What is Global Package Forming Flux Market?

The Global Package Forming Flux Market is a specialized segment within the broader electronics manufacturing industry. This market focuses on the production and distribution of flux materials used in the assembly of electronic packages. Flux is a chemical cleaning agent that facilitates the soldering process by removing oxidation from metal surfaces, ensuring a strong bond between components. The demand for package forming flux is driven by the increasing complexity and miniaturization of electronic devices, which require precise and reliable soldering techniques. As technology advances, the need for high-performance flux materials that can accommodate smaller and more intricate designs becomes crucial. The market is characterized by a variety of flux types, each tailored to specific applications and performance requirements. Manufacturers in this market are continually innovating to develop flux formulations that offer improved thermal stability, reduced residue, and enhanced compatibility with lead-free soldering processes. The global reach of this market is evident as electronics manufacturing is a worldwide industry, with significant production hubs in Asia, North America, and Europe. As the electronics industry continues to grow, the Global Package Forming Flux Market is expected to expand, driven by the ongoing demand for advanced electronic devices and the need for efficient manufacturing processes.

Water-soluble, Rosin-based, Other in the Global Package Forming Flux Market:

In the Global Package Forming Flux Market, flux types are categorized into water-soluble, rosin-based, and other formulations, each serving distinct purposes in the electronics manufacturing process. Water-soluble fluxes are designed to be easily cleaned with water after the soldering process, making them an environmentally friendly option. They are particularly useful in applications where post-soldering cleaning is essential to prevent corrosion and ensure the longevity of electronic components. These fluxes are often used in industries where cleanliness is paramount, such as in medical devices and aerospace electronics. Rosin-based fluxes, on the other hand, are derived from natural resin and are known for their excellent soldering performance and reliability. They are widely used in traditional electronics manufacturing due to their ability to provide a strong bond and protect against oxidation. However, they require the use of solvents for cleaning, which can be a drawback in terms of environmental impact and cost. Other flux types in the market include no-clean fluxes, which are designed to leave minimal residue that does not require cleaning, and synthetic fluxes, which are engineered for specific applications requiring unique properties. The choice of flux type depends on various factors, including the specific requirements of the electronic assembly, the desired level of cleanliness, and environmental considerations. As the electronics industry evolves, manufacturers are continually developing new flux formulations to meet the changing demands of the market. This includes creating fluxes that are compatible with lead-free soldering processes, which are becoming increasingly important due to environmental regulations. The development of advanced flux materials is crucial for ensuring the reliability and performance of electronic devices, particularly as they become more complex and miniaturized. In summary, the Global Package Forming Flux Market is characterized by a diverse range of flux types, each with its own advantages and limitations. The ongoing innovation in flux formulations is driven by the need to address the challenges of modern electronics manufacturing, including the demand for cleaner, more efficient, and environmentally friendly solutions.

Chip Attach, Ball Attach in the Global Package Forming Flux Market:

The Global Package Forming Flux Market plays a crucial role in the assembly of electronic components, particularly in the areas of chip attach and ball attach processes. In chip attach, flux is used to facilitate the bonding of semiconductor chips to substrates or other components. This process is critical in the production of integrated circuits and other microelectronic devices. The flux helps to remove oxidation from the surfaces being joined, ensuring a strong and reliable connection. The choice of flux in chip attach applications depends on factors such as the type of solder used, the materials being bonded, and the specific requirements of the assembly process. For instance, water-soluble fluxes may be preferred in applications where post-soldering cleaning is necessary to prevent corrosion and ensure the longevity of the device. In contrast, no-clean fluxes may be used in applications where cleaning is not feasible or where minimal residue is acceptable. Ball attach is another important application of package forming flux, particularly in the assembly of ball grid array (BGA) packages. In this process, flux is used to attach solder balls to the substrate, which are then reflowed to form electrical connections. The quality of the flux used in ball attach is critical, as it directly impacts the reliability and performance of the final product. Flux formulations for ball attach must provide excellent wetting properties to ensure uniform solder ball attachment and prevent defects such as bridging or voids. Additionally, the flux must be compatible with the materials used in the assembly and capable of withstanding the thermal stresses of the reflow process. As electronic devices continue to become more complex and miniaturized, the demand for high-performance flux materials in chip attach and ball attach applications is expected to grow. Manufacturers in the Global Package Forming Flux Market are continually innovating to develop flux formulations that meet the evolving needs of the electronics industry, including the demand for lead-free soldering processes and environmentally friendly solutions. In conclusion, the usage of package forming flux in chip attach and ball attach processes is essential for ensuring the reliability and performance of electronic devices. The ongoing development of advanced flux materials is crucial for addressing the challenges of modern electronics manufacturing and supporting the growth of the industry.

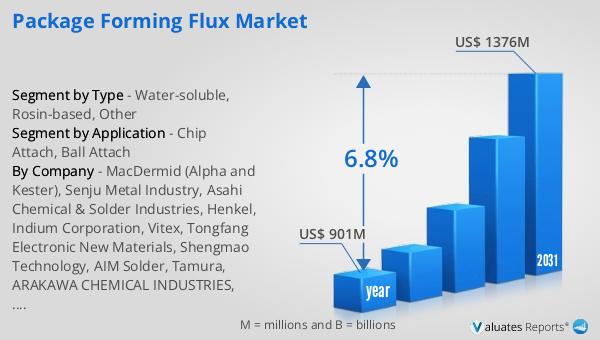

Global Package Forming Flux Market Outlook:

The global market for Package Forming Flux was valued at $901 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is projected to reach a revised size of $1,376 million, reflecting a compound annual growth rate (CAGR) of 6.8% during the forecast period. This growth is indicative of the increasing demand for advanced electronic devices and the corresponding need for efficient and reliable manufacturing processes. The expansion of the market is driven by several factors, including the ongoing miniaturization of electronic components, the shift towards lead-free soldering processes, and the growing emphasis on environmentally friendly manufacturing practices. As the electronics industry continues to evolve, the demand for high-performance flux materials that can accommodate the complexities of modern electronic assemblies is expected to rise. Manufacturers in the Global Package Forming Flux Market are likely to focus on developing innovative flux formulations that offer improved thermal stability, reduced residue, and enhanced compatibility with a wide range of soldering processes. The projected growth of the market underscores the importance of package forming flux in the electronics manufacturing industry and highlights the ongoing need for advanced materials that can support the development of next-generation electronic devices.

| Report Metric | Details |

| Report Name | Package Forming Flux Market |

| Accounted market size in year | US$ 901 million |

| Forecasted market size in 2031 | US$ 1376 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MacDermid (Alpha and Kester), Senju Metal Industry, Asahi Chemical & Solder Industries, Henkel, Indium Corporation, Vitex, Tongfang Electronic New Materials, Shengmao Technology, AIM Solder, Tamura, ARAKAWA CHEMICAL INDUSTRIES, Changxian New Materials, Superior Flux & Mfg. Co., Inventec Performance Chemicals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |