What is Global Brazed Aluminium Heat Exchangers Market?

The Global Brazed Aluminium Heat Exchangers Market is a specialized segment within the broader heat exchanger industry, focusing on devices that use brazed aluminum to transfer heat between two or more fluids. These exchangers are known for their efficiency, compact size, and lightweight nature, making them ideal for various industrial applications. The brazing process involves joining aluminum components using a filler metal, which creates a strong bond capable of withstanding high pressures and temperatures. This market is driven by the increasing demand for energy-efficient solutions and the growing need for effective thermal management in industries such as petrochemicals, power generation, and air separation. The versatility of brazed aluminum heat exchangers allows them to be used in a wide range of applications, from cooling systems in power plants to cryogenic processes in air separation units. As industries continue to seek ways to reduce energy consumption and improve operational efficiency, the demand for these heat exchangers is expected to grow. The market is characterized by technological advancements, with manufacturers focusing on improving the performance and durability of their products to meet the evolving needs of their customers.

Flat Fins, Serrated Fins, Porous Fins, Others in the Global Brazed Aluminium Heat Exchangers Market:

In the Global Brazed Aluminium Heat Exchangers Market, different types of fins play a crucial role in enhancing the heat transfer capabilities of the exchangers. Flat fins, for instance, are simple in design and provide a basic surface area for heat exchange. They are typically used in applications where space is not a constraint and where moderate heat transfer efficiency is sufficient. The simplicity of flat fins makes them cost-effective and easy to manufacture, which can be advantageous in large-scale production settings. On the other hand, serrated fins are designed with a series of notches or serrations that increase the surface area available for heat transfer. This design enhances the turbulence of the fluid flow, thereby improving the overall heat transfer efficiency. Serrated fins are particularly useful in applications where maximizing heat exchange is critical, such as in high-performance cooling systems. Porous fins, meanwhile, offer a unique approach by incorporating a network of tiny pores that facilitate enhanced fluid mixing and heat transfer. The porous structure allows for a greater surface area in contact with the fluid, which can significantly boost the heat exchanger's performance. These fins are often used in specialized applications where traditional fin designs may not provide the desired level of efficiency. Other types of fins, such as louvered or wavy fins, also exist and are selected based on specific application requirements. Each type of fin offers distinct advantages and is chosen based on factors such as the desired heat transfer rate, pressure drop considerations, and the physical constraints of the installation space. The choice of fin type is a critical decision in the design of brazed aluminum heat exchangers, as it directly impacts the efficiency, cost, and performance of the system. Manufacturers in this market continually innovate to develop fin designs that offer improved heat transfer capabilities while minimizing pressure losses and material costs. This ongoing innovation is essential to meet the diverse needs of industries that rely on efficient thermal management solutions.

Air Separation, Petrochemical, Power Machinery, Defense, Others in the Global Brazed Aluminium Heat Exchangers Market:

Brazed Aluminium Heat Exchangers are widely used across various industries due to their efficiency and versatility. In the air separation industry, these heat exchangers play a vital role in the cryogenic process of separating air into its primary components, such as nitrogen, oxygen, and argon. The exchangers are used to cool the air to extremely low temperatures, facilitating the separation process. Their ability to withstand high pressures and temperatures makes them ideal for this application, ensuring reliable and efficient operation. In the petrochemical industry, brazed aluminum heat exchangers are used in processes such as gas processing, where they help in cooling and condensing hydrocarbon gases. Their compact size and high thermal efficiency make them suitable for use in environments where space is limited, and performance is critical. These exchangers contribute to the overall efficiency of petrochemical plants by reducing energy consumption and improving process reliability. In the power machinery sector, brazed aluminum heat exchangers are used in cooling systems for turbines and generators. They help maintain optimal operating temperatures, ensuring the machinery operates efficiently and reliably. The lightweight nature of these exchangers is particularly beneficial in power machinery applications, where reducing weight can lead to improved performance and reduced operational costs. In the defense industry, brazed aluminum heat exchangers are used in various applications, including cooling systems for military vehicles and equipment. Their durability and ability to operate under extreme conditions make them suitable for use in harsh environments. These exchangers help ensure the reliability and performance of defense systems, contributing to mission success. Other industries, such as automotive and aerospace, also benefit from the use of brazed aluminum heat exchangers. In the automotive industry, they are used in cooling systems for engines and transmissions, helping to improve fuel efficiency and reduce emissions. In aerospace, these exchangers are used in aircraft cooling systems, where their lightweight and compact design is particularly advantageous. Overall, the versatility and efficiency of brazed aluminum heat exchangers make them a valuable asset in a wide range of industrial applications.

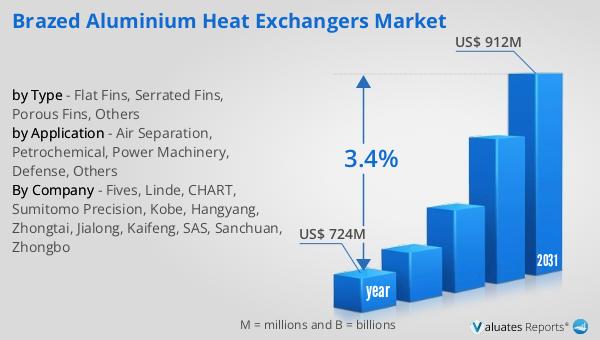

Global Brazed Aluminium Heat Exchangers Market Outlook:

The global market for Brazed Aluminium Heat Exchangers was valued at $724 million in 2024 and is anticipated to grow to a revised size of $912 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.4% over the forecast period. This growth is driven by the increasing demand for energy-efficient solutions and the need for effective thermal management across various industries. The Asia-Pacific region stands out as the largest consumer, accounting for more than 45% of the total market consumption. This significant share is attributed to the rapid industrialization and urbanization in countries like China and India, where the demand for efficient cooling and heating solutions is on the rise. The region's robust manufacturing sector and the growing focus on sustainable energy solutions further contribute to the high consumption of brazed aluminum heat exchangers. As industries in the Asia-Pacific region continue to expand and modernize, the demand for these heat exchangers is expected to remain strong. The market's growth is also supported by technological advancements, with manufacturers focusing on developing innovative products that offer improved performance and durability. This ongoing innovation is essential to meet the evolving needs of industries that rely on efficient thermal management solutions. Overall, the global market for brazed aluminum heat exchangers is poised for steady growth, driven by the increasing demand for energy-efficient solutions and the expanding industrial base in the Asia-Pacific region.

| Report Metric | Details |

| Report Name | Brazed Aluminium Heat Exchangers Market |

| Accounted market size in year | US$ 724 million |

| Forecasted market size in 2031 | US$ 912 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fives, Linde, CHART, Sumitomo Precision, Kobe, Hangyang, Zhongtai, Jialong, Kaifeng, SAS, Sanchuan, Zhongbo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |