What is Global 5 Axis Dental Milling Machine Market?

The Global 5 Axis Dental Milling Machine Market is a specialized segment within the broader dental equipment industry, focusing on advanced milling machines used for creating dental prosthetics. These machines are pivotal in the dental field as they allow for the precise and efficient production of dental crowns, bridges, and other prosthetic components. The "5 axis" in their name refers to the machine's ability to move a tool or a part along five different axes simultaneously, which is crucial for crafting complex shapes and surfaces with high accuracy. This capability is particularly important in dentistry, where the fit and finish of prosthetics must be perfect to ensure patient comfort and functionality. The market for these machines is driven by the increasing demand for dental restorations, advancements in dental technology, and the growing adoption of digital dentistry practices. As dental professionals seek to improve patient outcomes and streamline their workflows, the demand for 5 axis dental milling machines is expected to grow. These machines not only enhance the precision of dental restorations but also reduce the time required to produce them, making them an invaluable tool in modern dental practices.

Vertical, Horizontal in the Global 5 Axis Dental Milling Machine Market:

In the Global 5 Axis Dental Milling Machine Market, machines are categorized based on their orientation and design, primarily into vertical and horizontal configurations. Vertical milling machines are characterized by their vertical spindle orientation, which allows the cutting tool to move vertically along the workpiece. This design is particularly advantageous for tasks that require precision and detail, such as creating intricate dental prosthetics. Vertical machines are often favored in dental labs and clinics where space is limited, as they tend to have a smaller footprint compared to their horizontal counterparts. They are also generally easier to set up and operate, making them a popular choice for dental professionals who may not have extensive technical expertise. On the other hand, horizontal milling machines have a horizontal spindle orientation, which allows the cutting tool to move horizontally across the workpiece. This configuration is ideal for tasks that require heavy cutting and material removal, as the horizontal design provides greater stability and support for the workpiece. Horizontal machines are often used in larger dental labs and manufacturing facilities where space is not a constraint, and where the focus is on high-volume production. These machines are typically more robust and capable of handling larger and heavier workpieces, making them suitable for producing a wide range of dental prosthetics. The choice between vertical and horizontal milling machines in the dental industry often depends on the specific needs and requirements of the dental practice or lab. For smaller clinics and labs that focus on custom, low-volume production, vertical machines may be more suitable due to their compact size and ease of use. In contrast, larger facilities that require high-volume production and have the space to accommodate larger equipment may opt for horizontal machines to take advantage of their increased capacity and efficiency. Both vertical and horizontal milling machines play a crucial role in the Global 5 Axis Dental Milling Machine Market, providing dental professionals with the tools they need to produce high-quality dental restorations. As the demand for dental prosthetics continues to grow, the market for these machines is expected to expand, driven by advancements in technology and the increasing adoption of digital dentistry practices. Whether vertical or horizontal, these machines are essential for modern dental practices, enabling them to deliver precise and efficient dental restorations to their patients.

Dental Clinic, Dental Hospital, Dental Service Organization, Dental Lab in the Global 5 Axis Dental Milling Machine Market:

The Global 5 Axis Dental Milling Machine Market finds its application across various sectors within the dental industry, including dental clinics, dental hospitals, dental service organizations, and dental labs. In dental clinics, these machines are used to produce custom dental prosthetics on-site, allowing dentists to offer same-day restorations to their patients. This capability is particularly beneficial for patients who require immediate dental work, as it eliminates the need for multiple visits and reduces the overall treatment time. By using 5 axis milling machines, dental clinics can enhance their service offerings and improve patient satisfaction by providing high-quality, precise restorations in a timely manner. Dental hospitals, which often handle more complex and diverse cases, also benefit from the use of 5 axis dental milling machines. These machines enable dental hospitals to produce a wide range of prosthetics, from simple crowns to complex bridges and implants, with high precision and accuracy. The ability to produce custom prosthetics in-house allows dental hospitals to streamline their workflows and reduce reliance on external suppliers, ultimately improving efficiency and reducing costs. Dental service organizations, which manage multiple dental practices, can leverage 5 axis milling machines to standardize the production of dental prosthetics across their network. By centralizing the production process, these organizations can ensure consistent quality and reduce variability in the prosthetics provided to patients. This approach not only enhances the overall quality of care but also allows dental service organizations to achieve economies of scale, reducing costs and improving profitability. Dental labs, which specialize in the production of dental prosthetics, are perhaps the most significant users of 5 axis dental milling machines. These labs rely on the advanced capabilities of these machines to produce a wide range of prosthetics with high precision and efficiency. By using 5 axis milling machines, dental labs can offer a diverse array of products to dental professionals, from simple crowns and bridges to complex implant-supported restorations. The ability to produce high-quality prosthetics quickly and efficiently allows dental labs to meet the growing demand for dental restorations and maintain a competitive edge in the market. Overall, the Global 5 Axis Dental Milling Machine Market plays a crucial role in the dental industry, providing the tools and technology needed to produce high-quality dental prosthetics across various sectors. As the demand for dental restorations continues to grow, the adoption of 5 axis milling machines is expected to increase, driven by the need for precision, efficiency, and improved patient outcomes.

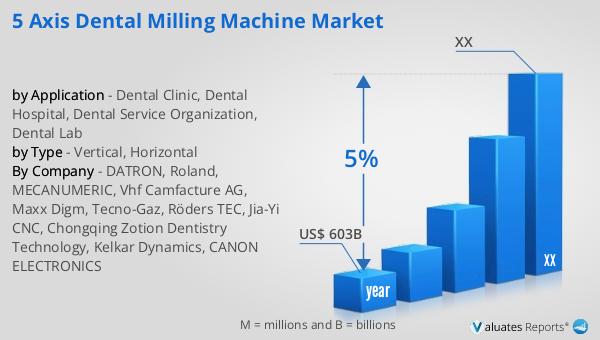

Global 5 Axis Dental Milling Machine Market Outlook:

Based on our research, the global market for medical devices, which includes the Global 5 Axis Dental Milling Machine Market, is projected to reach approximately $603 billion in 2023. This substantial market size underscores the growing importance of medical devices in healthcare, driven by technological advancements and increasing demand for innovative solutions. Over the next six years, the market is expected to grow at a compound annual growth rate (CAGR) of 5%. This steady growth rate reflects the ongoing expansion and development within the medical device industry, as companies continue to innovate and introduce new products to meet the evolving needs of healthcare providers and patients. The Global 5 Axis Dental Milling Machine Market is a key component of this broader market, contributing to the overall growth and development of the medical device sector. As dental professionals increasingly adopt digital dentistry practices and seek to improve patient outcomes, the demand for advanced milling machines is expected to rise. This growth is further supported by the increasing prevalence of dental disorders and the growing awareness of the importance of oral health. As a result, the Global 5 Axis Dental Milling Machine Market is poised for continued expansion, driven by the need for precision, efficiency, and improved patient care in the dental industry.

| Report Metric | Details |

| Report Name | 5 Axis Dental Milling Machine Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DATRON, Roland, MECANUMERIC, Vhf Camfacture AG, Maxx Digm, Tecno-Gaz, Röders TEC, Jia-Yi CNC, Chongqing Zotion Dentistry Technology, Kelkar Dynamics, CANON ELECTRONICS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |