What is Global Rosin Modified Alkyd (RMA) Resins Market?

Global Rosin Modified Alkyd (RMA) Resins Market is a specialized segment within the broader chemical industry, focusing on the production and application of resins that have been modified with rosin to enhance their properties. These resins are primarily used in coatings, inks, and adhesives due to their excellent adhesion, gloss, and flexibility. The modification with rosin, a natural resin obtained from pine trees, imparts unique characteristics to alkyd resins, making them more versatile and suitable for various industrial applications. The market for RMA resins is driven by the demand for high-performance coatings and inks, particularly in sectors such as automotive, construction, and packaging. As industries continue to seek materials that offer both performance and sustainability, RMA resins are gaining traction due to their ability to combine the benefits of natural and synthetic components. The global market is characterized by a diverse range of products tailored to meet specific application needs, with ongoing research and development efforts aimed at further enhancing the performance and environmental profile of these resins. The market's growth is supported by technological advancements and the increasing emphasis on eco-friendly and sustainable materials in industrial applications.

Short Oil, Medium Oil, Long Oil in the Global Rosin Modified Alkyd (RMA) Resins Market:

In the Global Rosin Modified Alkyd (RMA) Resins Market, the classification of resins into Short Oil, Medium Oil, and Long Oil types is based on the oil length, which refers to the percentage of oil content in the resin formulation. Short Oil alkyd resins contain less than 40% oil content and are known for their fast-drying properties and hardness. These resins are typically used in applications where quick drying and a hard finish are essential, such as in industrial coatings and certain types of inks. The lower oil content results in a higher concentration of resin, which contributes to the durability and resistance of the final product. Medium Oil alkyd resins, with an oil content ranging from 40% to 60%, offer a balance between flexibility and hardness. They are versatile and widely used in both industrial and architectural coatings. The medium oil length allows these resins to provide good adhesion, gloss, and weather resistance, making them suitable for a variety of surfaces and environmental conditions. Long Oil alkyd resins, containing more than 60% oil content, are characterized by their flexibility and ease of application. These resins are often used in architectural coatings, where a smooth, glossy finish and ease of application are desired. The higher oil content in Long Oil resins results in a softer film, which can accommodate the expansion and contraction of surfaces due to temperature changes. This flexibility makes them ideal for exterior applications, where surfaces are exposed to varying weather conditions. The choice between Short Oil, Medium Oil, and Long Oil alkyd resins depends on the specific requirements of the application, including drying time, hardness, flexibility, and environmental exposure. Each type of resin offers distinct advantages, allowing manufacturers to select the most appropriate formulation for their needs. The ongoing development of RMA resins continues to focus on enhancing these properties to meet the evolving demands of the market. As industries increasingly prioritize sustainability and performance, the ability to tailor resin formulations to specific applications is a key factor driving the growth of the Global Rosin Modified Alkyd Resins Market.

Industrial Coatings, Architectural Coatings, Inks & Printing, Others in the Global Rosin Modified Alkyd (RMA) Resins Market:

The usage of Global Rosin Modified Alkyd (RMA) Resins Market spans several key areas, including Industrial Coatings, Architectural Coatings, Inks & Printing, and other specialized applications. In the realm of Industrial Coatings, RMA resins are prized for their durability, adhesion, and resistance to environmental factors. These properties make them ideal for protecting metal surfaces, machinery, and equipment from corrosion and wear. The ability to withstand harsh industrial environments ensures that coatings made with RMA resins provide long-lasting protection, reducing maintenance costs and extending the lifespan of industrial assets. In Architectural Coatings, RMA resins are used to create paints and finishes that offer both aesthetic appeal and functional benefits. The flexibility and gloss of these resins make them suitable for both interior and exterior applications, where they provide a smooth, attractive finish that can withstand weathering and UV exposure. The use of RMA resins in architectural coatings also contributes to improved adhesion and durability, ensuring that painted surfaces maintain their appearance and integrity over time. In the Inks & Printing sector, RMA resins are utilized to produce high-quality inks that offer excellent adhesion, gloss, and color retention. These properties are essential for printing applications where clarity and vibrancy are critical, such as in packaging, labels, and promotional materials. The fast-drying nature of RMA resins also enhances the efficiency of printing processes, allowing for quicker turnaround times and higher productivity. Beyond these primary applications, RMA resins find use in a variety of other areas, including adhesives, sealants, and specialty coatings. Their versatility and performance characteristics make them suitable for a wide range of industrial and commercial applications, where they contribute to improved product performance and sustainability. As the demand for high-performance, eco-friendly materials continues to grow, the role of RMA resins in these diverse applications is expected to expand, driven by ongoing innovation and development in the field.

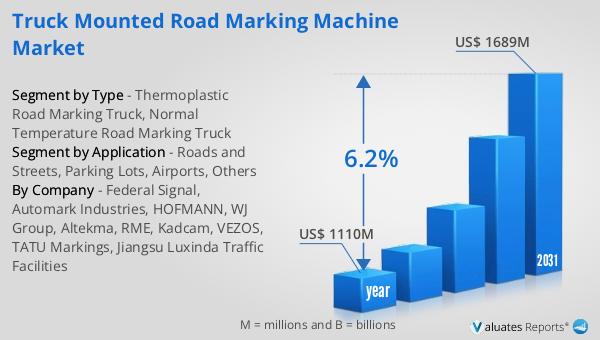

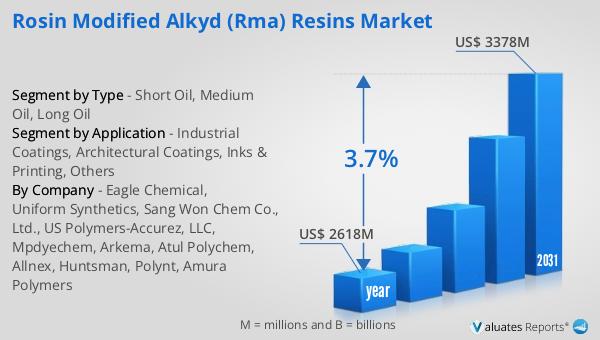

Global Rosin Modified Alkyd (RMA) Resins Market Outlook:

The global market for Rosin Modified Alkyd (RMA) Resins was valued at approximately $2,618 million in 2024. This market is anticipated to grow steadily, reaching an estimated size of $3,378 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.7% over the forecast period. The steady increase in market value reflects the rising demand for RMA resins across various industries, driven by their unique properties and versatility. The growth is supported by the expanding applications of RMA resins in sectors such as industrial coatings, architectural coatings, and inks & printing. As industries continue to seek materials that offer both performance and sustainability, RMA resins are gaining traction due to their ability to combine the benefits of natural and synthetic components. The market's growth is further bolstered by technological advancements and the increasing emphasis on eco-friendly and sustainable materials in industrial applications. The projected growth of the RMA resins market underscores the importance of these materials in meeting the evolving needs of industries worldwide. As the market continues to expand, manufacturers and stakeholders are likely to focus on innovation and development to enhance the performance and environmental profile of RMA resins, ensuring their continued relevance and competitiveness in the global market.

| Report Metric | Details |

| Report Name | Rosin Modified Alkyd (RMA) Resins Market |

| Accounted market size in year | US$ 2618 million |

| Forecasted market size in 2031 | US$ 3378 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Eagle Chemical, Uniform Synthetics, Sang Won Chem Co., Ltd., US Polymers-Accurez, LLC, Mpdyechem, Arkema, Atul Polychem, Allnex, Huntsman, Polynt, Amura Polymers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |