What is Global Copper Polishing Slurry Market?

The Global Copper Polishing Slurry Market is a specialized segment within the broader semiconductor industry, focusing on the materials used in the chemical mechanical planarization (CMP) process. CMP is a critical step in semiconductor manufacturing, where a slurry is used to smooth and flatten the surface of semiconductor wafers, particularly those made of copper. This process is essential for creating the intricate patterns required for modern electronic devices. The slurry typically consists of abrasive particles suspended in a chemical solution, which helps to remove excess material and achieve the desired surface finish. The demand for copper polishing slurry is driven by the increasing complexity of semiconductor devices and the need for higher performance and miniaturization. As technology advances, the requirements for precision and efficiency in the CMP process become more stringent, leading to innovations in slurry formulations. The market is characterized by a focus on developing slurries that offer improved removal rates, selectivity, and defectivity, while also being environmentally friendly. This market is poised for growth as the semiconductor industry continues to expand, driven by the proliferation of electronic devices and the ongoing development of new technologies.

Colloidal Silica Based Slurry, Alumina Based Slurry in the Global Copper Polishing Slurry Market:

Colloidal silica-based slurry and alumina-based slurry are two prominent types of slurries used in the Global Copper Polishing Slurry Market, each with distinct characteristics and applications. Colloidal silica-based slurry is known for its fine particle size and uniform distribution, which makes it ideal for achieving a high-quality surface finish with minimal defects. The silica particles are suspended in a chemical solution that facilitates the removal of excess copper material during the CMP process. This type of slurry is particularly effective in applications where a smooth and defect-free surface is critical, such as in the production of advanced semiconductor devices. The chemical composition of colloidal silica-based slurry can be tailored to enhance its performance, allowing for precise control over the polishing process. On the other hand, alumina-based slurry is characterized by its harder abrasive particles, which provide a higher removal rate compared to colloidal silica-based slurry. This makes it suitable for applications where rapid material removal is necessary, such as in the initial stages of the CMP process. Alumina-based slurry is often used in conjunction with other types of slurries to achieve the desired balance between removal rate and surface finish. The choice between colloidal silica-based and alumina-based slurry depends on the specific requirements of the application, including the type of semiconductor device being manufactured and the desired surface characteristics. Both types of slurries play a crucial role in the CMP process, contributing to the overall efficiency and effectiveness of semiconductor manufacturing. As the demand for more advanced and miniaturized electronic devices continues to grow, the development of new and improved slurry formulations will be essential to meet the evolving needs of the industry.

Logic Chips, Memory Chips, Advanced Packaging in the Global Copper Polishing Slurry Market:

The Global Copper Polishing Slurry Market plays a vital role in the production of various semiconductor components, including logic chips, memory chips, and advanced packaging. Logic chips, which are used to perform the processing functions in electronic devices, require a high degree of precision and accuracy during manufacturing. The CMP process, facilitated by copper polishing slurry, is essential for creating the intricate patterns and structures needed for these chips to function effectively. The slurry helps to achieve the necessary surface planarity and smoothness, ensuring that the logic chips can operate at high speeds and with minimal power consumption. Memory chips, which are used to store data in electronic devices, also benefit from the use of copper polishing slurry. The CMP process helps to create the fine structures required for high-density memory storage, allowing for greater data capacity and faster access times. The use of copper polishing slurry in the production of memory chips is critical for meeting the increasing demand for more powerful and efficient storage solutions. Advanced packaging, which involves the integration of multiple semiconductor components into a single package, also relies on the CMP process and copper polishing slurry. This process is essential for ensuring the proper alignment and connection of the various components, which is crucial for the performance and reliability of the final product. The use of copper polishing slurry in advanced packaging helps to achieve the necessary surface finish and planarity, enabling the production of more compact and efficient electronic devices. As the semiconductor industry continues to evolve, the role of copper polishing slurry in the production of logic chips, memory chips, and advanced packaging will remain critical, driving further innovation and development in this market.

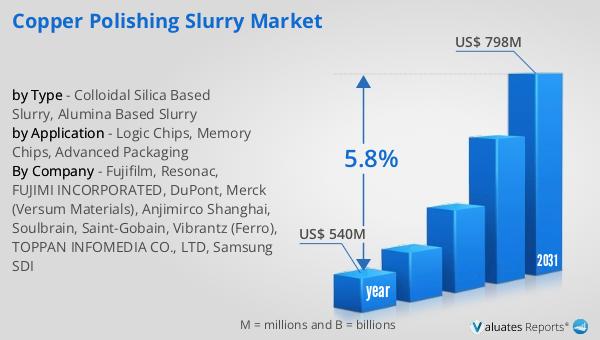

Global Copper Polishing Slurry Market Outlook:

In 2024, the global market for Copper Polishing Slurry was valued at approximately $540 million, and it is anticipated to grow to a revised size of $798 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% over the forecast period. This growth is indicative of the increasing demand for advanced semiconductor devices and the critical role that copper polishing slurry plays in their production. The broader semiconductor market was estimated at $526.8 billion in 2023 and is projected to reach $780.7 billion by 2030. This expansion underscores the rapid advancements in technology and the growing need for more sophisticated electronic components. Additionally, the global semiconductor manufacturing wafer fabrication market is expected to grow from $251.7 billion in 2023 to $506.5 billion by 2030, with a remarkable CAGR of 40.49% during the forecast period. This significant growth highlights the importance of copper polishing slurry in the semiconductor manufacturing process, as it is essential for achieving the precision and quality required for modern electronic devices. The continued development and innovation in slurry formulations will be crucial for supporting the evolving needs of the semiconductor industry and maintaining the momentum of market growth.

| Report Metric | Details |

| Report Name | Copper Polishing Slurry Market |

| Accounted market size in year | US$ 540 million |

| Forecasted market size in 2031 | US$ 798 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fujifilm, Resonac, FUJIMI INCORPORATED, DuPont, Merck (Versum Materials), Anjimirco Shanghai, Soulbrain, Saint-Gobain, Vibrantz (Ferro), TOPPAN INFOMEDIA CO., LTD, Samsung SDI |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |