What is Global Medical Grade FEP Heat Shrink Tubing Market?

The Global Medical Grade FEP Heat Shrink Tubing Market is a specialized segment within the broader medical device industry, focusing on the production and distribution of heat shrink tubing made from Fluorinated Ethylene Propylene (FEP). This type of tubing is renowned for its excellent chemical resistance, high-temperature tolerance, and non-stick properties, making it ideal for various medical applications. FEP heat shrink tubing is primarily used to provide insulation, protection, and mechanical support to delicate medical components. Its transparency allows for easy inspection of the underlying components, which is crucial in medical settings. The market for this tubing is driven by the increasing demand for minimally invasive surgical procedures, which require precise and reliable medical devices. Additionally, the growing emphasis on patient safety and the need for high-quality medical equipment further fuel the demand for medical-grade FEP heat shrink tubing. As healthcare systems worldwide continue to advance, the need for such specialized materials is expected to grow, making this market an essential component of the medical device industry.

Shrink Ratios 1.3:1, Shrink Ratios 1.6:1, Shrink Ratios 2:1, Other in the Global Medical Grade FEP Heat Shrink Tubing Market:

Shrink ratios in the Global Medical Grade FEP Heat Shrink Tubing Market refer to the degree to which the tubing can contract when heat is applied. These ratios are crucial because they determine how tightly the tubing can fit around the components it is meant to protect. The 1.3:1 shrink ratio indicates that the tubing can shrink to 1.3 times its original diameter. This ratio is typically used in applications where only a slight reduction in size is needed, providing a snug fit without exerting too much pressure on the underlying components. It's ideal for applications where the components are delicate or where minimal space is available for the tubing to contract. The 1.6:1 shrink ratio offers a bit more flexibility, allowing the tubing to shrink to 1.6 times its original diameter. This is suitable for applications that require a tighter fit than the 1.3:1 ratio can provide, but where the components are still relatively sensitive to pressure. This ratio is often used in situations where the tubing needs to conform more closely to the shape of the components, providing enhanced protection and insulation. The 2:1 shrink ratio is one of the most commonly used in the market, as it allows the tubing to shrink to half its original diameter. This ratio is ideal for applications that require a secure fit and where the components can withstand a bit more pressure. It's often used in situations where the tubing needs to provide robust protection against environmental factors such as moisture, chemicals, and abrasion. The 2:1 ratio is versatile and can be used in a wide range of medical applications, making it a popular choice among manufacturers and healthcare providers. Other shrink ratios are also available, catering to specific needs and applications. These ratios can vary widely, offering even more flexibility in terms of fit and protection. For instance, some specialized applications may require tubing that can shrink to a much smaller size, providing an extremely tight fit for maximum protection. These other ratios are often used in niche applications where standard ratios do not meet the specific requirements of the medical device or procedure. Overall, the availability of different shrink ratios in the Global Medical Grade FEP Heat Shrink Tubing Market ensures that healthcare providers and manufacturers can find the perfect fit for their specific needs, enhancing the performance and safety of medical devices.

Vascular Interventional Devices, Endoscopes, Sensors and Probes, Other in the Global Medical Grade FEP Heat Shrink Tubing Market:

The Global Medical Grade FEP Heat Shrink Tubing Market finds extensive usage in various medical applications, including vascular interventional devices, endoscopes, sensors, and probes. In vascular interventional devices, FEP heat shrink tubing is used to provide insulation and protection to guidewires, catheters, and stents. These devices are crucial in procedures such as angioplasty and stent placement, where precision and reliability are paramount. The tubing's ability to withstand high temperatures and resist chemical degradation ensures that these devices function optimally, reducing the risk of complications during procedures. In endoscopes, FEP heat shrink tubing is used to cover and protect the delicate optical fibers and electronic components. Endoscopes are essential tools in minimally invasive surgeries, allowing doctors to view and operate on internal organs without making large incisions. The tubing's transparency and flexibility make it ideal for this application, as it does not obstruct the view while providing the necessary protection. Sensors and probes also benefit from the use of FEP heat shrink tubing. These components are often used in diagnostic and monitoring equipment, where accuracy and reliability are critical. The tubing provides insulation and protection against environmental factors, ensuring that the sensors and probes deliver accurate readings. Additionally, the tubing's non-stick properties prevent the accumulation of debris, which can interfere with the performance of these sensitive components. Other applications of FEP heat shrink tubing in the medical field include its use in surgical instruments, diagnostic equipment, and laboratory devices. The tubing's versatility and durability make it an invaluable component in the design and manufacture of a wide range of medical devices. As the demand for advanced medical technologies continues to grow, the usage of FEP heat shrink tubing is expected to expand, further solidifying its position in the medical device industry.

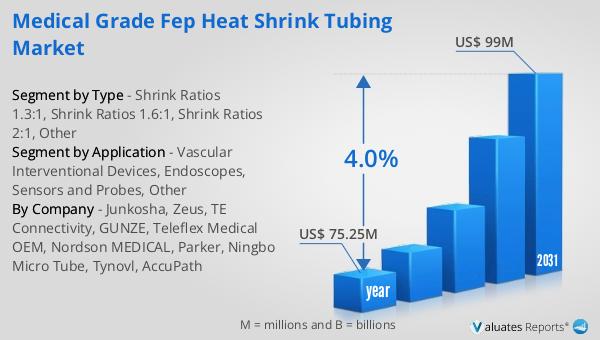

Global Medical Grade FEP Heat Shrink Tubing Market Outlook:

The global market for Medical Grade FEP Heat Shrink Tubing was valued at approximately $75.25 million in 2024. This market is anticipated to grow steadily, reaching an estimated size of $99 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.0% over the forecast period. The steady increase in market size can be attributed to several factors, including the rising demand for minimally invasive surgical procedures and the growing emphasis on patient safety and high-quality medical equipment. As healthcare systems worldwide continue to advance, the need for specialized materials like FEP heat shrink tubing is expected to grow. This tubing is essential for providing insulation, protection, and mechanical support to delicate medical components, making it a critical component in the design and manufacture of medical devices. The market's growth is also driven by the increasing adoption of advanced medical technologies and the expanding applications of FEP heat shrink tubing in various medical fields. As the market continues to evolve, manufacturers and healthcare providers are likely to invest in research and development to enhance the performance and safety of medical devices, further fueling the demand for medical-grade FEP heat shrink tubing.

| Report Metric | Details |

| Report Name | Medical Grade FEP Heat Shrink Tubing Market |

| Accounted market size in year | US$ 75.25 million |

| Forecasted market size in 2031 | US$ 99 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Junkosha, Zeus, TE Connectivity, GUNZE, Teleflex Medical OEM, Nordson MEDICAL, Parker, Ningbo Micro Tube, Tynovl, AccuPath |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |