What is Global Alumina Ceramic Heaters Market?

The Global Alumina Ceramic Heaters Market is a specialized segment within the broader heating technology industry, focusing on the production and application of heaters made from alumina ceramic materials. Alumina ceramic heaters are known for their exceptional thermal conductivity, electrical insulation, and resistance to high temperatures, making them ideal for a variety of applications. These heaters are used in industries ranging from automotive to household appliances, where precise and efficient heating is required. The market is driven by the increasing demand for energy-efficient and durable heating solutions, as well as advancements in ceramic technology that enhance the performance and lifespan of these heaters. With the growing emphasis on sustainability and energy conservation, alumina ceramic heaters are gaining popularity due to their ability to provide consistent heat while minimizing energy consumption. The market is characterized by a mix of established players and emerging companies, each striving to innovate and capture a larger share of this expanding market. As industries continue to seek reliable and efficient heating solutions, the Global Alumina Ceramic Heaters Market is poised for steady growth, driven by technological advancements and the increasing adoption of ceramic heaters across various sectors.

Rod Type, Plate Type, Tube Type, Others in the Global Alumina Ceramic Heaters Market:

In the Global Alumina Ceramic Heaters Market, different types of heaters are categorized based on their design and application, including Rod Type, Plate Type, Tube Type, and Others. Each type has unique characteristics that make it suitable for specific uses. Rod Type alumina ceramic heaters are cylindrical and are often used in applications requiring concentrated heat in a small area. They are commonly found in industrial settings where precise heating is necessary, such as in the manufacturing of electronic components or in laboratory equipment. The design of rod heaters allows for efficient heat transfer and uniform temperature distribution, making them ideal for applications where consistent heat is crucial. Plate Type alumina ceramic heaters, on the other hand, are flat and are typically used in applications where a larger surface area needs to be heated. These heaters are often used in household appliances like toasters and hair straighteners, where even heat distribution across a flat surface is essential. The flat design of plate heaters allows for quick heating and cooling, making them energy-efficient and suitable for applications requiring rapid temperature changes. Tube Type alumina ceramic heaters are hollow and are used in applications where heat needs to be applied to a fluid or gas passing through the tube. These heaters are commonly used in industrial processes such as chemical processing or in heating systems where fluids need to be maintained at a specific temperature. The tubular design allows for efficient heat transfer to the fluid or gas, ensuring consistent temperature control. Other types of alumina ceramic heaters include custom-designed heaters that are tailored to specific applications. These can include heaters with unique shapes or configurations designed to fit specific equipment or to meet particular heating requirements. The versatility of alumina ceramic as a material allows for a wide range of customizations, making it possible to design heaters that meet the exact needs of different industries. Overall, the diversity of heater types within the Global Alumina Ceramic Heaters Market reflects the wide range of applications and industries that rely on these efficient and durable heating solutions.

Automotive Components, Household Heating Components, Industrial Heating Components, Others in the Global Alumina Ceramic Heaters Market:

The usage of Global Alumina Ceramic Heaters Market spans across various sectors, including Automotive Components, Household Heating Components, Industrial Heating Components, and Others. In the automotive industry, alumina ceramic heaters are used in components such as engine heaters, seat heaters, and defrosting systems. Their ability to provide rapid and consistent heat makes them ideal for automotive applications where quick temperature adjustments are necessary. The durability and efficiency of alumina ceramic heaters also contribute to their popularity in the automotive sector, as they can withstand the harsh conditions often encountered in vehicles. In household heating components, alumina ceramic heaters are commonly found in appliances like hair dryers, toasters, and space heaters. Their ability to provide even heat distribution and rapid heating makes them suitable for household applications where user comfort and energy efficiency are important. The use of alumina ceramic heaters in household appliances also contributes to energy savings, as they require less energy to achieve the desired temperature compared to traditional heating elements. In industrial heating components, alumina ceramic heaters are used in a variety of applications, including manufacturing processes, laboratory equipment, and chemical processing. Their high thermal conductivity and resistance to high temperatures make them ideal for industrial applications where precise temperature control is essential. The durability of alumina ceramic heaters also makes them suitable for use in harsh industrial environments, where they can withstand exposure to chemicals and high temperatures without degrading. Other applications of alumina ceramic heaters include medical devices, where they are used in equipment such as sterilizers and incubators, and in the electronics industry, where they are used in soldering and reflow processes. The versatility and efficiency of alumina ceramic heaters make them a valuable component in a wide range of applications, contributing to their growing popularity across various industries.

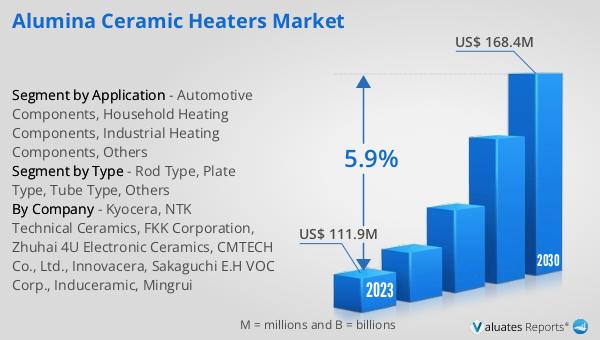

Global Alumina Ceramic Heaters Market Outlook:

The global market for Alumina Ceramic Heaters was valued at approximately $126 million in 2024 and is anticipated to grow to around $187 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.9% over the forecast period. This growth is driven by the increasing demand for efficient and durable heating solutions across various industries. The market is dominated by a few key players, with the top three companies accounting for about 67% of the market share. This concentration of market power highlights the competitive nature of the industry, where leading companies are continuously innovating to maintain their market position. Japan emerges as the largest producer of alumina ceramic heaters, contributing approximately 57% of the global production. This dominance can be attributed to Japan's advanced manufacturing capabilities and technological expertise in ceramic materials. Following Japan, China holds a significant share of about 19%, reflecting its growing influence in the global market. The presence of these major players and the geographical distribution of production underscore the strategic importance of the Asia-Pacific region in the alumina ceramic heaters market. As the market continues to evolve, companies are likely to focus on expanding their product offerings and enhancing their production capabilities to meet the increasing demand for high-performance heating solutions.

| Report Metric | Details |

| Report Name | Alumina Ceramic Heaters Market |

| Accounted market size in year | US$ 126 million |

| Forecasted market size in 2031 | US$ 187 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kyocera, NTK Technical Ceramics, FKK Corporation, Zhuhai 4U Electronic Ceramics, CMTECH Co., Ltd., Innovacera, Sakaguchi E.H VOC Corp., Induceramic, Mingrui, Korea Material Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |