What is Global CNC Machine Tool Blade Market?

The Global CNC Machine Tool Blade Market is a dynamic and rapidly evolving sector that plays a crucial role in modern manufacturing industries. CNC, which stands for Computer Numerical Control, refers to the automated control of machining tools by means of a computer. These machines are used to cut, shape, and finish materials such as metal, plastic, and wood with high precision and efficiency. The market for CNC machine tool blades is integral to this process, as these blades are the components that perform the actual cutting and shaping tasks. The demand for CNC machine tool blades is driven by the need for high-quality, precise, and efficient manufacturing processes across various industries, including automotive, aerospace, and electronics. As industries continue to advance technologically, the need for sophisticated and reliable CNC machine tools and their components, like blades, is expected to grow. This market is characterized by continuous innovation, with manufacturers striving to develop blades that offer greater durability, precision, and efficiency. The global reach of this market is significant, with key players operating in regions such as North America, Europe, and Asia-Pacific, each contributing to the overall growth and development of the industry.

Turning Tool Blade, Drilling Tool Blade, Milling Tool Blade in the Global CNC Machine Tool Blade Market:

Turning tool blades, drilling tool blades, and milling tool blades are essential components of the Global CNC Machine Tool Blade Market, each serving distinct functions in the machining process. Turning tool blades are primarily used in lathes to remove material from the outer diameter of a rotating workpiece. This process is crucial for creating cylindrical parts and is widely used in industries such as automotive and aerospace, where precision and accuracy are paramount. Turning tool blades are designed to withstand high temperatures and pressures, ensuring they can perform consistently over extended periods. Drilling tool blades, on the other hand, are used to create holes in a workpiece. These blades are essential in manufacturing processes that require precise hole dimensions and smooth finishes. Drilling is a common operation in various industries, including construction, automotive, and electronics, where components often need to be assembled with precision. The design of drilling tool blades focuses on sharpness and durability to ensure efficient material removal and minimal wear. Milling tool blades are used in milling machines to remove material from a workpiece by advancing a cutter into it. This process is versatile and can produce a wide range of shapes, slots, and holes. Milling is a critical operation in industries such as aerospace, where complex geometries and tight tolerances are required. Milling tool blades are designed to handle various materials, from soft metals to hardened steel, and are engineered to provide high precision and surface finish. The Global CNC Machine Tool Blade Market is driven by the need for these specialized blades, each tailored to specific machining operations. Manufacturers in this market focus on developing blades that offer enhanced performance, longer lifespan, and greater efficiency. The continuous advancement in materials and coating technologies plays a significant role in improving the capabilities of these blades, allowing them to meet the ever-increasing demands of modern manufacturing. As industries continue to evolve, the importance of turning, drilling, and milling tool blades in the CNC machine tool market remains paramount, driving innovation and growth in this sector.

Automobile, Aerospace & Defense, Machinery Manufacturing, Others in the Global CNC Machine Tool Blade Market:

The Global CNC Machine Tool Blade Market finds extensive usage across various industries, including automobile, aerospace and defense, machinery manufacturing, and others, each benefiting from the precision and efficiency these tools offer. In the automobile industry, CNC machine tool blades are crucial for manufacturing components with high precision and consistency. The production of engine parts, transmission components, and other critical automotive parts relies heavily on CNC machining to ensure that each piece meets stringent quality standards. The ability to produce complex geometries with tight tolerances makes CNC machine tools indispensable in this sector, where performance and reliability are non-negotiable. In the aerospace and defense industry, the demand for CNC machine tool blades is driven by the need for precision and durability. Aircraft components, such as turbine blades, structural parts, and landing gear, require machining processes that can deliver high accuracy and superior surface finishes. CNC machine tools enable manufacturers to produce these components with the necessary precision, ensuring the safety and performance of aircraft. The defense sector also benefits from CNC machining, as it allows for the production of complex parts used in military equipment and vehicles. In machinery manufacturing, CNC machine tool blades are used to produce a wide range of equipment and machinery components. The ability to machine parts with high precision and repeatability is essential in this industry, where the quality and performance of machinery depend on the accuracy of its components. CNC machining allows manufacturers to produce parts that meet exact specifications, ensuring the reliability and efficiency of the machinery. Other industries, such as electronics, medical devices, and construction, also benefit from the capabilities of CNC machine tools. In electronics, CNC machining is used to produce components with intricate designs and precise dimensions, essential for the functionality of electronic devices. In the medical field, CNC machine tools are used to manufacture surgical instruments and implants with high precision, ensuring patient safety and treatment efficacy. The construction industry uses CNC machining for producing components that require precise dimensions and high-quality finishes. Overall, the Global CNC Machine Tool Blade Market plays a vital role in enhancing the capabilities of various industries, enabling them to produce high-quality products with efficiency and precision.

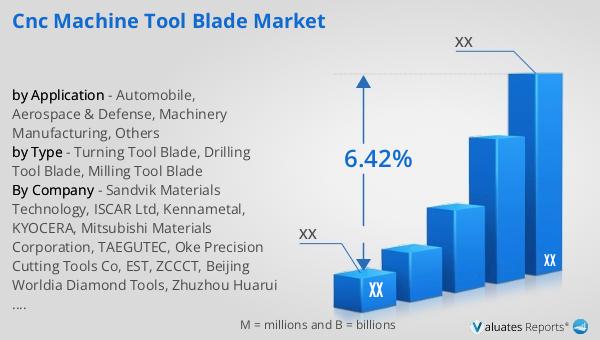

Global CNC Machine Tool Blade Market Outlook:

The Global CNC Machine Tool Market was valued at USD 82.03 billion in 2021 and is projected to reach USD 126.8 billion by 2028, growing at a compound annual growth rate (CAGR) of 6.42% over the forecast period. This growth reflects the increasing demand for CNC machine tools across various industries, driven by the need for precision, efficiency, and automation in manufacturing processes. The market's expansion is fueled by technological advancements in CNC machinery, which enhance the capabilities of these tools and enable manufacturers to produce complex parts with high accuracy and consistency. As industries continue to evolve and adopt more sophisticated manufacturing techniques, the demand for CNC machine tools is expected to rise, contributing to the market's growth. The increasing focus on automation and digitalization in manufacturing processes is also a significant factor driving the market's expansion. CNC machine tools offer the advantage of reducing manual intervention, improving production efficiency, and minimizing errors, making them an attractive option for manufacturers seeking to enhance their operations. Additionally, the growing emphasis on sustainability and energy efficiency in manufacturing is likely to further boost the demand for CNC machine tools, as these machines are designed to optimize resource utilization and reduce waste. The market's growth is also supported by the rising demand for high-quality products in industries such as automotive, aerospace, and electronics, where precision and reliability are critical. As these industries continue to advance and innovate, the need for CNC machine tools that can meet their stringent requirements is expected to increase, driving the market's growth over the forecast period.

| Report Metric | Details |

| Report Name | CNC Machine Tool Blade Market |

| CAGR | 6.42% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sandvik Materials Technology, ISCAR Ltd, Kennametal, KYOCERA, Mitsubishi Materials Corporation, TAEGUTEC, Oke Precision Cutting Tools Co, EST, ZCCCT, Beijing Worldia Diamond Tools, Zhuzhou Huarui Cemented Carbide Tools, Xiamen Golden Egret Special Alloy, Creatizit, MAPAL Dr. Kress KG, KORLOY, DongGuan Longside Tool Factory |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |