What is Global Croissant Production Line Market?

The Global Croissant Production Line Market refers to the industry focused on the manufacturing and distribution of machinery and equipment used to produce croissants on a large scale. Croissants, known for their flaky texture and buttery taste, are a staple in bakeries worldwide, and their production requires specialized equipment to ensure consistency and efficiency. The market encompasses various types of production lines, including fully automatic and semi-automatic systems, designed to cater to different production capacities and operational needs. These production lines are essential for food processing plants and bakeries aiming to meet the growing demand for croissants, driven by their popularity as a breakfast item and snack. The market's growth is influenced by factors such as technological advancements in food processing equipment, increasing consumer preference for convenience foods, and the expansion of bakery chains globally. As the demand for croissants continues to rise, the Global Croissant Production Line Market plays a crucial role in enabling manufacturers to scale up production while maintaining product quality and reducing operational costs.

Fully Automatic Production Line, Semi-Automatic Production Line in the Global Croissant Production Line Market:

In the Global Croissant Production Line Market, production lines are categorized into fully automatic and semi-automatic systems, each offering distinct advantages and catering to different operational needs. Fully automatic production lines are designed to handle the entire croissant-making process with minimal human intervention. These systems are equipped with advanced technology that automates tasks such as dough mixing, rolling, cutting, shaping, and baking. The primary advantage of fully automatic lines is their ability to produce large quantities of croissants consistently and efficiently, making them ideal for large-scale food processing plants and industrial bakeries. These lines are often integrated with computerized control systems that allow operators to monitor and adjust production parameters, ensuring optimal product quality and minimizing waste. Additionally, fully automatic lines can be customized to produce various croissant sizes and shapes, catering to diverse consumer preferences. On the other hand, semi-automatic production lines combine automated processes with manual operations, offering a balance between efficiency and flexibility. These systems typically automate labor-intensive tasks such as dough sheeting and cutting, while allowing operators to manually handle tasks like shaping and filling. Semi-automatic lines are suitable for medium-sized bakeries and food processing plants that require a certain level of customization in their production process. The flexibility of semi-automatic lines allows manufacturers to experiment with different croissant recipes and fillings, catering to niche markets and consumer trends. Moreover, these lines are often more cost-effective than fully automatic systems, making them an attractive option for businesses with budget constraints or those looking to gradually scale up their production capacity. Both fully automatic and semi-automatic production lines contribute significantly to the efficiency and productivity of the Global Croissant Production Line Market. The choice between the two depends on factors such as production volume, budget, and the level of customization required. Fully automatic lines are ideal for high-volume production and standardized products, while semi-automatic lines offer the flexibility needed for artisanal and specialty croissants. As technology continues to advance, both types of production lines are expected to incorporate more sophisticated features, such as improved energy efficiency, enhanced safety measures, and advanced data analytics for real-time monitoring and optimization. These innovations will further enhance the capabilities of croissant production lines, enabling manufacturers to meet the evolving demands of the global market.

Food Processing Plants, Bakery, Other in the Global Croissant Production Line Market:

The Global Croissant Production Line Market finds its application in various sectors, including food processing plants, bakeries, and other related industries. In food processing plants, croissant production lines are essential for large-scale manufacturing operations. These plants require high-capacity equipment to produce croissants in bulk, catering to the demands of supermarkets, hotels, and restaurants. The use of fully automatic production lines in food processing plants ensures consistent product quality and reduces labor costs, as the entire production process is automated. This efficiency is crucial for meeting the high demand for croissants in the global market, especially in regions where they are a popular breakfast item or snack. In bakeries, croissant production lines play a vital role in streamlining operations and enhancing productivity. Both fully automatic and semi-automatic lines are used, depending on the size and scale of the bakery. Large commercial bakeries often opt for fully automatic lines to maximize output and maintain consistency in their products. These lines allow bakeries to produce a wide variety of croissants, from classic butter croissants to filled and flavored options, catering to diverse consumer preferences. Smaller artisanal bakeries, on the other hand, may prefer semi-automatic lines that offer more flexibility and allow for creative experimentation with different recipes and fillings. The ability to produce high-quality croissants efficiently is a key factor in the success of bakeries in the competitive food industry. Beyond food processing plants and bakeries, the Global Croissant Production Line Market also serves other sectors, such as catering companies and hospitality businesses. These industries require reliable and efficient production lines to meet the demands of their clients and customers. For instance, catering companies that provide breakfast and brunch services often rely on croissant production lines to ensure a steady supply of fresh and delicious pastries. Similarly, hotels and resorts with in-house bakeries use these production lines to offer a variety of croissants to their guests, enhancing their dining experience. The versatility and efficiency of croissant production lines make them an invaluable asset in these industries, enabling businesses to deliver high-quality products consistently. Overall, the Global Croissant Production Line Market plays a crucial role in supporting the food industry by providing the necessary equipment and technology for efficient croissant production. Whether in large-scale food processing plants, commercial bakeries, or other related sectors, these production lines enable businesses to meet the growing demand for croissants while maintaining product quality and operational efficiency. As consumer preferences continue to evolve, the market is expected to adapt and innovate, offering new solutions and technologies to enhance the capabilities of croissant production lines.

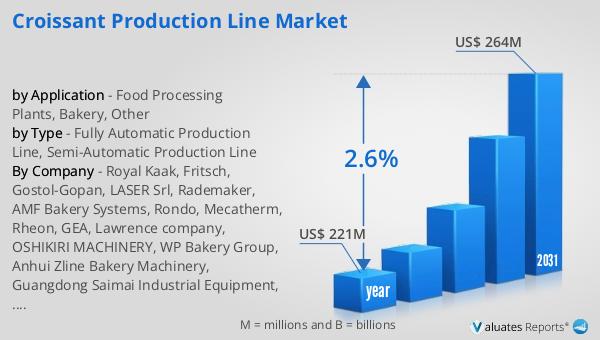

Global Croissant Production Line Market Outlook:

In 2024, the global market for Croissant Production Line was valued at approximately $221 million. Looking ahead, this market is anticipated to expand, reaching an estimated value of $264 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 2.6% over the forecast period. The steady increase in market size underscores the rising demand for croissant production equipment, driven by the growing popularity of croissants as a convenient and delicious food option. As more consumers seek out high-quality baked goods, manufacturers are investing in advanced production lines to enhance efficiency and meet market demands. The projected growth also highlights the importance of technological advancements in the industry, as companies strive to improve production processes and reduce operational costs. With the market poised for expansion, businesses involved in the Global Croissant Production Line Market are well-positioned to capitalize on emerging opportunities and drive innovation in the sector. This positive outlook reflects the ongoing evolution of consumer preferences and the increasing emphasis on convenience and quality in the food industry.

| Report Metric | Details |

| Report Name | Croissant Production Line Market |

| Accounted market size in year | US$ 221 million |

| Forecasted market size in 2031 | US$ 264 million |

| CAGR | 2.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Royal Kaak, Fritsch, Gostol-Gopan, LASER Srl, Rademaker, AMF Bakery Systems, Rondo, Mecatherm, Rheon, GEA, Lawrence company, OSHIKIRI MACHINERY, WP Bakery Group, Anhui Zline Bakery Machinery, Guangdong Saimai Industrial Equipment, Anhui Hengyuan Food Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |