What is Global Micro High Pressure Constant Flow Pump Market?

The Global Micro High Pressure Constant Flow Pump Market is a specialized segment within the broader pump industry, focusing on pumps that deliver a consistent flow rate under high-pressure conditions. These pumps are crucial in applications where precision and reliability are paramount, such as in laboratories, industrial processes, and various manufacturing sectors. The market is characterized by its emphasis on innovation and technological advancement, as manufacturers strive to develop pumps that are not only efficient but also compact and capable of handling extreme pressures. The demand for these pumps is driven by their ability to maintain a steady flow rate, which is essential for processes that require exact measurements and consistent performance. As industries continue to evolve and require more sophisticated equipment, the Global Micro High Pressure Constant Flow Pump Market is expected to grow, driven by the need for precision and efficiency in high-pressure applications. The market's growth is also supported by the increasing adoption of automation and the need for equipment that can seamlessly integrate into automated systems. Overall, the Global Micro High Pressure Constant Flow Pump Market plays a critical role in supporting various industries by providing reliable and precise pumping solutions.

Motor Driven Type, Electromagnetic Driven Type in the Global Micro High Pressure Constant Flow Pump Market:

In the Global Micro High Pressure Constant Flow Pump Market, two primary types of pumps are prevalent: Motor Driven Type and Electromagnetic Driven Type. Motor Driven Type pumps are powered by electric motors, which convert electrical energy into mechanical energy to drive the pump. These pumps are known for their robustness and ability to handle high-pressure applications with ease. They are often used in industries where durability and reliability are crucial, such as in chemical processing and water treatment. The motor-driven pumps are designed to provide a constant flow rate, making them ideal for applications that require precise control over fluid movement. Their design allows for easy integration into existing systems, and they are often favored for their efficiency and long service life. On the other hand, Electromagnetic Driven Type pumps operate using electromagnetic forces to move fluids. These pumps are typically smaller and more compact than their motor-driven counterparts, making them suitable for applications where space is limited. Electromagnetic pumps are known for their precision and ability to deliver a consistent flow rate, even under varying pressure conditions. They are often used in laboratory settings and in industries where precise fluid control is essential, such as in pharmaceuticals and analytical testing. The electromagnetic pumps are designed to minimize pulsation, ensuring a smooth and continuous flow of fluids. This makes them particularly useful in applications where even minor fluctuations in flow rate can have significant impacts on the process. Both Motor Driven and Electromagnetic Driven pumps have their unique advantages and are chosen based on the specific requirements of the application. While motor-driven pumps offer durability and high-pressure handling capabilities, electromagnetic pumps provide precision and compactness. The choice between the two often depends on factors such as the nature of the fluid being pumped, the required flow rate, and the specific conditions of the application. As the Global Micro High Pressure Constant Flow Pump Market continues to grow, manufacturers are focusing on enhancing the performance and efficiency of both types of pumps to meet the evolving needs of various industries. This includes developing pumps that are more energy-efficient, have a smaller footprint, and can handle a wider range of fluids and pressures. The ongoing advancements in pump technology are expected to drive further growth in the market, as industries continue to seek reliable and efficient solutions for their high-pressure pumping needs.

Analytical Testing Industry, Pharmaceutical Industry, Fine Chemical Industry, Energy Industry, Others in the Global Micro High Pressure Constant Flow Pump Market:

The Global Micro High Pressure Constant Flow Pump Market finds extensive usage across various industries, each with its unique requirements and applications. In the Analytical Testing Industry, these pumps are essential for delivering precise and consistent flow rates, which are crucial for accurate testing and analysis. They are used in chromatography and other analytical techniques where maintaining a constant flow of solvents or reagents is vital for obtaining reliable results. The precision and reliability of these pumps ensure that the analytical processes are not compromised, leading to more accurate and reproducible data. In the Pharmaceutical Industry, micro high pressure constant flow pumps play a critical role in drug formulation and production. They are used to deliver precise amounts of active ingredients and excipients, ensuring that the final product meets the required specifications. The ability to maintain a consistent flow rate is essential in pharmaceutical manufacturing, where even minor deviations can affect the quality and efficacy of the drugs. These pumps are also used in research and development, where precise control over fluid delivery is necessary for developing new formulations and conducting experiments. The Fine Chemical Industry relies on these pumps for their ability to handle aggressive and corrosive chemicals while maintaining a steady flow rate. This is crucial in processes such as chemical synthesis and purification, where precise control over fluid movement is necessary to achieve the desired chemical reactions and product purity. The pumps' ability to withstand harsh chemical environments ensures their longevity and reliability in these demanding applications. In the Energy Industry, micro high pressure constant flow pumps are used in various applications, including oil and gas extraction, power generation, and renewable energy systems. They are essential for maintaining the flow of fluids under high-pressure conditions, which is critical for the efficient operation of energy systems. The pumps' ability to deliver a consistent flow rate ensures that energy production processes are not disrupted, leading to more efficient and reliable energy generation. Other industries, such as food and beverage, water treatment, and automotive, also benefit from the use of these pumps. In the food and beverage industry, they are used for precise dosing and mixing of ingredients, ensuring product consistency and quality. In water treatment, they are used to deliver chemicals and additives with precision, ensuring the effective treatment of water. In the automotive industry, they are used in various applications, including fuel injection and lubrication systems, where maintaining a constant flow rate is essential for optimal performance. Overall, the Global Micro High Pressure Constant Flow Pump Market plays a vital role in supporting a wide range of industries by providing reliable and precise pumping solutions. The versatility and precision of these pumps make them indispensable in applications where maintaining a consistent flow rate is critical for achieving the desired outcomes. As industries continue to evolve and demand more sophisticated equipment, the market for micro high pressure constant flow pumps is expected to grow, driven by the need for precision and efficiency in high-pressure applications.

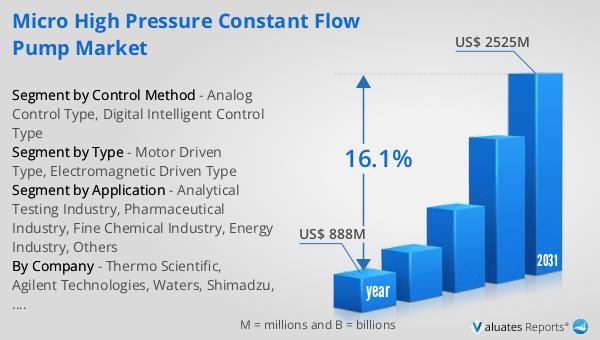

Global Micro High Pressure Constant Flow Pump Market Outlook:

The global market for Micro High Pressure Constant Flow Pumps was valued at $888 million in 2024, and it is anticipated to expand significantly, reaching an estimated size of $2,525 million by 2031. This growth represents a compound annual growth rate (CAGR) of 16.1% over the forecast period. This impressive growth trajectory underscores the increasing demand for these specialized pumps across various industries. The market's expansion is driven by the need for precision and reliability in high-pressure applications, as well as the ongoing advancements in pump technology. As industries continue to evolve and require more sophisticated equipment, the demand for micro high pressure constant flow pumps is expected to rise. These pumps are essential for maintaining a consistent flow rate, which is crucial for processes that require exact measurements and consistent performance. The market's growth is also supported by the increasing adoption of automation and the need for equipment that can seamlessly integrate into automated systems. Overall, the Global Micro High Pressure Constant Flow Pump Market is poised for significant growth, driven by the need for precision and efficiency in high-pressure applications. As industries continue to evolve and demand more sophisticated equipment, the market for micro high pressure constant flow pumps is expected to grow, driven by the need for precision and efficiency in high-pressure applications.

| Report Metric | Details |

| Report Name | Micro High Pressure Constant Flow Pump Market |

| Accounted market size in year | US$ 888 million |

| Forecasted market size in 2031 | US$ 2525 million |

| CAGR | 16.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Control Method |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Thermo Scientific, Agilent Technologies, Waters, Shimadzu, KNAUER, Sykam, DSM, Harvard Apparatus, Teledyne ISCO, Cetoni, FLOWELL, Tuthill, LEWA, Eastwin Scientific Equipments, Tianjin Hengao Technology, Prefluid, Chromai |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |