What is Global Carrier Tape Materials Market?

The Global Carrier Tape Materials Market is a specialized segment within the broader packaging industry, focusing on the production and distribution of materials used to create carrier tapes. Carrier tapes are essential components in the packaging of electronic components, particularly in the semiconductor industry. These tapes are designed to hold and protect small electronic parts during transportation and storage, ensuring they remain intact and undamaged. The materials used in carrier tapes must be durable, flexible, and capable of withstanding various environmental conditions. They are typically made from a range of polymers, each offering unique properties that cater to different packaging needs. The market for these materials is driven by the growing demand for electronic devices and advancements in semiconductor technology. As the electronics industry continues to expand, the need for reliable and efficient packaging solutions like carrier tapes becomes increasingly important. This market is characterized by continuous innovation, with manufacturers constantly seeking to improve the performance and sustainability of their products. The Global Carrier Tape Materials Market plays a crucial role in ensuring the safe and efficient delivery of electronic components worldwide, supporting the ever-evolving technology landscape.

PS, ABS, PET, Others in the Global Carrier Tape Materials Market:

In the Global Carrier Tape Materials Market, several types of polymers are predominantly used, each offering distinct advantages and characteristics that make them suitable for specific applications. Polystyrene (PS) is one of the most commonly used materials in carrier tapes due to its excellent clarity, rigidity, and ease of processing. PS is favored for its cost-effectiveness and ability to provide a stable and protective environment for electronic components. Its transparency allows for easy inspection of the components within the tape, which is crucial for quality control in manufacturing processes. However, PS is not the most environmentally friendly option, as it is derived from petroleum and is not biodegradable. Acrylonitrile Butadiene Styrene (ABS) is another popular material in the carrier tape market. ABS is known for its toughness, impact resistance, and ability to withstand high temperatures, making it ideal for applications that require durability and strength. It is often used in situations where the carrier tape needs to endure rough handling or extreme conditions. ABS is also relatively easy to mold and process, which makes it a versatile choice for manufacturers. However, like PS, ABS is not biodegradable and poses environmental challenges. Polyethylene Terephthalate (PET) is gaining popularity in the carrier tape market due to its excellent mechanical properties and environmental benefits. PET is a strong, lightweight, and recyclable material that offers good resistance to moisture and chemicals. Its recyclability makes it an attractive option for companies looking to reduce their environmental footprint. PET carrier tapes are often used in applications where sustainability is a priority, and they provide a balance between performance and eco-friendliness. Other materials used in the carrier tape market include polycarbonate, polyvinyl chloride (PVC), and polypropylene (PP). Each of these materials offers unique properties that cater to specific needs within the market. For example, polycarbonate is known for its high impact resistance and optical clarity, making it suitable for applications that require both strength and visibility. PVC is valued for its flexibility and chemical resistance, while PP is appreciated for its lightweight and cost-effectiveness. The choice of material for carrier tapes depends on various factors, including the type of electronic components being packaged, the environmental conditions they will be exposed to, and the sustainability goals of the manufacturer. As the demand for electronic devices continues to grow, the Global Carrier Tape Materials Market is expected to evolve, with manufacturers exploring new materials and technologies to meet the changing needs of the industry.

Semiconductor Packages, Electrical and Electronic Equipment in the Global Carrier Tape Materials Market:

The usage of Global Carrier Tape Materials Market is particularly significant in the areas of semiconductor packages and electrical and electronic equipment. In the semiconductor industry, carrier tapes are crucial for the packaging and transportation of delicate semiconductor packages. These packages contain integrated circuits and other sensitive components that require protection from physical damage, moisture, and electrostatic discharge. Carrier tapes made from materials like PS, ABS, and PET provide a secure and stable environment for these components, ensuring they reach their destination in optimal condition. The tapes are designed to fit precisely around the semiconductor packages, minimizing movement and reducing the risk of damage during transit. In addition to protection, carrier tapes also facilitate automated handling and assembly processes in semiconductor manufacturing. The tapes are compatible with pick-and-place machines, which are used to position components accurately on printed circuit boards. This automation is essential for maintaining efficiency and precision in high-volume production environments. In the realm of electrical and electronic equipment, carrier tapes play a vital role in the packaging of various components, such as resistors, capacitors, and connectors. These components are often small and fragile, requiring careful handling to prevent damage. Carrier tapes provide a convenient and efficient way to organize and transport these components, ensuring they remain intact and ready for assembly. The use of carrier tapes in this sector is driven by the need for reliable and cost-effective packaging solutions that can accommodate a wide range of component sizes and shapes. The materials used in carrier tapes must offer a balance of strength, flexibility, and environmental resistance to meet the diverse requirements of electrical and electronic equipment manufacturers. As the demand for electronic devices continues to rise, the importance of carrier tapes in ensuring the safe and efficient delivery of components cannot be overstated. The Global Carrier Tape Materials Market is poised to play a critical role in supporting the growth and innovation of the electronics industry, providing the necessary packaging solutions to meet the evolving needs of manufacturers worldwide.

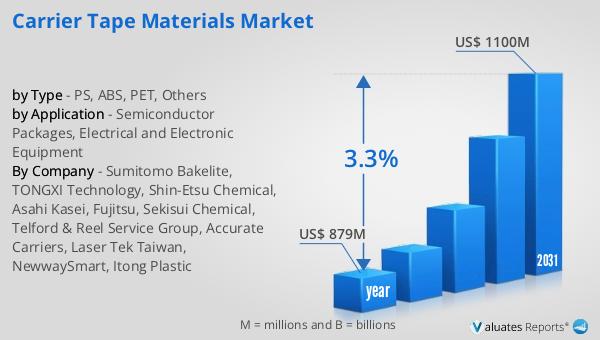

Global Carrier Tape Materials Market Outlook:

The outlook for the Global Carrier Tape Materials Market indicates a steady growth trajectory over the coming years. In 2024, the market was valued at approximately $879 million, reflecting its significant role in the packaging industry, particularly for electronic components. By 2031, the market is expected to expand to a revised size of $1.1 billion, driven by a compound annual growth rate (CAGR) of 3.3% during the forecast period. This growth is indicative of the increasing demand for reliable and efficient packaging solutions in the electronics sector. As technology continues to advance, the need for high-quality carrier tapes that can protect and transport delicate components becomes more pronounced. The market's expansion is also fueled by the ongoing development of new materials and technologies that enhance the performance and sustainability of carrier tapes. Manufacturers are investing in research and development to create innovative solutions that meet the evolving needs of the industry. The projected growth of the Global Carrier Tape Materials Market underscores its importance in supporting the electronics industry's continued expansion and innovation. As the market evolves, it will play a crucial role in ensuring the safe and efficient delivery of electronic components worldwide, contributing to the advancement of technology and the global economy.

| Report Metric | Details |

| Report Name | Carrier Tape Materials Market |

| Accounted market size in year | US$ 879 million |

| Forecasted market size in 2031 | US$ 1100 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sumitomo Bakelite, TONGXI Technology, Shin-Etsu Chemical, Asahi Kasei, Fujitsu, Sekisui Chemical, Telford & Reel Service Group, Accurate Carriers, Laser Tek Taiwan, NewwaySmart, Itong Plastic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |