What is Global Belting Machine Market?

The Global Belting Machine Market is a dynamic and evolving sector that plays a crucial role in various industries by providing essential machinery for material handling and processing. Belting machines are used to automate the process of moving goods and materials efficiently, which is vital for industries such as manufacturing, logistics, and pharmaceuticals. These machines are designed to handle different types of materials, including heavy loads and delicate items, ensuring that they are transported safely and efficiently. The market for belting machines is driven by the increasing demand for automation in industrial processes, which helps in reducing labor costs and improving productivity. Additionally, advancements in technology have led to the development of more sophisticated belting machines that offer enhanced performance and reliability. As industries continue to expand and modernize, the demand for belting machines is expected to grow, making it a significant area of interest for manufacturers and investors alike. The global belting machine market is characterized by a diverse range of products and solutions, catering to the specific needs of different industries, and is poised for continued growth in the coming years.

Semi-Automatic, Full-Automatic in the Global Belting Machine Market:

In the Global Belting Machine Market, semi-automatic and full-automatic machines represent two key categories that cater to different operational needs and preferences. Semi-automatic belting machines require some level of human intervention to operate. They are typically used in settings where flexibility and manual oversight are necessary. These machines are ideal for small to medium-sized operations where the volume of goods being processed does not justify the investment in fully automated systems. Semi-automatic machines offer the advantage of being more affordable and easier to maintain, making them a popular choice for businesses that are just starting to automate their processes. They allow operators to have control over certain aspects of the operation, such as adjusting the speed or handling delicate items manually, which can be beneficial in industries where precision is crucial. On the other hand, full-automatic belting machines are designed to operate with minimal human intervention. These machines are equipped with advanced sensors and control systems that allow them to perform complex tasks with high precision and efficiency. Full-automatic machines are ideal for large-scale operations where the volume of goods being processed is high, and the need for speed and accuracy is paramount. They are commonly used in industries such as automotive manufacturing, where the consistency and reliability of the belting process are critical to the overall production line. The investment in full-automatic machines is justified by the significant increase in productivity and reduction in labor costs they offer. These machines are capable of running continuously, which maximizes throughput and minimizes downtime. The choice between semi-automatic and full-automatic belting machines depends on several factors, including the size of the operation, the type of materials being handled, and the level of automation desired. Businesses must carefully evaluate their needs and resources to determine which type of machine will best meet their requirements. As technology continues to advance, the line between semi-automatic and full-automatic machines is becoming increasingly blurred, with many modern machines offering a combination of both features. This hybrid approach allows businesses to benefit from the flexibility of semi-automatic machines while still enjoying the efficiency and precision of full-automatic systems. The Global Belting Machine Market is constantly evolving, with manufacturers continually developing new and innovative solutions to meet the changing needs of industries worldwide. Whether a business chooses a semi-automatic or full-automatic machine, the key is to select a system that aligns with their operational goals and provides the best return on investment.

Logistics, Manufacturing, Pharmaceutical, Others in the Global Belting Machine Market:

The Global Belting Machine Market finds extensive usage across various sectors, including logistics, manufacturing, pharmaceuticals, and others, each benefiting uniquely from these machines. In logistics, belting machines are indispensable for streamlining the movement of goods within warehouses and distribution centers. They facilitate the efficient handling of packages, reducing the time and labor required for manual sorting and transportation. This efficiency is crucial in logistics, where speed and accuracy directly impact customer satisfaction and operational costs. Belting machines in logistics are often integrated with advanced tracking systems, allowing for real-time monitoring and management of goods, which enhances the overall supply chain efficiency. In the manufacturing sector, belting machines play a pivotal role in automating production lines. They are used to transport raw materials, components, and finished products between different stages of the manufacturing process. This automation not only speeds up production but also ensures consistency and quality by minimizing human error. In industries such as automotive and electronics, where precision and reliability are paramount, belting machines are essential for maintaining high standards of production. The pharmaceutical industry also relies heavily on belting machines for the safe and efficient handling of delicate products. These machines are used to transport pharmaceutical products through various stages of production, packaging, and distribution. The precision and control offered by belting machines are crucial in this sector, where even minor errors can have significant consequences. Additionally, belting machines in the pharmaceutical industry are often designed to meet stringent hygiene and safety standards, ensuring that products are handled in a clean and controlled environment. Beyond these primary sectors, belting machines are also used in a variety of other industries, including food and beverage, mining, and agriculture. In the food and beverage industry, belting machines are used to transport ingredients and finished products through processing and packaging lines, ensuring that they are handled safely and efficiently. In mining, belting machines are used to transport raw materials from extraction sites to processing facilities, reducing the need for manual labor and improving safety. In agriculture, belting machines are used to automate the handling of crops and other agricultural products, increasing efficiency and reducing the reliance on manual labor. Overall, the Global Belting Machine Market is characterized by its versatility and adaptability, with machines designed to meet the specific needs of different industries. As technology continues to advance, the capabilities of belting machines are expected to expand, offering even greater efficiency and precision in material handling and processing.

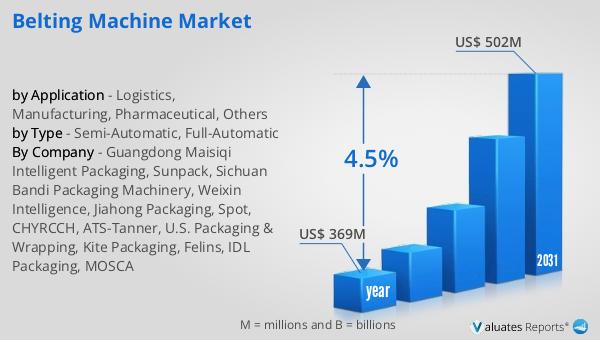

Global Belting Machine Market Outlook:

The global market for belting machines was valued at approximately $369 million in 2024, reflecting its significant role in various industrial sectors. This market is anticipated to grow steadily, reaching an estimated value of $502 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.5% over the forecast period. The steady increase in market size underscores the growing demand for automation and efficiency in industries such as manufacturing, logistics, and pharmaceuticals. As businesses continue to seek ways to optimize their operations and reduce costs, the adoption of belting machines is expected to rise. These machines offer numerous benefits, including increased productivity, reduced labor costs, and improved accuracy and consistency in material handling and processing. The projected growth of the belting machine market is also driven by advancements in technology, which have led to the development of more sophisticated and efficient machines. As industries continue to evolve and modernize, the demand for belting machines is likely to increase, making it a key area of interest for manufacturers and investors. The market's growth is further supported by the increasing focus on sustainability and energy efficiency, with many companies seeking to reduce their environmental impact through the use of more efficient machinery. Overall, the global belting machine market is poised for continued growth, driven by the increasing demand for automation and efficiency in various industries.

| Report Metric | Details |

| Report Name | Belting Machine Market |

| Accounted market size in year | US$ 369 million |

| Forecasted market size in 2031 | US$ 502 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Guangdong Maisiqi Intelligent Packaging, Sunpack, Sichuan Bandi Packaging Machinery, Weixin Intelligence, Jiahong Packaging, Spot, CHYRCCH, ATS-Tanner, U.S. Packaging & Wrapping, Kite Packaging, Felins, IDL Packaging, MOSCA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |