What is Global Hypoallergenic Medical Tape Market?

The Global Hypoallergenic Medical Tape Market is a specialized segment within the broader medical supplies industry, focusing on tapes designed to minimize allergic reactions. These tapes are crucial for patients with sensitive skin or allergies, ensuring that medical procedures do not cause additional discomfort or complications. Hypoallergenic medical tapes are used in various applications, including wound care, surgical procedures, and securing medical devices like catheters and IV lines. They are made from materials that are less likely to cause skin irritation, such as silicone, acrylic, and other non-latex substances. The market for these tapes is driven by the increasing prevalence of chronic diseases, rising awareness about skin allergies, and the growing demand for advanced wound care products. Additionally, the aging population and the increasing number of surgeries worldwide contribute to the market's growth. The market is characterized by continuous innovation, with manufacturers focusing on developing tapes that offer better adhesion, breathability, and comfort. Overall, the Global Hypoallergenic Medical Tape Market plays a vital role in enhancing patient care and improving the quality of life for individuals with sensitive skin.

Transparent, Translucent, Opaque in the Global Hypoallergenic Medical Tape Market:

In the context of the Global Hypoallergenic Medical Tape Market, the terms transparent, translucent, and opaque refer to the different types of tapes available based on their visibility and material properties. Transparent hypoallergenic medical tapes are clear and allow for easy monitoring of the skin or wound underneath. These tapes are particularly useful in situations where healthcare providers need to observe the healing process without removing the tape, thereby reducing the risk of infection and skin irritation. Transparent tapes are often made from materials like polyurethane or polyethylene, which provide a good balance of strength and flexibility while being gentle on the skin. Translucent hypoallergenic medical tapes, on the other hand, are semi-clear and allow some light to pass through but do not provide a completely clear view of the skin or wound. These tapes offer a compromise between visibility and privacy, making them suitable for applications where some level of observation is needed without fully exposing the underlying area. Translucent tapes are typically made from materials like non-woven fabrics or certain types of plastics that offer good breathability and comfort. Opaque hypoallergenic medical tapes are completely non-transparent and do not allow any light to pass through. These tapes are used in situations where visibility is not a priority, and the focus is on providing strong adhesion and protection. Opaque tapes are often made from materials like cloth or foam, which offer excellent durability and cushioning. They are ideal for securing dressings, splints, or other medical devices that require a high level of support and stability. Each type of tape has its own set of advantages and is chosen based on the specific needs of the patient and the medical procedure. For instance, transparent tapes are preferred for post-surgical dressings where monitoring is crucial, while opaque tapes are used for securing bulky dressings or devices that need extra support. The choice between transparent, translucent, and opaque tapes also depends on factors like the patient's skin sensitivity, the duration of tape application, and the level of activity expected. In summary, the Global Hypoallergenic Medical Tape Market offers a variety of options to cater to different medical needs, ensuring that patients receive the best possible care while minimizing the risk of allergic reactions and skin irritation.

Medical, Household in the Global Hypoallergenic Medical Tape Market:

The usage of hypoallergenic medical tapes extends beyond the medical field and finds applications in household settings as well. In the medical field, these tapes are indispensable for wound care, surgical procedures, and securing medical devices. They are used to hold dressings in place, secure IV lines, and attach monitoring devices to the skin. The hypoallergenic nature of these tapes ensures that patients with sensitive skin or allergies do not experience adverse reactions, making them a preferred choice in hospitals, clinics, and home healthcare settings. For instance, during surgeries, hypoallergenic tapes are used to secure drapes and other surgical materials, ensuring that they stay in place without causing skin irritation. In wound care, these tapes are used to secure dressings and bandages, providing a protective barrier that helps in the healing process. They are also used in pediatric care, where the delicate skin of infants and children requires gentle yet effective adhesion. In household settings, hypoallergenic medical tapes are used for various first aid applications. They are ideal for securing bandages and dressings for minor cuts, scrapes, and burns. Their gentle adhesion makes them suitable for use on sensitive skin, ensuring that they do not cause discomfort or irritation. Additionally, these tapes can be used to secure splints or other supportive devices in case of minor injuries. They are also useful for securing medical devices like insulin pumps or continuous glucose monitors, which need to be attached to the skin for extended periods. The hypoallergenic properties of these tapes ensure that they can be worn comfortably without causing skin reactions. Furthermore, hypoallergenic medical tapes can be used for various non-medical applications around the house. For example, they can be used to secure loose items, create temporary repairs, or even for crafting purposes. Their gentle adhesion and easy removal make them a versatile tool for various household tasks. In summary, the usage of hypoallergenic medical tapes spans both medical and household settings, providing a reliable and skin-friendly solution for various applications. Whether used in hospitals, clinics, or homes, these tapes play a crucial role in ensuring patient comfort and care while minimizing the risk of allergic reactions and skin irritation.

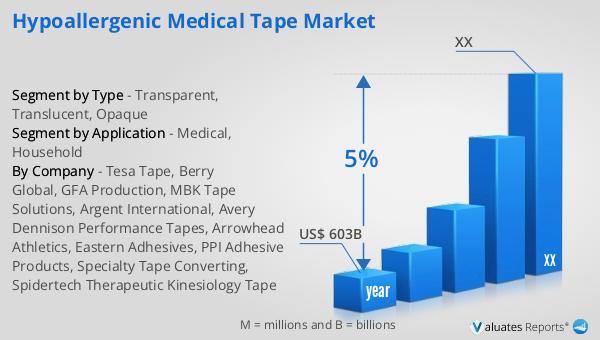

Global Hypoallergenic Medical Tape Market Outlook:

According to our research, the global market for medical devices is estimated at US$ 603 billion in the year 2023 and will be growing at a CAGR of 5% during the next six years. This indicates a robust and steady growth trajectory for the medical device industry, driven by factors such as technological advancements, increasing healthcare expenditure, and the rising prevalence of chronic diseases. The market's expansion is also fueled by the growing demand for innovative and efficient medical devices that can improve patient outcomes and streamline healthcare processes. As the healthcare landscape continues to evolve, the need for advanced medical devices that offer better diagnostics, treatment, and monitoring capabilities is becoming increasingly critical. This growth trend underscores the importance of continuous research and development in the medical device sector to meet the ever-changing needs of patients and healthcare providers. Additionally, the increasing adoption of digital health technologies and telemedicine is expected to further propel the market's growth, offering new opportunities for innovation and expansion. Overall, the projected growth of the global medical device market highlights the dynamic nature of the industry and its vital role in enhancing healthcare delivery worldwide.

| Report Metric | Details |

| Report Name | Hypoallergenic Medical Tape Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Tesa Tape, Berry Global, GFA Production, MBK Tape Solutions, Argent International, Avery Dennison Performance Tapes, Arrowhead Athletics, Eastern Adhesives, PPI Adhesive Products, Specialty Tape Converting, Spidertech Therapeutic Kinesiology Tape |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |