What is Global Centerless Grinding Equipment Market?

The Global Centerless Grinding Equipment Market is a specialized segment within the broader machinery industry, focusing on equipment that grinds the outer surface of a workpiece without the need for a spindle or fixture to hold the workpiece in place. This type of grinding is particularly useful for producing cylindrical parts with high precision and efficiency. Centerless grinding equipment is widely used in various industries, including automotive, aerospace, and engineering machinery, due to its ability to produce smooth and accurate finishes on metal parts. The market for this equipment is driven by the increasing demand for precision components in these industries, as well as advancements in technology that have improved the efficiency and capabilities of grinding machines. Manufacturers in this market are continually innovating to meet the evolving needs of their customers, offering machines that are more versatile, energy-efficient, and capable of handling a wider range of materials. As industries continue to demand higher precision and efficiency, the global centerless grinding equipment market is expected to grow, providing opportunities for manufacturers and suppliers to expand their offerings and reach new customers.

Universal type, Special type, Precise type, Others in the Global Centerless Grinding Equipment Market:

The Global Centerless Grinding Equipment Market can be categorized into several types, each serving specific needs and applications. The Universal type of centerless grinding equipment is designed to handle a wide range of grinding tasks, making it highly versatile and suitable for various industries. These machines are capable of performing both in-feed and through-feed grinding, allowing them to process different shapes and sizes of workpieces. They are often used in applications where flexibility and adaptability are crucial, such as in job shops and small manufacturing facilities. On the other hand, the Special type of centerless grinding equipment is tailored for specific applications or industries. These machines are designed to meet the unique requirements of particular tasks, such as grinding complex shapes or materials that are difficult to process with standard equipment. Special type machines often incorporate advanced features and technologies to enhance their performance and efficiency, making them ideal for high-precision applications in industries like aerospace and medical device manufacturing. The Precise type of centerless grinding equipment is focused on achieving the highest levels of accuracy and surface finish. These machines are equipped with advanced control systems and precision components to ensure consistent and repeatable results. They are commonly used in industries where precision is paramount, such as in the production of high-tolerance components for the automotive and aerospace sectors. Finally, the Others category includes various types of centerless grinding equipment that do not fit neatly into the previous categories. This can include machines designed for specific niche applications or those that incorporate unique features to address particular challenges. As the demand for precision and efficiency continues to grow across industries, manufacturers are developing new and innovative types of centerless grinding equipment to meet the diverse needs of their customers. Each type of machine offers distinct advantages and capabilities, allowing businesses to choose the equipment that best suits their specific requirements and operational goals.

Automobile Industry, Aerospace Industry, Engineering Machinery Industry, Others in the Global Centerless Grinding Equipment Market:

The Global Centerless Grinding Equipment Market plays a crucial role in several key industries, providing essential tools for manufacturing and production processes. In the Automobile Industry, centerless grinding equipment is used extensively to produce high-precision components such as shafts, bearings, and other cylindrical parts. These machines enable manufacturers to achieve the tight tolerances and smooth finishes required for automotive parts, ensuring optimal performance and reliability. The ability to produce large volumes of parts quickly and efficiently makes centerless grinding equipment an invaluable asset in the automotive sector, where demand for high-quality components is constantly increasing. In the Aerospace Industry, the need for precision and reliability is even more critical. Centerless grinding equipment is used to manufacture components that must withstand extreme conditions and meet stringent safety standards. These machines are essential for producing parts such as turbine blades, landing gear components, and other critical aerospace components. The high level of precision and consistency offered by centerless grinding equipment ensures that these parts meet the rigorous requirements of the aerospace industry, contributing to the safety and performance of aircraft. The Engineering Machinery Industry also relies heavily on centerless grinding equipment to produce a wide range of components used in various types of machinery and equipment. These machines are used to grind parts such as hydraulic cylinders, rollers, and other cylindrical components that require precise dimensions and smooth finishes. The versatility and efficiency of centerless grinding equipment make it an ideal choice for manufacturers in this industry, allowing them to produce high-quality components that meet the demands of their customers. In addition to these industries, centerless grinding equipment is used in various other sectors, including medical device manufacturing, electronics, and consumer goods. The ability to produce precise and consistent components is essential in these industries, where quality and reliability are paramount. As the demand for high-precision components continues to grow across various sectors, the Global Centerless Grinding Equipment Market is expected to expand, providing manufacturers with the tools they need to meet the evolving needs of their customers.

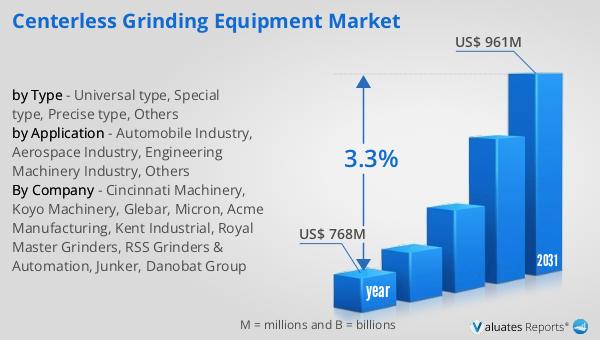

Global Centerless Grinding Equipment Market Outlook:

The global market for Centerless Grinding Equipment was valued at approximately $768 million in 2024, and it is anticipated to grow to a revised size of around $961 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.3% over the forecast period. This steady growth can be attributed to several factors, including the increasing demand for precision components in various industries such as automotive, aerospace, and engineering machinery. As these industries continue to evolve and require more advanced and precise components, the need for efficient and reliable grinding equipment becomes more critical. Additionally, advancements in technology have led to the development of more sophisticated and capable centerless grinding machines, further driving market growth. Manufacturers are focusing on enhancing the capabilities of their equipment to meet the diverse needs of their customers, offering machines that are more versatile, energy-efficient, and capable of handling a wider range of materials. As a result, the global centerless grinding equipment market is expected to continue its upward trajectory, providing opportunities for manufacturers and suppliers to expand their offerings and reach new customers. This growth also highlights the importance of innovation and adaptation in the industry, as companies strive to meet the evolving demands of their customers and maintain a competitive edge in the market.

| Report Metric | Details |

| Report Name | Centerless Grinding Equipment Market |

| Accounted market size in year | US$ 768 million |

| Forecasted market size in 2031 | US$ 961 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Cincinnati Machinery, Koyo Machinery, Glebar, Micron, Acme Manufacturing, Kent Industrial, Royal Master Grinders, RSS Grinders & Automation, Junker, Danobat Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |