What is Global Leafing Aluminum Powder Market?

The Global Leafing Aluminum Powder Market is a specialized segment within the broader aluminum powder industry. Leafing aluminum powder is a fine, metallic pigment that is used primarily for its reflective and decorative properties. It is produced by milling aluminum into a fine powder and then treating it to create a leafing effect, where the particles float to the surface of a coating, creating a shiny, metallic finish. This type of aluminum powder is widely used in various industries, including coatings, inks, and plastics, due to its ability to provide a brilliant, reflective surface. The market for leafing aluminum powder is driven by its demand in the automotive and construction industries, where it is used to enhance the aesthetic appeal and durability of products. Additionally, the growing trend towards eco-friendly and sustainable products has led to increased interest in aluminum powders, as they are recyclable and have a lower environmental impact compared to other metallic pigments. The market is characterized by a few key players who dominate the industry, but there is also room for smaller companies to innovate and capture niche markets. Overall, the Global Leafing Aluminum Powder Market is poised for steady growth as industries continue to seek out high-quality, sustainable materials for their products.

Floating Aluminum Powder, Non Floating Aluminum Powder in the Global Leafing Aluminum Powder Market:

Floating aluminum powder and non-floating aluminum powder are two distinct types of aluminum powders that serve different purposes within the Global Leafing Aluminum Powder Market. Floating aluminum powder, also known as leafing aluminum powder, is designed to rise to the surface of a liquid medium, such as paint or ink, and form a continuous, reflective layer. This property is achieved through the use of specific additives during the manufacturing process, which cause the aluminum particles to repel each other and float to the top. The result is a brilliant, metallic finish that is highly sought after in applications where aesthetics are important, such as automotive coatings and decorative paints. Floating aluminum powder is also used in the production of metallic inks for printing, where it provides a shiny, reflective surface that enhances the visual appeal of printed materials. On the other hand, non-floating aluminum powder, also known as non-leafing aluminum powder, is designed to remain evenly dispersed throughout a liquid medium. This type of aluminum powder is used in applications where a uniform appearance is desired, such as in industrial coatings and plastics. Non-floating aluminum powder is often used in combination with other pigments to create a wide range of colors and finishes. It is also used in the production of lightweight, high-strength materials, such as aluminum foams and composites, where its unique properties contribute to the overall performance of the material. The choice between floating and non-floating aluminum powder depends on the specific requirements of the application, including factors such as appearance, durability, and cost. Both types of aluminum powders are widely used in the Global Leafing Aluminum Powder Market, and their demand is driven by the growing need for high-quality, sustainable materials in various industries. As the market continues to evolve, manufacturers are investing in research and development to improve the performance and sustainability of their products, leading to new innovations and opportunities for growth.

Coating, Automobile, Other in the Global Leafing Aluminum Powder Market:

The Global Leafing Aluminum Powder Market finds its applications in various sectors, with coatings, automobiles, and other industries being the primary areas of usage. In the coatings industry, leafing aluminum powder is prized for its ability to create a reflective, metallic finish that enhances the aesthetic appeal of products. It is commonly used in automotive coatings, where it provides a shiny, metallic look that is both attractive and durable. The reflective properties of leafing aluminum powder also make it an ideal choice for protective coatings, as it can help to deflect heat and UV radiation, thereby extending the lifespan of the coated surface. In the automotive industry, leafing aluminum powder is used in a variety of applications, from exterior paints to interior finishes. Its ability to create a high-gloss, metallic finish makes it a popular choice for car manufacturers looking to enhance the visual appeal of their vehicles. Additionally, the lightweight nature of aluminum powder makes it an attractive option for use in lightweight, high-strength materials, such as aluminum foams and composites, which are used in the production of automotive components. Beyond coatings and automobiles, leafing aluminum powder is also used in a range of other industries, including printing, plastics, and construction. In the printing industry, it is used to create metallic inks that provide a shiny, reflective surface, enhancing the visual appeal of printed materials. In the plastics industry, leafing aluminum powder is used to create metallic finishes on plastic products, adding a touch of elegance and sophistication. In the construction industry, it is used in the production of lightweight, high-strength materials, such as aluminum foams and composites, which are used in a variety of applications, from building facades to insulation. Overall, the Global Leafing Aluminum Powder Market is characterized by its versatility and wide range of applications, making it an essential component in many industries.

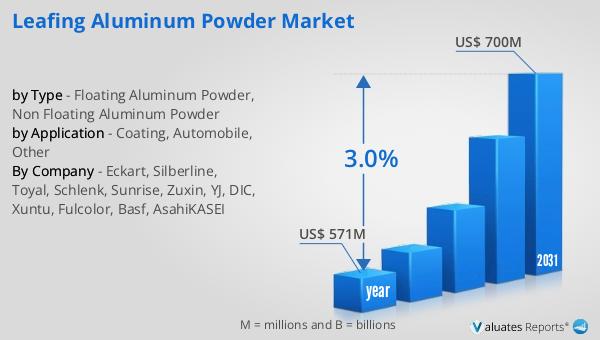

Global Leafing Aluminum Powder Market Outlook:

The global market for Leafing Aluminum Powder was valued at $571 million in 2024 and is expected to grow to a revised size of $700 million by 2031, with a compound annual growth rate (CAGR) of 3.0% during the forecast period. This growth is driven by the increasing demand for high-quality, sustainable materials in various industries, including automotive, construction, and coatings. The reflective and decorative properties of leafing aluminum powder make it an attractive option for manufacturers looking to enhance the aesthetic appeal and durability of their products. Additionally, the growing trend towards eco-friendly and sustainable products has led to increased interest in aluminum powders, as they are recyclable and have a lower environmental impact compared to other metallic pigments. The market is characterized by a few key players who dominate the industry, but there is also room for smaller companies to innovate and capture niche markets. As the market continues to evolve, manufacturers are investing in research and development to improve the performance and sustainability of their products, leading to new innovations and opportunities for growth. Overall, the Global Leafing Aluminum Powder Market is poised for steady growth as industries continue to seek out high-quality, sustainable materials for their products.

| Report Metric | Details |

| Report Name | Leafing Aluminum Powder Market |

| Accounted market size in year | US$ 571 million |

| Forecasted market size in 2031 | US$ 700 million |

| CAGR | 3.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Eckart, Silberline, Toyal, Schlenk, Sunrise, Zuxin, YJ, DIC, Xuntu, Fulcolor, Basf, AsahiKASEI |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |