What is Global Fully Automatic Spin Etcher Market?

The Global Fully Automatic Spin Etcher Market is a specialized segment within the semiconductor manufacturing industry, focusing on equipment used for etching processes. Spin etchers are critical in the fabrication of semiconductor devices, as they enable precise and uniform etching of materials on wafers. These machines are fully automated, meaning they require minimal human intervention, which enhances efficiency and reduces the likelihood of errors. The automation aspect is particularly important in maintaining the high precision required in semiconductor manufacturing. The market for these machines is driven by the increasing demand for semiconductors across various industries, including electronics, automotive, and telecommunications. As technology advances, the need for smaller and more efficient semiconductor devices grows, further fueling the demand for advanced etching equipment. The Global Fully Automatic Spin Etcher Market is characterized by continuous innovation, with manufacturers striving to improve the speed, accuracy, and reliability of their machines. This market is also influenced by the broader trends in the semiconductor industry, such as the shift towards smaller node sizes and the increasing complexity of semiconductor devices. Overall, the Global Fully Automatic Spin Etcher Market plays a crucial role in the advancement of semiconductor technology.

Single Wafer Spin Processor, Multi Wafer Spin Processor in the Global Fully Automatic Spin Etcher Market:

In the realm of the Global Fully Automatic Spin Etcher Market, two primary types of spin processors are utilized: Single Wafer Spin Processors and Multi Wafer Spin Processors. Single Wafer Spin Processors are designed to handle one wafer at a time, providing a high degree of precision and control over the etching process. This type of processor is particularly beneficial for applications requiring meticulous attention to detail, such as in the production of high-performance semiconductor devices. The single wafer approach allows for individualized treatment of each wafer, ensuring uniformity and consistency in the etching process. This is crucial in maintaining the quality and performance of the final semiconductor products. On the other hand, Multi Wafer Spin Processors are capable of handling multiple wafers simultaneously, significantly increasing throughput and efficiency. This type of processor is ideal for high-volume production environments where speed and efficiency are paramount. Multi Wafer Spin Processors are designed to optimize the etching process by processing several wafers in parallel, thereby reducing the overall processing time. However, this approach may require more sophisticated control systems to ensure uniformity across all wafers being processed. Both types of spin processors have their unique advantages and are chosen based on the specific requirements of the manufacturing process. The choice between Single Wafer and Multi Wafer Spin Processors often depends on factors such as production volume, precision requirements, and cost considerations. In the Global Fully Automatic Spin Etcher Market, manufacturers are continually innovating to enhance the capabilities of both types of processors. Advances in automation, control systems, and materials science are driving improvements in the performance and reliability of spin etchers. As the demand for semiconductors continues to grow, the need for efficient and precise etching solutions becomes increasingly important. The Global Fully Automatic Spin Etcher Market is poised to play a critical role in meeting this demand, providing the tools necessary for the production of advanced semiconductor devices.

6-inch Wafer, 8-inch Wafer, 12-inch Wafer, Others in the Global Fully Automatic Spin Etcher Market:

The Global Fully Automatic Spin Etcher Market finds its application across various wafer sizes, including 6-inch, 8-inch, and 12-inch wafers, as well as other sizes. Each wafer size presents unique challenges and opportunities in the etching process. The 6-inch wafer, being one of the smaller sizes, is often used in niche applications or in the production of specialized semiconductor devices. The etching process for 6-inch wafers requires a high degree of precision, as the smaller size can make it more challenging to achieve uniformity across the wafer surface. Fully automatic spin etchers are particularly beneficial in this context, as they provide the precision and control needed to ensure consistent results. The 8-inch wafer is more commonly used in the semiconductor industry and represents a significant portion of the market. The etching process for 8-inch wafers benefits from the automation and efficiency provided by fully automatic spin etchers. These machines are capable of handling the larger surface area of 8-inch wafers while maintaining the precision required for high-quality semiconductor devices. The 12-inch wafer, being the largest of the standard sizes, presents unique challenges in the etching process. The larger surface area requires more sophisticated control systems to ensure uniformity and precision. Fully automatic spin etchers are well-suited to handle these challenges, providing the necessary automation and precision to achieve consistent results. In addition to the standard wafer sizes, the Global Fully Automatic Spin Etcher Market also caters to other sizes, which may be used in specialized applications or emerging technologies. The flexibility and adaptability of fully automatic spin etchers make them ideal for handling a wide range of wafer sizes and applications. As the semiconductor industry continues to evolve, the demand for advanced etching solutions across various wafer sizes is expected to grow. The Global Fully Automatic Spin Etcher Market is well-positioned to meet this demand, providing the tools necessary for the production of high-quality semiconductor devices across a range of applications.

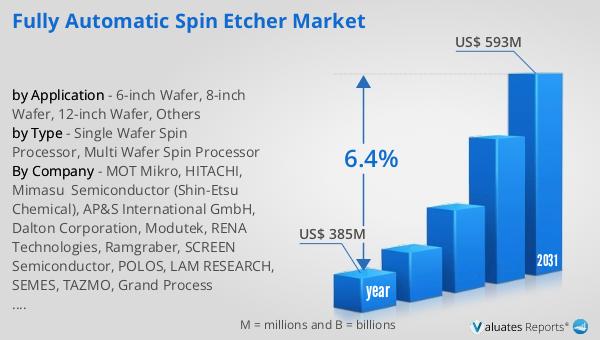

Global Fully Automatic Spin Etcher Market Outlook:

The global market for Fully Automatic Spin Etcher was valued at $385 million in 2024 and is anticipated to expand to a revised size of $593 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.4% over the forecast period. This growth trajectory underscores the increasing demand for advanced etching solutions in the semiconductor industry. The rise in market value is driven by several factors, including the growing need for semiconductors in various sectors such as electronics, automotive, and telecommunications. As these industries continue to evolve and demand more sophisticated semiconductor devices, the need for precise and efficient etching equipment becomes more pronounced. The Fully Automatic Spin Etcher Market is characterized by continuous innovation, with manufacturers striving to enhance the speed, accuracy, and reliability of their machines. This innovation is crucial in meeting the demands of the semiconductor industry, which is constantly pushing the boundaries of technology. The projected growth in the market value also reflects the broader trends in the semiconductor industry, such as the shift towards smaller node sizes and the increasing complexity of semiconductor devices. As the market continues to grow, the Global Fully Automatic Spin Etcher Market is expected to play a pivotal role in the advancement of semiconductor technology, providing the tools necessary for the production of cutting-edge semiconductor devices.

| Report Metric | Details |

| Report Name | Fully Automatic Spin Etcher Market |

| Accounted market size in year | US$ 385 million |

| Forecasted market size in 2031 | US$ 593 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MOT Mikro, HITACHI, Mimasu Semiconductor (Shin-Etsu Chemical), AP&S International GmbH, Dalton Corporation, Modutek, RENA Technologies, Ramgraber, SCREEN Semiconductor, POLOS, LAM RESEARCH, SEMES, TAZMO, Grand Process Technology, GKC Technology, SUZHOU ZHICHENG SEMICONDUCTOR TECHNOLOGY |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |