What is Global Rigid Chain Lifting Platform Market?

The Global Rigid Chain Lifting Platform Market is a specialized segment within the broader lifting and material handling industry. These platforms utilize rigid chains instead of traditional wire ropes or belts, offering enhanced stability and precision in lifting operations. Rigid chain technology allows for vertical lifting with minimal sway, making it ideal for environments where precision is crucial. The market encompasses a variety of applications, including industrial, logistics, automotive, and construction sectors, where the need for reliable and efficient lifting solutions is paramount. The platforms are designed to handle different load capacities, catering to diverse operational requirements. As industries continue to automate and seek more efficient material handling solutions, the demand for rigid chain lifting platforms is expected to grow. This growth is driven by the platforms' ability to improve operational efficiency, safety, and reliability. Additionally, advancements in technology are leading to the development of more sophisticated and versatile lifting platforms, further expanding their applicability across various sectors. The market is characterized by a mix of established players and emerging companies, all striving to innovate and capture a share of this evolving market.

Load Capacity 2 Tons or Less, Load Capacity 2 Tons or More in the Global Rigid Chain Lifting Platform Market:

In the Global Rigid Chain Lifting Platform Market, load capacity is a critical factor that determines the suitability of a platform for specific applications. Platforms with a load capacity of 2 tons or less are typically used in environments where lighter loads are handled. These platforms are ideal for applications in smaller industrial settings, logistics operations, and certain automotive tasks where precision and control are more important than sheer lifting power. They offer the advantage of being more compact and easier to integrate into existing systems, making them a popular choice for businesses looking to enhance their material handling capabilities without significant infrastructure changes. On the other hand, platforms with a load capacity of 2 tons or more are designed for heavy-duty applications. These platforms are essential in industries such as construction, where the ability to lift heavy materials and equipment is crucial. They are also used in large-scale industrial operations where the movement of substantial loads is a regular requirement. The robust design of these platforms ensures they can withstand the stresses associated with lifting heavy loads, providing reliability and safety in demanding environments. The choice between these two categories of platforms depends largely on the specific needs of the operation, including the types of materials being handled, the frequency of lifting operations, and the spatial constraints of the work environment. Companies must carefully assess their operational requirements to select the appropriate platform that will deliver the best performance and return on investment. As the market continues to evolve, manufacturers are focusing on enhancing the capabilities of both categories of platforms, incorporating advanced technologies to improve efficiency, safety, and ease of use. This includes the integration of smart technologies that allow for real-time monitoring and control, further enhancing the functionality and appeal of rigid chain lifting platforms across various industries.

Industrial, Logistics, Automotive, Construction, Others in the Global Rigid Chain Lifting Platform Market:

The Global Rigid Chain Lifting Platform Market finds extensive usage across several key sectors, each with unique requirements and challenges. In the industrial sector, these platforms are indispensable for handling materials and components in manufacturing processes. They facilitate the efficient movement of goods within factories, reducing manual labor and increasing productivity. The precision and stability offered by rigid chain technology are particularly beneficial in environments where accuracy is paramount, such as in the assembly of delicate components or the handling of hazardous materials. In the logistics sector, rigid chain lifting platforms play a crucial role in streamlining operations. They are used in warehouses and distribution centers to move goods quickly and safely, optimizing the flow of materials and reducing bottlenecks. The ability to handle varying load capacities makes them versatile tools in logistics, where the types of goods being moved can vary significantly. In the automotive industry, these platforms are used in both manufacturing and maintenance operations. They assist in the assembly of vehicles by lifting heavy components into place with precision, ensuring that production lines run smoothly and efficiently. Additionally, they are used in maintenance facilities to lift vehicles for repairs and inspections, providing a safe and stable platform for technicians to work on. The construction industry also benefits significantly from rigid chain lifting platforms. They are used to lift heavy construction materials and equipment, facilitating the efficient and safe execution of construction projects. The platforms' ability to handle heavy loads with precision is particularly valuable in this sector, where the safety and reliability of lifting operations are critical. Beyond these sectors, rigid chain lifting platforms are used in various other applications, including in the aerospace industry for the assembly and maintenance of aircraft, and in the energy sector for the handling of heavy equipment and materials. The versatility and reliability of these platforms make them an essential tool in any industry where lifting operations are a key component of the workflow. As industries continue to evolve and seek more efficient and safe material handling solutions, the demand for rigid chain lifting platforms is expected to grow, driven by their ability to meet the diverse needs of different sectors.

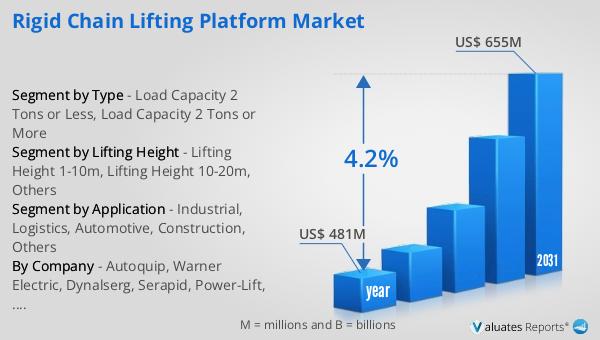

Global Rigid Chain Lifting Platform Market Outlook:

The global market for Rigid Chain Lifting Platforms was valued at approximately $481 million in 2024. This market is anticipated to expand, reaching an estimated size of $655 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. This upward trajectory is indicative of the increasing demand for efficient and reliable lifting solutions across various industries. The market's expansion is driven by several factors, including the growing need for automation in material handling processes and the continuous advancements in lifting technology. As industries strive to enhance operational efficiency and safety, the adoption of rigid chain lifting platforms is expected to rise. These platforms offer significant advantages over traditional lifting solutions, including improved stability, precision, and load handling capabilities. The market is characterized by a mix of established players and new entrants, all competing to innovate and capture a share of this growing market. As the demand for more sophisticated and versatile lifting solutions increases, manufacturers are focusing on developing platforms that incorporate advanced technologies, such as smart controls and real-time monitoring systems. This focus on innovation is expected to further drive the market's growth, as companies seek to differentiate their offerings and meet the evolving needs of their customers. Overall, the Global Rigid Chain Lifting Platform Market is poised for significant growth, driven by the increasing demand for efficient and reliable lifting solutions across various sectors.

| Report Metric | Details |

| Report Name | Rigid Chain Lifting Platform Market |

| Accounted market size in year | US$ 481 million |

| Forecasted market size in 2031 | US$ 655 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Lifting Height |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Autoquip, Warner Electric, Dynalserg, Serapid, Power-Lift, Wippermann, Gradin Machinery, Neon Intelligence Technology, Dgrande, Grundei Hebetische Verladetechnik, Jinan Zhongding Lifting Machinery, Xunte, GRADIN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |