$ 2698 million |

| Forecasted market size in 2031 | US$ 3592 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Endress+Hauser, VEGA, Baumer, Bürkert, MJK, Pulsar (TASi), Flowline, Coltraco, KELLER, Yokogawa, RKCINST |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |