What is Global PET Preform Making Equipment Market?

The Global PET Preform Making Equipment Market is a specialized sector within the broader manufacturing industry, focusing on the production of preforms made from polyethylene terephthalate (PET). These preforms are essentially the initial stage in the production of PET bottles and containers, which are widely used across various industries due to their lightweight, durable, and recyclable nature. The equipment used in this market is designed to produce preforms with precision and efficiency, ensuring that they meet the specific requirements of different applications. The market is driven by the increasing demand for PET bottles in sectors such as beverages, personal care, and consumer goods, where the need for sustainable and cost-effective packaging solutions is paramount. Technological advancements in machinery, such as improved energy efficiency and automation, are also contributing to the growth of this market. As environmental concerns continue to rise, the PET preform making equipment market is expected to evolve, focusing on innovations that enhance recyclability and reduce carbon footprints. This market plays a crucial role in the supply chain of many industries, providing the essential components needed for the production of PET containers.

Hydraulic, Electric, Hybrid in the Global PET Preform Making Equipment Market:

The Global PET Preform Making Equipment Market is characterized by the use of three main types of machinery: hydraulic, electric, and hybrid. Each type has its own set of advantages and is chosen based on specific production needs and efficiency requirements. Hydraulic machines have been the traditional choice in the industry due to their robustness and ability to handle large-scale production. They operate using hydraulic cylinders and pumps, which provide the force needed to mold the PET preforms. These machines are known for their durability and ability to produce high-quality preforms consistently. However, they tend to consume more energy compared to their electric counterparts, which has led to a gradual shift in preference towards more energy-efficient solutions. Electric PET preform making machines have gained popularity in recent years due to their energy efficiency and precision. Unlike hydraulic machines, electric machines use electric motors to drive the molding process, which significantly reduces energy consumption and operational costs. They offer precise control over the molding process, resulting in higher quality preforms with minimal defects. Additionally, electric machines are quieter and require less maintenance, making them an attractive option for manufacturers looking to optimize their production processes. The initial investment for electric machines may be higher, but the long-term savings in energy and maintenance costs often justify the expense. Hybrid machines combine the best features of both hydraulic and electric systems, offering a balanced solution for PET preform production. These machines use a combination of hydraulic and electric components to optimize performance and energy efficiency. The hydraulic system provides the necessary force for molding, while the electric system ensures precise control and energy savings. Hybrid machines are particularly beneficial for manufacturers who require the robustness of hydraulic systems but also want to take advantage of the energy efficiency and precision offered by electric machines. They offer flexibility in production, allowing manufacturers to adapt to varying production demands and optimize their operations. The choice between hydraulic, electric, and hybrid machines depends on several factors, including production volume, energy costs, and specific application requirements. Manufacturers must carefully evaluate their needs and consider the long-term benefits of each type of machine. As the demand for PET preforms continues to grow, driven by the increasing use of PET bottles in various industries, the market for PET preform making equipment is expected to evolve. Technological advancements and innovations in machine design will likely focus on improving energy efficiency, reducing environmental impact, and enhancing the overall quality of PET preforms. This evolution will provide manufacturers with more options and opportunities to optimize their production processes and meet the growing demand for sustainable packaging solutions.

Consumer Goods, Personal Care & Cosmetics, Bottled Water & Beverages, Others in the Global PET Preform Making Equipment Market:

The Global PET Preform Making Equipment Market finds extensive usage across various sectors, including consumer goods, personal care and cosmetics, bottled water and beverages, and others. In the consumer goods sector, PET preforms are used to produce a wide range of packaging solutions for products such as household cleaners, detergents, and food containers. The lightweight and durable nature of PET bottles makes them an ideal choice for packaging consumer goods, as they are easy to handle and transport. Additionally, the recyclability of PET materials aligns with the growing consumer demand for sustainable packaging options, further driving the use of PET preforms in this sector. In the personal care and cosmetics industry, PET preforms are used to create packaging for products such as shampoos, conditioners, lotions, and creams. The clarity and aesthetic appeal of PET bottles make them a popular choice for cosmetic packaging, as they allow consumers to see the product inside. Moreover, PET bottles provide excellent barrier properties, protecting the contents from external factors such as moisture and oxygen, which can degrade the quality of cosmetic products. The versatility of PET preforms allows manufacturers to create a variety of shapes and sizes, catering to the diverse packaging needs of the personal care and cosmetics industry. The bottled water and beverages sector is one of the largest consumers of PET preforms, accounting for a significant portion of the market. PET bottles are widely used for packaging water, soft drinks, juices, and other beverages due to their lightweight, shatter-resistant, and recyclable properties. The demand for bottled water and beverages continues to grow globally, driven by factors such as urbanization, changing consumer lifestyles, and increasing health consciousness. This growth directly impacts the demand for PET preforms, as manufacturers seek efficient and cost-effective solutions for producing high-quality beverage containers. Beyond these primary sectors, PET preforms are also used in other industries, such as pharmaceuticals and chemicals, where they serve as packaging for various liquid and solid products. The adaptability of PET preforms to different applications makes them a versatile choice for manufacturers across multiple industries. As environmental concerns and regulations continue to shape the packaging landscape, the demand for sustainable and recyclable packaging solutions like PET preforms is expected to rise. This trend will likely drive further innovation and development in the PET preform making equipment market, enabling manufacturers to meet the evolving needs of their customers and contribute to a more sustainable future.

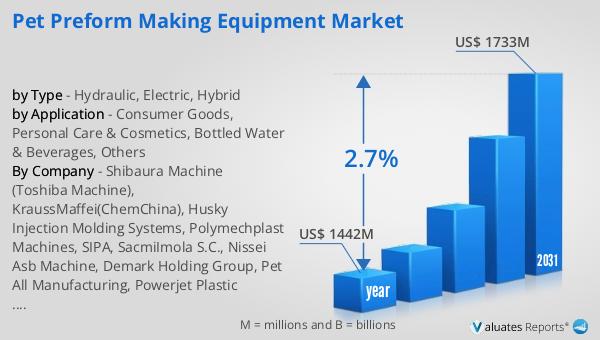

Global PET Preform Making Equipment Market Outlook:

In 2024, the global market for PET Preform Making Equipment was valued at approximately $1,442 million. By 2031, it is anticipated to expand to a revised size of around $1,733 million, reflecting a compound annual growth rate (CAGR) of 2.7% over the forecast period. The bottled water and beverages sector emerged as the predominant user of PET preforms, accounting for about 74% of the global consumption in 2019. This significant share underscores the critical role that PET preforms play in the packaging of beverages, driven by their lightweight, durable, and recyclable properties. The Asia Pacific region was a major contributor to the global market, capturing 60% of the market share in 2019. This dominance can be attributed to the region's rapid industrialization, urbanization, and growing consumer base, which have fueled the demand for PET bottles and containers. As the market continues to evolve, manufacturers are likely to focus on enhancing the efficiency and sustainability of PET preform making equipment to meet the increasing demand for eco-friendly packaging solutions. The ongoing advancements in technology and machinery design will play a crucial role in shaping the future of the PET preform making equipment market, providing manufacturers with the tools they need to optimize their production processes and cater to the diverse needs of their customers.

| Report Metric | Details |

| Report Name | PET Preform Making Equipment Market |

| Accounted market size in year | US$ 1442 million |

| Forecasted market size in 2031 | US$ 1733 million |

| CAGR | 2.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shibaura Machine (Toshiba Machine), KraussMaffei(ChemChina), Husky Injection Molding Systems, Polymechplast Machines, SIPA, SacmiImola S.C., Nissei Asb Machine, Demark Holding Group, Pet All Manufacturing, Powerjet Plastic Machinery, CYPET Technologies, Jon Wai Machinery Works, Magnum Group, Ningbo Hautek Industries Co.,Ltd., Hisson Plastic Machinery Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |