What is Global Medical Grade Thermoplastic Vulcanizate Market?

The Global Medical Grade Thermoplastic Vulcanizate (TPV) Market is a specialized segment within the broader thermoplastic elastomers market, focusing on materials used in medical applications. TPVs are a type of thermoplastic elastomer that combines the properties of rubber with the processing advantages of plastics. This unique combination makes them highly desirable in the medical field, where flexibility, durability, and biocompatibility are crucial. Medical grade TPVs are specifically formulated to meet stringent regulatory standards and are used in various medical devices and components. They offer excellent resistance to chemicals, sterilization processes, and wear and tear, making them ideal for use in environments where hygiene and reliability are paramount. The global market for these materials is driven by the increasing demand for advanced medical devices and the growing emphasis on patient safety and comfort. As healthcare systems worldwide continue to evolve, the need for innovative materials like medical grade TPVs is expected to rise, supporting the development of new and improved medical technologies. This market is characterized by ongoing research and development efforts aimed at enhancing the performance and versatility of TPVs to meet the ever-changing needs of the medical industry.

Injection Molding Grade, Blowing Injection Grade, Extrusion Grade in the Global Medical Grade Thermoplastic Vulcanizate Market:

In the Global Medical Grade Thermoplastic Vulcanizate Market, different grades of TPVs are tailored to specific manufacturing processes and applications, each offering unique properties and benefits. Injection molding grade TPVs are designed for use in injection molding processes, which involve injecting molten material into a mold to create complex shapes and components. These grades are known for their excellent flow characteristics, allowing them to fill intricate molds with precision. This makes them ideal for producing detailed medical device components that require high dimensional accuracy and consistency. Injection molding grade TPVs also offer good mechanical properties, such as flexibility and impact resistance, which are essential for medical applications where durability and patient comfort are critical.

Drug Delivery Syringe, Medical Device Components, Medical Packaging Components in the Global Medical Grade Thermoplastic Vulcanizate Market:

Blowing injection grade TPVs are specifically formulated for blow molding processes, where air pressure is used to inflate soft plastic into a mold cavity. This technique is commonly used to produce hollow parts, such as medical tubing and containers. Blowing injection grade TPVs are valued for their ability to create lightweight, flexible, and durable products that can withstand repeated use and sterilization. These materials are also resistant to a wide range of chemicals, making them suitable for applications where exposure to various substances is common. The versatility of blowing injection grade TPVs allows manufacturers to produce a wide array of medical components with varying shapes and sizes, catering to the diverse needs of the healthcare industry.

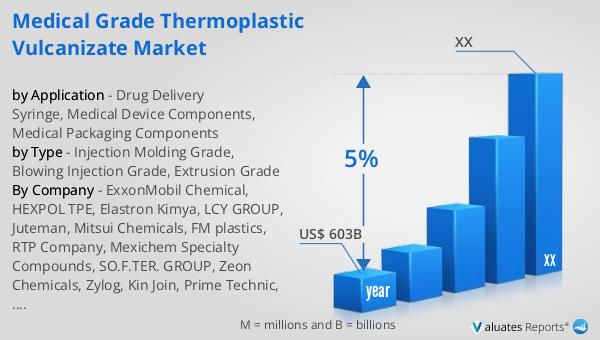

Global Medical Grade Thermoplastic Vulcanizate Market Outlook:

Extrusion grade TPVs are designed for extrusion processes, where material is forced through a die to create continuous shapes, such as sheets, tubes, and profiles. These grades are characterized by their excellent processability and ability to maintain consistent quality over long production runs. Extrusion grade TPVs are commonly used in the production of medical tubing, gaskets, and seals, where flexibility, strength, and chemical resistance are essential. The ability to produce long, continuous lengths of material makes extrusion grade TPVs ideal for applications that require seamless components, such as catheters and other medical devices that come into direct contact with the human body. The adaptability of extrusion grade TPVs allows manufacturers to create customized solutions that meet the specific requirements of different medical applications, ensuring optimal performance and patient safety.

| Report Metric | Details |

| Report Name | Medical Grade Thermoplastic Vulcanizate Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ExxonMobil Chemical, HEXPOL TPE, Elastron Kimya, LCY GROUP, Juteman, Mitsui Chemicals, FM plastics, RTP Company, Mexichem Specialty Compounds, SO.F.TER. GROUP, Zeon Chemicals, Zylog, Kin Join, Prime Technic, GAINSHINE, Synotech Polymers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |