What is Global Copper Sintering Paste Market?

The Global Copper Sintering Paste Market is a specialized segment within the broader materials and electronics industry, focusing on the production and application of copper-based sintering pastes. These pastes are primarily used in the electronics sector for creating reliable and efficient connections in various electronic components. Copper sintering paste is a mixture of copper particles and a binding agent, which, when heated, allows the copper particles to bond together, forming a solid conductive path. This process is crucial in the manufacturing of electronic devices, as it ensures high thermal and electrical conductivity, which is essential for the performance and longevity of electronic components. The market for copper sintering paste is driven by the increasing demand for miniaturized and high-performance electronic devices, which require advanced materials to meet stringent performance standards. Additionally, the shift towards more environmentally friendly and cost-effective materials in electronics manufacturing has further propelled the demand for copper sintering pastes, as they offer a viable alternative to traditional soldering methods. The market is characterized by continuous innovation and development, with manufacturers focusing on enhancing the properties of copper sintering pastes to cater to the evolving needs of the electronics industry.

Pressure Sintered Paste, Non-pressure Sintering Paste in the Global Copper Sintering Paste Market:

Pressure sintered paste and non-pressure sintering paste are two distinct types of materials used within the Global Copper Sintering Paste Market, each with unique properties and applications. Pressure sintered paste involves the application of external pressure during the sintering process, which helps in achieving a denser and more uniform microstructure. This method is particularly beneficial in applications where high mechanical strength and thermal conductivity are required. The pressure applied during the sintering process aids in reducing porosity, thereby enhancing the overall performance of the sintered product. This type of paste is often used in high-performance electronic applications where reliability and durability are paramount. On the other hand, non-pressure sintering paste does not require the application of external pressure during the sintering process. Instead, it relies on the inherent properties of the paste and the sintering temperature to achieve the desired bonding and conductivity. Non-pressure sintering paste is typically used in applications where the manufacturing process needs to be simplified, or where the application of pressure is not feasible. This type of paste is advantageous in terms of cost and ease of processing, making it suitable for a wide range of electronic applications. Both pressure and non-pressure sintering pastes play a crucial role in the electronics industry, providing manufacturers with the flexibility to choose the most appropriate material based on the specific requirements of their applications. The choice between pressure and non-pressure sintering paste depends on various factors, including the desired properties of the final product, the complexity of the manufacturing process, and cost considerations. As the demand for advanced electronic devices continues to grow, the development and optimization of both pressure and non-pressure sintering pastes remain a key focus for manufacturers in the Global Copper Sintering Paste Market. Innovations in material composition, processing techniques, and application methods are continually being explored to enhance the performance and applicability of these pastes in various electronic applications. The ongoing research and development efforts in this field are expected to lead to the introduction of new and improved sintering pastes that offer superior performance, reliability, and cost-effectiveness. As a result, both pressure and non-pressure sintering pastes are poised to play an increasingly important role in the advancement of electronic technologies, catering to the ever-evolving needs of the industry.

Power Module Chips, Semiconductor Testing, RF Power Device, Others in the Global Copper Sintering Paste Market:

The Global Copper Sintering Paste Market finds its applications in several key areas, including power module chips, semiconductor testing, RF power devices, and others. In the realm of power module chips, copper sintering paste is used to create reliable and efficient connections between the chip and the substrate. The high thermal and electrical conductivity of copper makes it an ideal material for power modules, which require efficient heat dissipation to maintain performance and prevent overheating. The use of copper sintering paste in power modules helps in enhancing the overall efficiency and reliability of these components, which are critical in various applications, including renewable energy systems, electric vehicles, and industrial automation. In semiconductor testing, copper sintering paste is used to establish temporary connections between the semiconductor device and the testing equipment. The paste provides a stable and conductive path, ensuring accurate testing results. The use of copper sintering paste in semiconductor testing is particularly beneficial in high-frequency applications, where signal integrity is crucial. The paste's excellent conductivity and thermal properties help in minimizing signal loss and ensuring reliable test outcomes. RF power devices, which are used in wireless communication systems, also benefit from the use of copper sintering paste. The paste is used to create connections between the RF device and the circuit board, ensuring efficient signal transmission and heat dissipation. The high conductivity of copper helps in minimizing signal loss, while its thermal properties aid in managing the heat generated during operation. This is particularly important in RF power devices, which operate at high frequencies and require efficient thermal management to maintain performance and reliability. Beyond these specific applications, copper sintering paste is also used in a variety of other electronic components and systems. Its versatility and excellent properties make it suitable for use in a wide range of applications, from consumer electronics to industrial equipment. The ongoing advancements in electronic technologies and the increasing demand for high-performance devices continue to drive the adoption of copper sintering paste in various sectors. As manufacturers seek to enhance the performance and reliability of their products, the use of advanced materials like copper sintering paste becomes increasingly important. The Global Copper Sintering Paste Market is poised to play a crucial role in the development of next-generation electronic devices, providing manufacturers with the materials they need to meet the evolving demands of the industry.

Global Copper Sintering Paste Market Outlook:

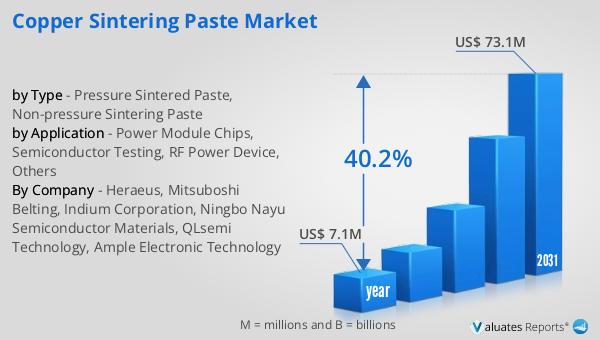

The global market for copper sintering paste was valued at $7.1 million in 2024, and it is anticipated to expand significantly, reaching an estimated size of $73.1 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 40.2% over the forecast period. Such a robust growth rate underscores the increasing demand for copper sintering paste across various industries, driven by the need for advanced materials that offer superior thermal and electrical conductivity. The electronics industry, in particular, is a major driver of this market, as manufacturers seek to enhance the performance and reliability of their products through the use of innovative materials like copper sintering paste. The projected growth of the market also reflects the ongoing advancements in electronic technologies and the increasing adoption of copper sintering paste in a wide range of applications, from power modules to RF power devices. As the market continues to evolve, manufacturers are expected to focus on developing new and improved sintering pastes that cater to the specific needs of different applications, further driving the growth of the Global Copper Sintering Paste Market. The significant expansion of the market highlights the critical role that copper sintering paste plays in the advancement of electronic technologies, providing manufacturers with the materials they need to meet the ever-evolving demands of the industry.

| Report Metric | Details |

| Report Name | Copper Sintering Paste Market |

| Accounted market size in year | US$ 7.1 million |

| Forecasted market size in 2031 | US$ 73.1 million |

| CAGR | 40.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Heraeus, Mitsuboshi Belting, Indium Corporation, Ningbo Nayu Semiconductor Materials, QLsemi Technology, Ample Electronic Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |