What is Global Cutting Deburring Machine Market?

The Global Cutting Deburring Machine Market is a specialized segment within the manufacturing industry that focuses on machines designed to remove burrs, which are unwanted rough edges or protrusions left on metal parts after a cutting process. These machines are essential in ensuring that metal components are smooth, safe, and ready for further processing or assembly. The market encompasses a variety of machines, each tailored to specific industrial needs, ranging from small-scale manual machines to large, automated systems. The demand for cutting deburring machines is driven by the need for precision and efficiency in industries such as automotive, aerospace, and electronics, where the quality of metal parts is crucial. As industries continue to advance and require more sophisticated components, the market for cutting deburring machines is expected to grow, offering innovative solutions to meet the evolving needs of manufacturers worldwide. The market's growth is also fueled by technological advancements that enhance the capabilities of these machines, making them more efficient and versatile. Overall, the Global Cutting Deburring Machine Market plays a vital role in the manufacturing sector by ensuring the production of high-quality metal parts that meet stringent industry standards.

Manual Deburring Machine, Automatic Deburring Machine in the Global Cutting Deburring Machine Market:

Manual Deburring Machines and Automatic Deburring Machines are two primary categories within the Global Cutting Deburring Machine Market, each serving distinct purposes and catering to different industrial needs. Manual Deburring Machines are typically used in smaller operations or for tasks that require a high degree of precision and control. These machines rely on human operators to guide the deburring process, making them ideal for intricate or delicate work where a personal touch is necessary. They are often more affordable than their automatic counterparts and are favored in industries where customization and flexibility are paramount. Manual machines are also easier to maintain and require less initial investment, making them accessible to smaller businesses or workshops. On the other hand, Automatic Deburring Machines are designed for high-volume production environments where speed and consistency are critical. These machines use advanced technology, such as robotics and computer numerical control (CNC), to automate the deburring process, significantly reducing the need for human intervention. Automatic machines are capable of handling large batches of parts with uniform precision, making them indispensable in industries like automotive and aerospace, where large-scale production and stringent quality standards are the norm. The integration of automation in deburring processes not only enhances efficiency but also minimizes the risk of human error, leading to improved product quality and reduced waste. Furthermore, automatic machines can be programmed to handle a variety of tasks, offering versatility and adaptability to changing production needs. As technology continues to evolve, the capabilities of automatic deburring machines are expected to expand, incorporating features such as real-time monitoring and data analytics to further optimize the manufacturing process. Despite their higher cost, the long-term benefits of automatic deburring machines, such as increased productivity and reduced labor costs, make them a worthwhile investment for many large-scale manufacturers. In summary, while manual deburring machines offer precision and flexibility for smaller operations, automatic deburring machines provide the speed and consistency needed for large-scale production, each playing a crucial role in the Global Cutting Deburring Machine Market.

Industrial, Automobile Industry, Others in the Global Cutting Deburring Machine Market:

The Global Cutting Deburring Machine Market finds extensive usage across various sectors, including industrial manufacturing, the automobile industry, and other specialized fields. In industrial manufacturing, deburring machines are essential for ensuring that metal parts are free from sharp edges and imperfections that could affect the performance or safety of the final product. Industries such as aerospace, electronics, and heavy machinery rely on deburring machines to produce components that meet precise specifications and quality standards. The ability to produce smooth, burr-free parts is crucial in these sectors, where even minor defects can lead to significant issues in performance or safety. In the automobile industry, deburring machines play a vital role in the production of engine components, transmission parts, and other critical automotive elements. The automotive sector demands high precision and consistency, as the performance and safety of vehicles depend on the quality of their components. Deburring machines help manufacturers achieve the necessary level of precision by removing any imperfections that could compromise the integrity of the parts. Additionally, the use of deburring machines in the automotive industry contributes to the overall efficiency of the production process, reducing the time and labor required to produce high-quality components. Beyond industrial and automotive applications, deburring machines are also used in other specialized fields, such as medical device manufacturing and consumer electronics. In the medical field, the production of surgical instruments and implants requires the highest level of precision and cleanliness, making deburring machines indispensable for ensuring that these products meet stringent regulatory standards. Similarly, in the consumer electronics industry, deburring machines are used to produce components that are not only functional but also aesthetically pleasing, as the appearance of electronic devices is a significant factor in consumer purchasing decisions. Overall, the Global Cutting Deburring Machine Market serves a wide range of industries by providing the tools necessary to produce high-quality, precision-engineered components that meet the demands of modern manufacturing.

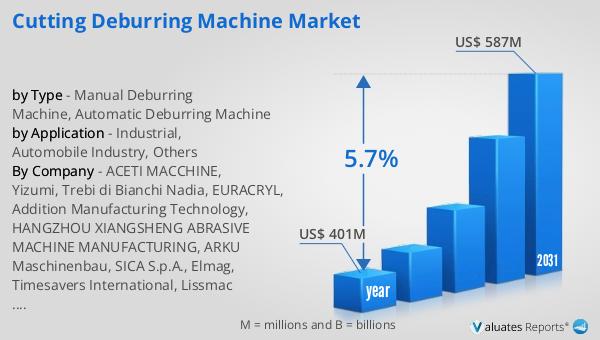

Global Cutting Deburring Machine Market Outlook:

The outlook for the Global Cutting Deburring Machine Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $401 million, reflecting the significant demand for these machines across various industries. By 2031, the market is projected to expand to a revised size of $587 million, driven by a compound annual growth rate (CAGR) of 5.7% during the forecast period. This growth is indicative of the increasing reliance on cutting deburring machines to enhance manufacturing processes and improve product quality. As industries continue to evolve and demand more sophisticated and precise components, the need for efficient deburring solutions is expected to rise. The market's expansion is also supported by technological advancements that enhance the capabilities of deburring machines, making them more efficient and versatile. These advancements allow manufacturers to meet the growing demands for high-quality metal parts while optimizing production processes. The projected growth of the Global Cutting Deburring Machine Market underscores the importance of these machines in modern manufacturing, as they play a crucial role in ensuring the production of components that meet stringent industry standards. As a result, the market is poised to continue its upward trajectory, offering innovative solutions to meet the evolving needs of manufacturers worldwide.

| Report Metric | Details |

| Report Name | Cutting Deburring Machine Market |

| Accounted market size in year | US$ 401 million |

| Forecasted market size in 2031 | US$ 587 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ACETI MACCHINE, Yizumi, Trebi di Bianchi Nadia, EURACRYL, Addition Manufacturing Technology, HANGZHOU XIANGSHENG ABRASIVE MACHINE MANUFACTURING, ARKU Maschinenbau, SICA S.p.A., Elmag, Timesavers International, Lissmac Maschinenbau, NS Máquinas Industriais, RSA Cutting Systems, BÖHLI, Apex Machine Group, Q-fin Quality Finishing, KOHLER Maschinenbau, LOEWER Maschinenbau |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |