What is Global Disposable Filtering Facepiece Respirators (FFR) Market?

The Global Disposable Filtering Facepiece Respirators (FFR) Market is a crucial segment within the broader personal protective equipment (PPE) industry. These respirators are designed to protect the wearer from inhaling harmful airborne particles, including dust, fumes, and pathogens. They are disposable, meaning they are intended for single use, which ensures a high level of hygiene and reduces the risk of contamination. The market for these respirators has seen significant growth due to increasing awareness about occupational safety and health, particularly in industries where workers are exposed to hazardous environments. The COVID-19 pandemic further accelerated demand, as healthcare professionals and the general public sought effective protection against the virus. The market is characterized by a variety of products that cater to different filtration needs and standards, such as N95, P100, and R95, each offering varying levels of protection. Manufacturers are continually innovating to improve comfort, fit, and filtration efficiency, which are critical factors influencing consumer choice. The market is also influenced by regulatory standards and guidelines, which vary across regions, impacting the design and distribution of these products. Overall, the Global Disposable FFR Market plays a vital role in safeguarding health across multiple sectors.

N Class, P Class, R Class in the Global Disposable Filtering Facepiece Respirators (FFR) Market:

The classification of disposable filtering facepiece respirators into N Class, P Class, and R Class is based on their resistance to oil and their filtration efficiency. The N Class respirators, such as the widely recognized N95, are not resistant to oil. They are designed to filter out at least 95% of airborne particles, making them suitable for environments where oil-based particulates are not present. These respirators are commonly used in healthcare settings, especially during the COVID-19 pandemic, due to their effectiveness in filtering out pathogens. The P Class respirators, including P95 and P100, offer protection against both oil and non-oil based particulates. The P100, for instance, provides a higher level of filtration efficiency, capturing 99.97% of airborne particles. This makes them ideal for industrial settings where workers are exposed to oil aerosols, such as in chemical manufacturing or petrochemical industries. The R Class respirators, like the R95, are somewhat resistant to oil and can be used in environments where oil-based particulates are present, but they are not as robust as the P Class in terms of oil resistance. They are suitable for short-term use in environments with oil aerosols. Each class of respirator is designed to meet specific needs, and the choice of which to use depends on the nature of the exposure and the level of protection required. The effectiveness of these respirators is also influenced by factors such as fit and seal, which are crucial for ensuring that the respirator provides the intended level of protection. Manufacturers are continually working to improve the design and comfort of these products, as a good fit is essential for optimal performance. Regulatory standards, such as those set by the National Institute for Occupational Safety and Health (NIOSH) in the United States, play a significant role in defining the specifications and testing requirements for these respirators. Compliance with these standards is essential for ensuring that the products meet the necessary safety and performance criteria. The market for these respirators is driven by factors such as increasing awareness of occupational health and safety, regulatory requirements, and the need for effective protection against airborne hazards. The demand for these products is expected to continue growing as industries and individuals prioritize safety and health in their operations and daily lives.

Medical & healthcare, Industrial, Chemical & Petrochemical, Pharmaceutical, Military, Food & Beverage, Fire services, Mining, Oil & Gas, Others in the Global Disposable Filtering Facepiece Respirators (FFR) Market:

The usage of Global Disposable Filtering Facepiece Respirators (FFR) spans across various sectors, each with unique requirements and challenges. In the medical and healthcare sector, these respirators are indispensable for protecting healthcare workers from infectious agents, particularly during pandemics like COVID-19. They help prevent the transmission of airborne diseases, ensuring the safety of both healthcare providers and patients. In industrial settings, FFRs are used to protect workers from dust, fumes, and other hazardous particles that are prevalent in manufacturing and construction environments. The chemical and petrochemical industries also rely heavily on these respirators to safeguard workers from exposure to harmful chemicals and oil-based aerosols. In the pharmaceutical industry, FFRs are crucial for maintaining a sterile environment and protecting workers from exposure to active pharmaceutical ingredients. The military uses these respirators to protect personnel from chemical and biological threats, ensuring their safety in various operational scenarios. In the food and beverage industry, FFRs help maintain hygiene standards by preventing contamination during food processing and packaging. Fire services use these respirators to protect firefighters from smoke and toxic gases during firefighting operations. In the mining industry, FFRs are essential for protecting miners from dust and other airborne contaminants that are common in mining environments. The oil and gas industry also relies on these respirators to protect workers from exposure to hazardous gases and vapors. Other sectors, such as agriculture and waste management, also use FFRs to protect workers from various airborne hazards. The versatility and effectiveness of disposable FFRs make them a critical component of safety protocols across these diverse industries. Their ability to provide reliable protection against a wide range of airborne hazards ensures that workers can perform their duties safely and efficiently.

Global Disposable Filtering Facepiece Respirators (FFR) Market Outlook:

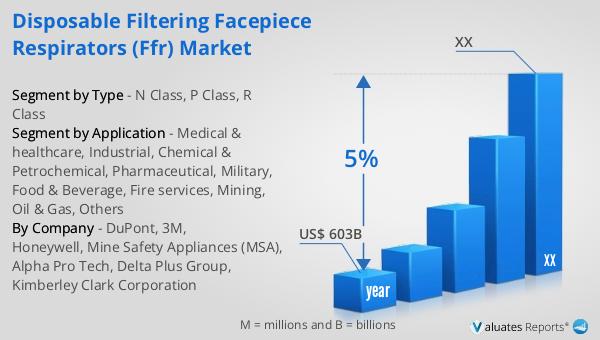

Our research indicates that the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including technological advancements, an aging global population, and increasing healthcare expenditure. The demand for innovative medical devices that improve patient outcomes and streamline healthcare delivery is on the rise. Additionally, the COVID-19 pandemic has highlighted the importance of medical devices in managing public health crises, further fueling market growth. The market is also benefiting from increased investment in healthcare infrastructure and the adoption of digital health technologies. As healthcare systems worldwide strive to improve efficiency and accessibility, the demand for advanced medical devices is expected to continue growing. This growth presents significant opportunities for manufacturers and investors in the medical device industry. The market's expansion is also supported by favorable regulatory environments and government initiatives aimed at improving healthcare access and quality. As a result, the global medical device market is poised for sustained growth, driven by innovation and the increasing need for effective healthcare solutions.

| Report Metric | Details |

| Report Name | Disposable Filtering Facepiece Respirators (FFR) Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | DuPont, 3M, Honeywell, Mine Safety Appliances (MSA), Alpha Pro Tech, Delta Plus Group, Kimberley Clark Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |