What is Global Stirling Cycle Cryogenic Coolers Market?

The Global Stirling Cycle Cryogenic Coolers Market is a specialized segment within the broader cryogenic technology industry. These coolers are based on the Stirling cycle, a thermodynamic process that is highly efficient for cooling applications. They are primarily used to achieve extremely low temperatures, which are essential for various scientific, medical, and industrial applications. The market for these coolers is driven by their ability to provide reliable and efficient cooling solutions without the need for complex and bulky refrigeration systems. Stirling cycle cryogenic coolers are known for their compact size, low vibration, and high reliability, making them ideal for sensitive applications where precision is crucial. The demand for these coolers is increasing as industries continue to seek advanced cooling technologies that can support cutting-edge research and development activities. As a result, the market is witnessing significant growth, with advancements in technology further enhancing the performance and efficiency of these coolers. The global market is characterized by a diverse range of applications, from space exploration to medical imaging, each requiring specific cooling capabilities that Stirling cycle cryogenic coolers can provide. This growing demand is expected to continue as industries expand their reliance on cryogenic technologies for various critical applications.

Split Type, Integral Type in the Global Stirling Cycle Cryogenic Coolers Market:

In the Global Stirling Cycle Cryogenic Coolers Market, there are two primary types of coolers: Split Type and Integral Type. Each type has its unique characteristics and applications, catering to different needs within the market. Split Type Stirling Cycle Cryogenic Coolers consist of two separate components: the cold head and the compressor. These components are connected by a flexible transfer line, allowing for greater flexibility in installation and operation. The separation of the cold head and compressor enables the cold head to be placed in a location that requires cooling, while the compressor can be positioned elsewhere, reducing noise and vibration at the point of cooling. This type of cooler is particularly advantageous in applications where space is limited or where minimizing vibration is critical, such as in sensitive scientific instruments or medical devices. The flexibility in placement also allows for easier maintenance and servicing, as the compressor can be accessed without disturbing the cold head. On the other hand, Integral Type Stirling Cycle Cryogenic Coolers have the cold head and compressor integrated into a single unit. This design offers a more compact solution, which can be beneficial in applications where space is a significant constraint. The integral design simplifies the installation process, as there is no need for a separate transfer line, and the entire unit can be installed as a single piece. This type of cooler is often used in applications where ease of installation and operation is a priority, such as in portable or mobile systems. The compact nature of integral coolers also makes them suitable for applications where weight is a concern, such as in aerospace or defense systems. Both Split Type and Integral Type coolers have their advantages and are chosen based on the specific requirements of the application. For instance, in space applications, where minimizing weight and maximizing reliability are crucial, integral coolers may be preferred. In contrast, in laboratory settings where precision and minimal vibration are essential, split coolers might be more suitable. The choice between split and integral types often depends on factors such as the available space, the level of vibration tolerance, the ease of maintenance, and the specific cooling requirements of the application. The market for these coolers is influenced by technological advancements that continue to improve their efficiency and performance. Innovations in materials and design have led to the development of coolers that can achieve lower temperatures with greater energy efficiency. This is particularly important in applications where energy consumption is a critical consideration, such as in remote or off-grid locations. Additionally, the development of more robust and durable components has enhanced the reliability and lifespan of these coolers, making them a more attractive option for long-term applications. As industries continue to evolve and demand more sophisticated cooling solutions, the Global Stirling Cycle Cryogenic Coolers Market is expected to see continued growth. The versatility and efficiency of both Split Type and Integral Type coolers make them well-suited to meet the diverse needs of various industries, from scientific research to industrial manufacturing. The ongoing advancements in technology and the increasing demand for high-performance cooling solutions are likely to drive further innovation and expansion in this market.

Space, Defense, Biotech and Bio-Science, Medical and Pharmaceutical, Energy, Chemical, Others in the Global Stirling Cycle Cryogenic Coolers Market:

The Global Stirling Cycle Cryogenic Coolers Market finds applications across a wide range of industries, each with its unique requirements and challenges. In the space industry, these coolers are essential for maintaining the low temperatures needed for sensitive instruments and sensors on satellites and spacecraft. The ability to operate efficiently in the vacuum of space and withstand the harsh conditions of space travel makes Stirling cycle cryogenic coolers an ideal choice for space missions. They help ensure the proper functioning of scientific instruments, enabling accurate data collection and analysis. In the defense sector, Stirling cycle cryogenic coolers are used in various applications, including infrared sensors and night vision equipment. The coolers help maintain the optimal operating temperature for these devices, ensuring their accuracy and reliability in critical situations. The low vibration and high reliability of these coolers are particularly important in defense applications, where precision and dependability are paramount. In the biotech and bio-science industries, these coolers are used to preserve biological samples and materials at cryogenic temperatures. The ability to maintain stable and precise temperatures is crucial for the integrity of biological samples, which can be sensitive to temperature fluctuations. Stirling cycle cryogenic coolers provide the necessary cooling capabilities to support research and development activities in these fields, enabling scientists to conduct experiments and analyses with confidence. The medical and pharmaceutical industries also benefit from the use of Stirling cycle cryogenic coolers. In medical imaging, such as MRI machines, these coolers help maintain the low temperatures required for the superconducting magnets used in the imaging process. The coolers ensure the magnets remain in a superconducting state, allowing for high-quality imaging and accurate diagnostics. In the pharmaceutical industry, cryogenic coolers are used to store and transport temperature-sensitive drugs and vaccines, ensuring their efficacy and safety. In the energy sector, Stirling cycle cryogenic coolers are used in applications such as liquefied natural gas (LNG) production and storage. The coolers help maintain the low temperatures required for the liquefaction process, enabling the efficient storage and transportation of natural gas. The ability to achieve and maintain cryogenic temperatures is essential for the safe and efficient handling of LNG, making these coolers a critical component of the energy industry. In the chemical industry, these coolers are used in processes that require low temperatures, such as the production of certain chemicals and materials. The ability to achieve precise temperature control is essential for the quality and consistency of chemical products, and Stirling cycle cryogenic coolers provide the necessary cooling capabilities to support these processes. Other industries, such as electronics and manufacturing, also utilize Stirling cycle cryogenic coolers for various applications. The coolers are used to maintain low temperatures for sensitive electronic components, ensuring their performance and longevity. In manufacturing, the coolers are used in processes that require precise temperature control, such as the production of advanced materials and components. Overall, the Global Stirling Cycle Cryogenic Coolers Market plays a vital role in supporting a wide range of industries, each with its unique cooling requirements. The versatility and efficiency of these coolers make them an essential tool for achieving the low temperatures needed for various critical applications.

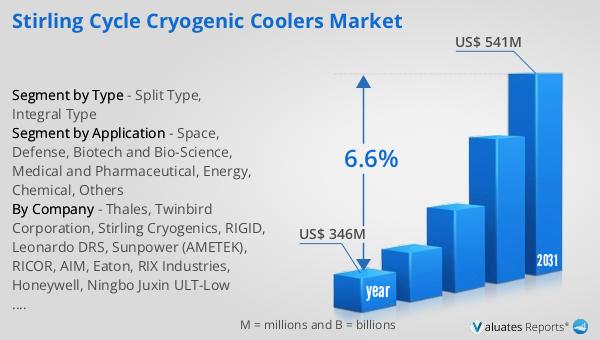

Global Stirling Cycle Cryogenic Coolers Market Outlook:

The global market for Stirling Cycle Cryogenic Coolers was valued at $346 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is projected to reach a revised size of $541 million, reflecting a compound annual growth rate (CAGR) of 6.6% during the forecast period. This growth is driven by the increasing demand for efficient and reliable cooling solutions across various industries. As technological advancements continue to enhance the performance and efficiency of Stirling cycle cryogenic coolers, their adoption is expected to rise, further fueling market growth. The market's expansion is also supported by the growing need for advanced cooling technologies in sectors such as space, defense, biotech, medical, and energy. These industries require precise and reliable cooling solutions to support their critical applications, and Stirling cycle cryogenic coolers are well-suited to meet these demands. As a result, the market is poised for continued growth, with opportunities for innovation and development in the coming years. The increasing focus on energy efficiency and sustainability is also expected to drive the adoption of these coolers, as industries seek to reduce their environmental impact while maintaining high performance and reliability.

| Report Metric | Details |

| Report Name | Stirling Cycle Cryogenic Coolers Market |

| Accounted market size in year | US$ 346 million |

| Forecasted market size in 2031 | US$ 541 million |

| CAGR | 6.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Thales, Twinbird Corporation, Stirling Cryogenics, RIGID, Leonardo DRS, Sunpower (AMETEK), RICOR, AIM, Eaton, RIX Industries, Honeywell, Ningbo Juxin ULT-Low Temperature Technology, Lihantech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |